Need Full Specifications?

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

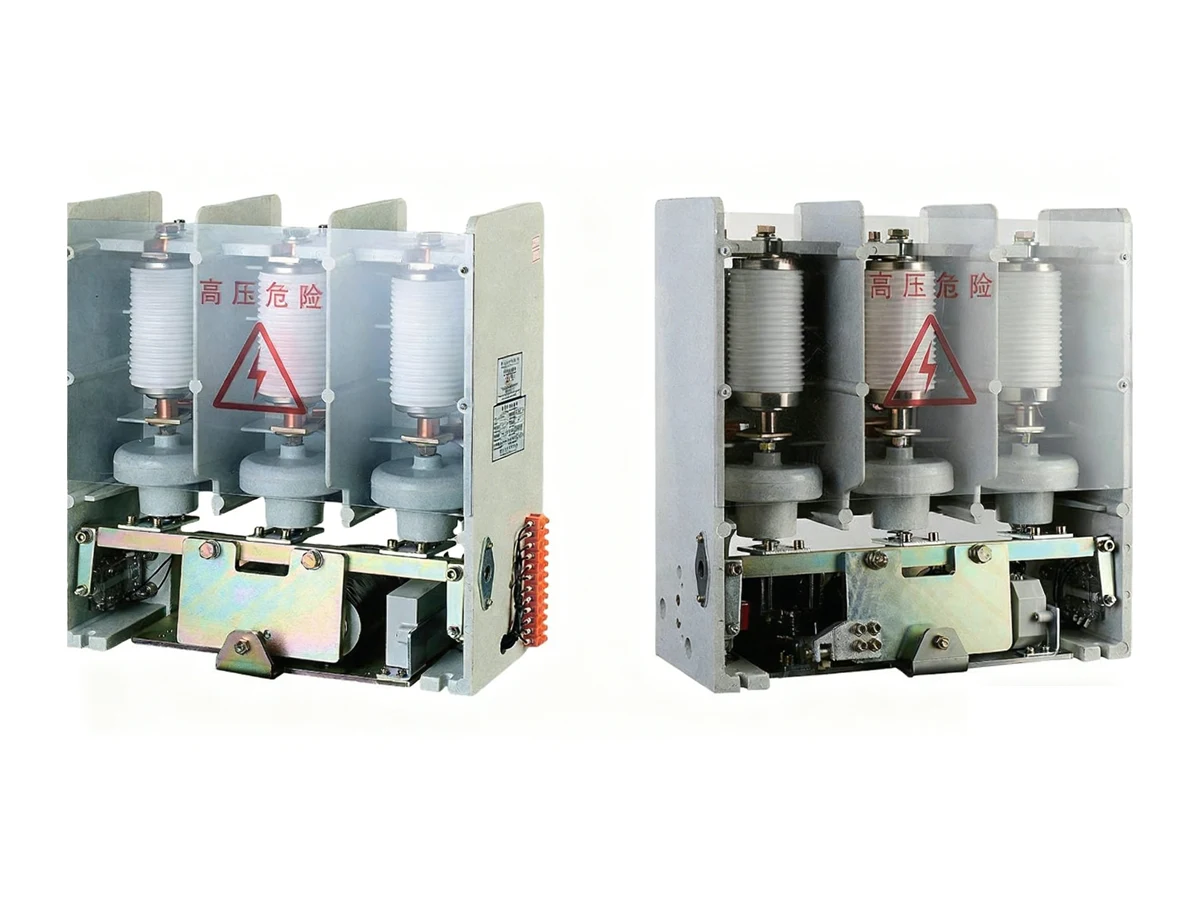

XBRELE JCZ Series offers reliable medium voltage switching solutions for power systems. Featuring the JCZ5 3-phase vacuum contactor (7.2kV / 12kV) for F-C cabinets and motor control, and the specialized JCZ1 single-pole vacuum contactor (12kV) for electric locomotives and single-phase loads. Designed with a robust frame structure for frequent operation and long mechanical life.

The XBRELE JCZ vacuum contactor series offers a comprehensive range of medium voltage switching solutions, split into two distinct categories: the JCZ5 (Three-phase) and the JCZ1 (Single-pole). Both series feature a robust frame structure that integrates the vacuum interrupter and operating mechanism into a single, easy-to-maintain unit.

The JCZ5 series (7.2kV / 12kV) is the standard choice for indoor power distribution. It is widely used in F-C (Fuse-Contactor) cabinets for controlling high-voltage motors and transformers. With rated currents up to 630A and optional mechanical latching, it provides reliable control for frequent operation scenarios like pump stations and capacitive load loops.

The JCZ1 series (12kV) is a specialized single-pole (monopole) vacuum contactor. It is specifically engineered for single-phase power systems, such as electric locomotives and polysilicon reduction furnaces. Its compact design allows for flexible installation in restricted spaces while maintaining high insulation levels and arc-extinguishing capability.

For a broader view of XBRELE’s medium-voltage switching portfolio, please visit the Vacuum Contactor pillar page .

Browse the technical specifications and installation drawings for our JCZ5 (Three-phase) and JCZ1 (Single-pole) series. These frame-structure contactors are designed for reliable high-voltage switching in industrial and power distribution applications.

The JCZ5 series adopts a “whole structured” frame design, integrating the vacuum interrupter and operating mechanism into a robust unit. Applicable to AC 50Hz power systems with rated working voltages of 7.2kV and 12kV, and rated currents up to 630A.

These contactors are capable of frequent operation and possess strong making/breaking abilities. They are extensively used in F-C (Fuse-Contactor) cabinets, reactive power compensation devices, and for controlling motors and transformers.

The table below compares the technical parameters for both the 7.2kV and 12kV models. Please refer to the dimensions section for installation details.

Main technical parameters — JCZ5 Series

Comparison of JCZ5-□/7.2 and JCZ5-□/12 models.

| No. | Item | Unit | JCZ5-□/7.2 | JCZ5-□/12 |

|---|---|---|---|---|

| 1 | Rated voltage | kV | 7.2 | 12 |

| 2 | Rated current | A | 160, 250, 400, 630 | 160, 250, 400, 630 |

| 3 | Power frequency withstand voltage (1 min) | kV | 32 | 42 |

| 4 | Lightning impulse withstand voltage | kV | 60 | 75 |

| 5 | Rated breaking capacity (AC-3) | A | 8Ie (25 times) | 8Ie (25 times) |

| 6 | Rated closing capacity (AC-3) | A | 10Ie (100 times) | 10Ie (100 times) |

| 7 | Rated short-time resistance current | kA | 10Ie (1.6~6.3) | 10Ie (1.6~6.3) |

| 8 | Rated current peak tolerance | kA | 25Ie (4~16) | 25Ie (4~16) |

| 9 | Overload withstand current | kA | 15Ie (2.4~9.45) | 15Ie (2.4~9.45) |

| 10 | Short circuit breaking and closing | A | 10Ie (O-180s-CO 1 time) | 10Ie (O-180s-CO 1 time) |

| 11 | Rated contact gap | mm | 4 ± 0.5 | 6 ± 0.5 |

| 12 | Overtravel | mm | ≥ 1.5 | ≥ 1.5 |

| 13 | Closing synchronism | ms | ≤ 2 | ≤ 2 |

| 14 | Mechanical life | 10⁴ times | 50 | 50 |

| 15 | Electrical life (AC3 / AC4) | 10⁴ times | 25 / 10 | 25 / 10 |

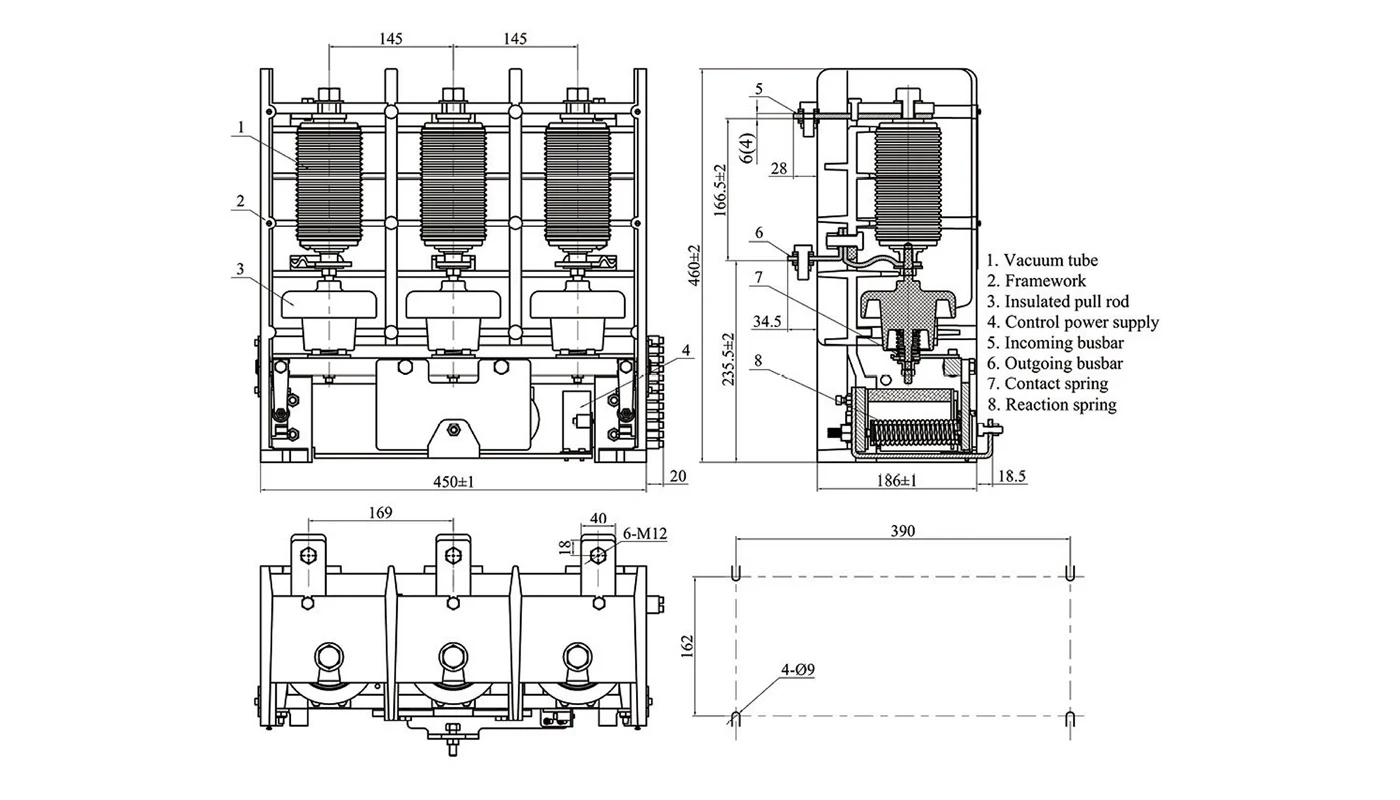

Outline & mounting dimensions — JCZ5 Series

Outline dimensions differ slightly between voltage classes. Ensure you are viewing the correct drawing for your specific voltage requirement.

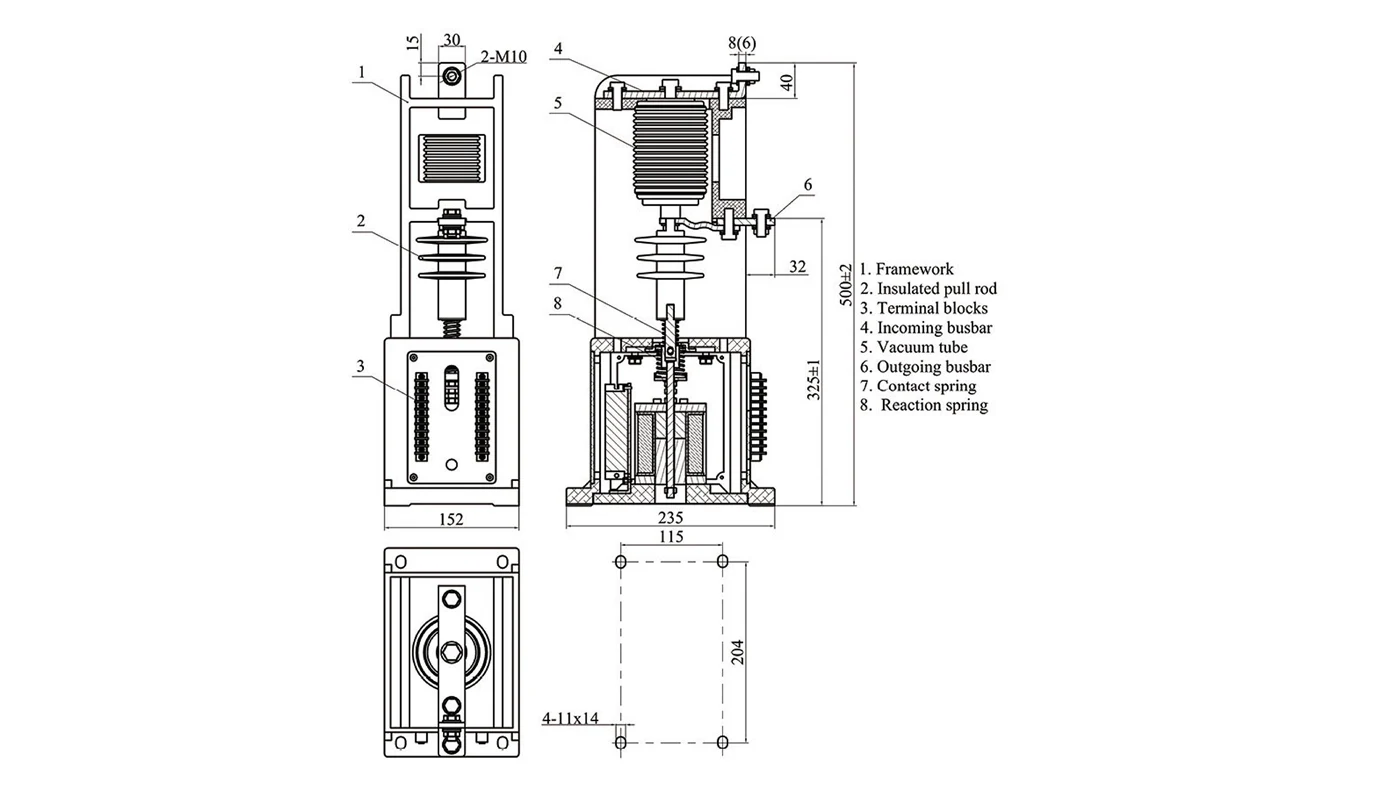

The JCZ1-□/12 series is a specialized monopole high-voltage vacuum contactor designed for single-phase power systems (AC 50Hz) with rated voltages up to 12kV.

It is particularly suitable for remote opening/closing of single-phase loads such as refining polysilicon reduction furnaces, electric locomotives, and harmonic elimination circuits. It features arc elimination capabilities, reduced capacity, and is often used as a host switch in specialized industrial applications.

See the table below for specific electrical ratings for the JCZ1 series.

Main technical parameters — JCZ1 Series

Ratings for JCZ1-□/12 Single-pole vacuum contactor.

| No. | Item | Unit | JCZ1-□/12 |

|---|---|---|---|

| 1 | Rated voltage | kV | 12 |

| 2 | Rated current | A | 160, 250, 400, 630 |

| 3 | Power frequency withstand voltage | kV | 42 |

| 4 | Lightning impulse withstand voltage | kV | 75 |

| 5 | Rated breaking capacity | A | 8Ie (25 times) |

| 6 | Rated closing capacity | A | 10Ie (100 times) |

| 7 | Rated short-time resistance current | kA | 10Ie (1.6~6.3) |

| 8 | Rated current peak tolerance | kA | 25Ie (4~16) |

| 9 | Overload withstand current | kA | 15Ie (2.4~9.45) |

| 10 | Short circuit breaking and closing | A | 10Ie (O-180s-CO 1 time) |

| 11 | Rated contact gap | mm | 5.5 ± 0.5 |

| 12 | Overtravel | mm | ≥ 1.5 |

| 13 | Mechanical life | 10⁴ times | 50 |

| 14 | Electrical life (AC3 / AC4) | 10⁴ times | 25 / 10 |

Outline & mounting dimensions — JCZ1-□/12

Use the drawing below for layout planning of single-phase control cabinets.

The JCZ series is designed with flexibility in mind. From mechanical latching options to specialized single-pole configurations, XBRELE provides tailored solutions that integrate seamlessly into modern switchgear and control systems.

JCZ contactors offer versatile holding mechanisms to suit different control circuit requirements and energy efficiency goals.

The frame structure and compact footprint make JCZ5 ideal for Fuse-Contactor (F-C) combinations in motor control centers.

Addressing specialized industrial needs with unique pole configurations and contact technologies.

The reliability of the JCZ series stems from a rigorous manufacturing process. From the vacuum interrupter integration to the final mechanical tuning, every step is controlled to ensure stable operation in critical F-C circuits.

XBRELE oversees the entire assembly of the JCZ vacuum contactor, ensuring that the electromagnetic system perfectly matches the vacuum interrupter’s characteristics.

Vacuum interrupters are precision-mounted into the insulating frame. We strictly control alignment to prevent mechanical stress and ensure optimal dielectric strength.

The closing/opening coils (AC/DC) and magnetic latches are installed. We verify the pick-up and drop-out voltages to guarantee reliable operation under fluctuating grid conditions.

Critical parameters such as contact gap (4±0.5mm / 5.5±0.5mm) and overtravel (≥1.5mm) are fine-tuned to maximize electrical life and minimize bounce.

For 3-phase JCZ5 models, pole closing synchronism is adjusted to ≤2ms, ensuring balanced switching and reducing stress on connected motors or capacitors.

Each unit undergoes power-frequency withstand voltage tests and multiple mechanical operation cycles before being sealed for shipment.

We adhere to strict IEC and national standards, ensuring every JCZ contactor meets the demands of heavy-duty industrial applications.

Test reports are archived for full traceability.

Custom FAT (Factory Acceptance Test) plans available for large projects.

Whether you need a single replacement for maintenance or batch supply for a new switchgear line, XBRELE ensures your JCZ5 and JCZ1 vacuum contactors arrive safely and on schedule.

We maintain a flexible manufacturing line to support both urgent maintenance needs and planned project rollouts.

Vacuum interrupters are sensitive components. Our packaging is designed to withstand the rigors of international freight.

Our engineering team assists you throughout the design and integration phase of your MV panel.

Technical insights for engineers selecting JCZ vacuum contactors for medium voltage switchgear, F-C cabinets, and single-phase industrial applications.