Need Full Specifications?

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

Selecting vacuum contactors for installations above 1,000 meters demands engineering adjustments that standard catalog specifications do not address. Reduced atmospheric pressure at elevation weakens external insulation strength and diminishes convective cooling capacity—two effects that compound to limit safe operating current and voltage withstand margins. This guide provides the technical framework for specifying vacuum contactors that perform reliably in high-altitude mining operations, mountain infrastructure, and elevated industrial facilities.

Air thins as elevation increases. At 3,000 meters, atmospheric pressure drops to roughly 70% of sea-level values. This pressure reduction triggers two parallel performance degradation mechanisms that standard ratings do not account for.

Standard vacuum contactor specifications assume operation at or below 1,000 meters altitude with ambient temperatures not exceeding 40°C. These reference conditions define the baseline for all published current ratings, voltage withstand values, and thermal limits. Exceed either parameter, and the equipment enters territory where catalog specifications no longer guarantee reliable performance.

Dielectric strength reduction occurs because fewer air molecules per unit volume means reduced resistance to electrical breakdown. External air gaps between phases, phase-to-ground clearances, and creepage paths along insulator surfaces all lose dielectric capability as altitude increases. Corona discharge initiates at lower voltages. Surface flashover thresholds drop proportionally with air density.

Convective cooling degradation follows the same physics. Heat removal from current-carrying components depends on air absorbing and carrying away thermal energy. Thinner air transfers heat less efficiently. Main contacts, electromagnetic coils, and terminal connections all run hotter under identical electrical loads when installed at elevation.

One critical exception exists. The vacuum interrupter at the heart of every vacuum contactor operates in hard vacuum—typically below 10⁻³ Pa. This internal environment remains constant regardless of external atmospheric conditions. Whether installed at sea level or atop a 5,000-meter Andean peak, the vacuum gap between contacts maintains identical arc interruption capability.

The altitude problem concentrates entirely on external systems: the insulation structure surrounding the interrupter, the thermal management of current-carrying parts, and the supporting components that operate in atmospheric air.

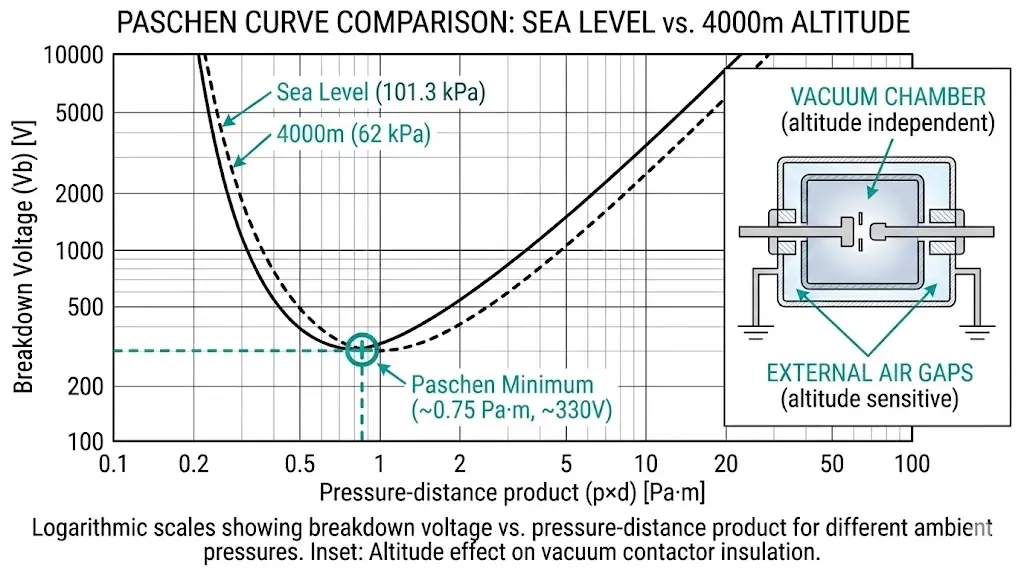

Atmospheric pressure decreases exponentially with elevation, fundamentally altering the dielectric behavior of air surrounding vacuum contactors. At sea level, standard atmospheric pressure measures approximately 101.3 kPa. At 4,000 meters, pressure drops to roughly 62 kPa—a 39% decrease that directly impacts voltage withstand capability.

The physics governing this phenomenon involves electron avalanche formation. At sea level, air molecules are densely packed, limiting electron mean free paths to approximately 0.07 μm. When altitude increases to 4,000 meters, electron mean free paths extend significantly. This longer path allows electrons to accelerate to higher energies between collisions, initiating ionization cascades at lower voltage thresholds.

The critical relationship follows Paschen’s minimum, where breakdown voltage Vb reaches its lowest point at a specific pressure-distance product (p × d). For air at standard conditions, this minimum occurs at approximately p × d ≈ 0.75 Pa·m, producing Vb ≈ 330 V. At higher altitudes, the curve shifts, meaning that gaps designed for sea-level operation may fall into unfavorable breakdown regions.

IEC 62271-1 specifies that switchgear designed for altitudes exceeding 1,000 meters must account for reduced dielectric strength of ambient air. The standard establishes correction factors: for every 1,000 meters above the baseline, external insulation voltage ratings typically require derating by approximately 1.25% per 100 meters.

While the internal vacuum interrupter maintains its inherent dielectric strength (typically 40–60 kV/mm across the contact gap), external creepage and clearance distances become the limiting factors. Typical vacuum contactor designs specify creepage distances of 20–25 mm/kV at sea level, but high-altitude applications generally require increases of 40–60% to maintain equivalent dielectric withstand capability.

[Expert Insight: Field Observations from High-Altitude Deployments]

- In mining installations across the Tibetan Plateau (3,800–4,500 m), external flashover occurred at voltages 25–30% below sea-level ratings when altitude correction was neglected

- Testing across 35 high-altitude substations revealed surface flashover on external insulators at voltages 18–22% lower than catalog specifications

- Corona discharge becomes visible at night on terminal connections operating near rated voltage at elevations above 3,500 m

- Dust accumulation compounds altitude effects by reducing effective creepage distances

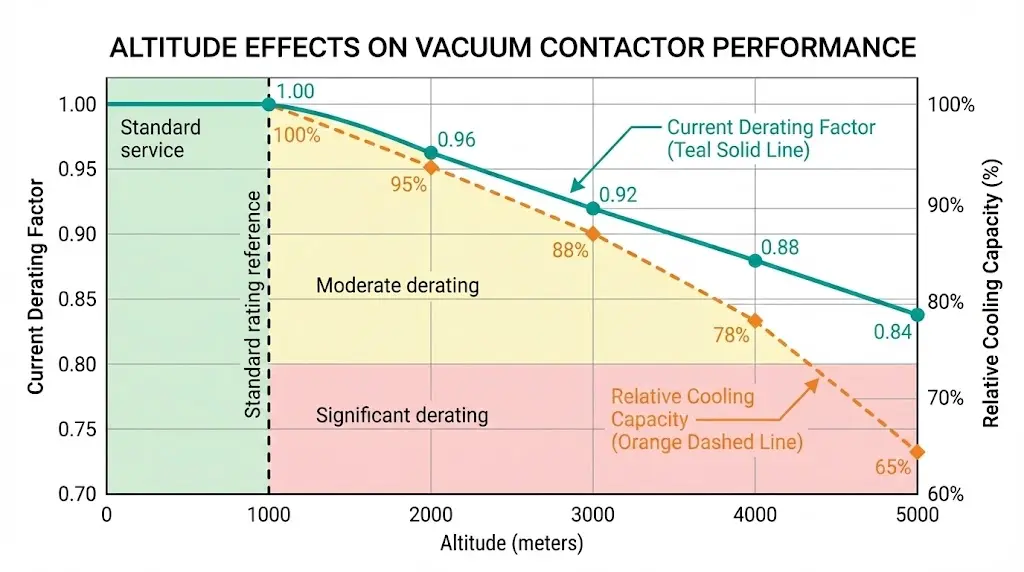

Current derating compensates for reduced convective cooling at elevation. The methodology is straightforward: apply a multiplier that reduces allowable current proportionally to the cooling capacity loss.

| Altitude Range (m) | Atmospheric Pressure (kPa) | Derating Factor | 400A Rated → Derated Current |

|---|---|---|---|

| ≤1,000 | ≥90 | 1.00 | 400A |

| 1,000–1,500 | 85–90 | 0.98 | 392A |

| 1,500–2,000 | 80–85 | 0.95 | 380A |

| 2,000–2,500 | 75–80 | 0.92 | 368A |

| 2,500–3,000 | 70–75 | 0.88 | 352A |

| 3,000–3,500 | 65–70 | 0.85 | 340A |

| 3,500–4,000 | 62–65 | 0.82 | 328A |

| 4,000–5,000 | 54–62 | 0.75–0.80 | 300–320A |

Worked example: A motor control application requires 400A continuous current at a copper mine located at 3,800 meters elevation. Applying the 0.82 derating factor means a 400A-rated vacuum contactor can safely carry only 328A. To maintain the full 400A requirement, specify a contactor rated 400A ÷ 0.82 = 488A minimum. A 500A or 630A rated unit provides adequate margin.

When ambient temperature also exceeds 40°C, combine both factors. For 45°C ambient at 3,500 m altitude: 0.85 (altitude) × 0.95 (temperature) = 0.81 combined factor. This multiplicative relationship means high-altitude, high-temperature sites face substantial derating—sometimes exceeding 25%.

The oversizing strategy often proves more economical than enhanced cooling systems. A 630A vacuum contactor operating at 400A experiences reduced thermal stress, extended contact life, and lower maintenance requirements. The upfront cost premium typically recovers through reduced lifetime operating costs.

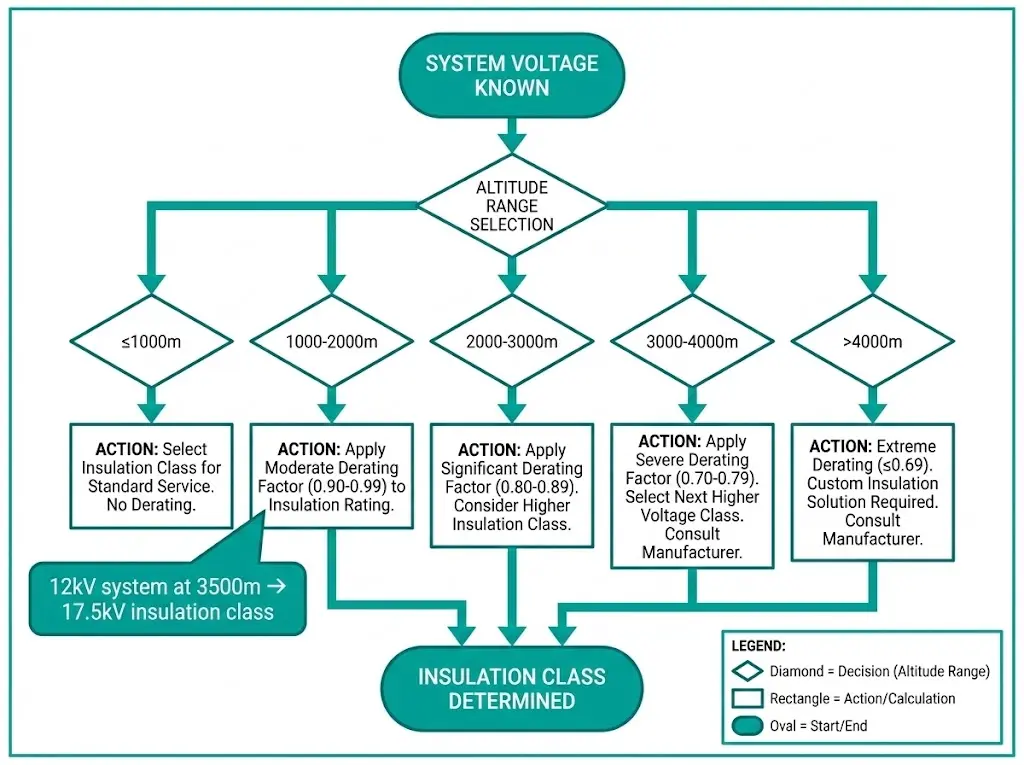

Voltage withstand capability requires the same systematic correction as current ratings. The dielectric correction factor quantifies how much external insulation strength decreases with altitude.

| Altitude (m) | Dielectric Correction Factor | 12kV System → Required Insulation Class |

|---|---|---|

| ≤1,000 | 1.00 | 12kV |

| 1,500 | 0.97 | 12kV |

| 2,000 | 0.95 | 12kV (verify margins) |

| 2,500 | 0.91 | 15kV or 17.5kV |

| 3,000 | 0.88 | 17.5kV |

| 3,500 | 0.84 | 17.5kV |

| 4,000 | 0.80 | 17.5kV or 24kV |

| 5,000 | 0.72 | 24kV |

The standard approach selects the next-higher insulation class when the corrected withstand voltage falls below adequate margins. For a 12kV system operating at 3,500 meters, the effective insulation capability of a 12kV-class contactor drops to approximately 12 × 0.84 = 10.1kV equivalent—insufficient margin for reliable operation. Specifying 17.5kV insulation class restores adequate dielectric reserves.

Basic Insulation Level (BIL) verification follows the same logic. A contactor with 75kV BIL at sea level provides only 63kV effective BIL at 4,000 meters. If the system requires 75kV BIL, specify equipment rated 95kV or higher.

Creepage distance requirements scale inversely with the correction factor. A 12kV vacuum contactor requiring 250mm total creepage at sea level needs approximately 250 ÷ 0.80 = 312mm at 4,000 meters—a 25% increase that impacts overall equipment dimensions.

[Expert Insight: Insulation Specification Pitfalls]

- Creepage distance alone does not guarantee performance—surface contamination at altitude (common in mining) further reduces effective insulation

- Silicone rubber insulators outperform porcelain in high-altitude outdoor applications due to hydrophobic surface recovery

- Phase barriers between poles require the same altitude correction as external clearances

- BIL testing at manufacturing altitude may not reflect installed performance at higher elevations

When oversizing the vacuum contactor is impractical, enhanced cooling systems can partially compensate for reduced convective heat transfer at altitude.

Forced ventilation increases volumetric airflow across heat-generating components. Size fans for 20–30% greater CFM capacity compared to sea-level requirements. Account for fan motor derating at altitude—the motor driving the cooling system also loses output in thin air. Filter systems become essential in dusty mountain or mining environments where contamination ingress would otherwise compromise insulation surfaces.

Heat sink enhancement adds thermal mass and dissipation area. Oversized copper or aluminum terminals, supplementary heat sinks on main conductors, and extended busbar lengths within enclosures all contribute to thermal management. These passive measures add cost and space but require no ongoing maintenance.

Duty cycle adjustment works for intermittent loads. Reducing switching frequency allows thermal recovery between operations. A contactor rated for 300 operations per hour at sea level might be limited to 200 operations per hour at 4,000 meters. This approach suits batch processes or infrequent motor starting but fails for continuous-duty applications.

The trade-off analysis typically favors oversized contactors for continuous loads and enhanced cooling for space-constrained installations with intermittent duty. Combined strategies—moderate oversizing plus improved ventilation—often provide the most robust solution for critical applications.

For applications requiring vacuum circuit breakers alongside contactors, apply the same altitude correction methodology to all medium-voltage switching equipment in the installation.

Copper and lithium mining operations across the Andes routinely install medium-voltage switchgear at 4,000–5,000 meters elevation. Telecommunications facilities and astronomical observatories occupy sites above 5,000 meters. These installations generate practical knowledge that supplements theoretical calculations.

Visible corona becomes common on terminal connections and busbar supports when equipment operates near rated voltage at elevations above 3,500 meters. The characteristic purple glow, often visible only at night, indicates approaching flashover thresholds. Maintenance personnel at one Chilean mining operation reported corona activity on 12kV equipment that had operated without issue at lower-altitude sites.

Bolted connections run measurably hotter at altitude. Thermal imaging surveys at Peruvian copper mines showed terminal temperatures 15–25°C higher than equivalent sea-level installations under similar loading. This temperature rise accelerates joint degradation, requiring more frequent torque verification and contact resistance testing.

Dust contamination compounds altitude effects by depositing conductive paths across creepage surfaces. Mountain mining environments combine thin air with high particulate levels—a challenging combination for external insulation. Enclosed switchgear with filtered ventilation outperforms open designs in these conditions.

Spare parts inventories must include altitude-rated components. Standard replacement contactors or auxiliary devices sourced for emergency repairs may not match the enhanced specifications of original equipment. The indoor vs outdoor VCB selection guide addresses enclosure considerations that apply equally to vacuum contactors in exposed mountain installations.

High-altitude vacuum contactor selection extends beyond catalog specifications. Engineering support for altitude-specific calculations, custom insulation configurations, and documentation for compliance verification distinguishes capable manufacturers from commodity suppliers.

Technical consultation should address site-specific conditions: exact elevation, ambient temperature range, contamination severity, duty cycle requirements, and enclosure constraints. Generic derating tables provide starting points, but optimized solutions require application engineering.

XBRELE’s vacuum contactor manufacturing capabilities include altitude-rated configurations with enhanced insulation classes, extended creepage distances, and thermal management provisions designed for specific installation elevations. Request technical specifications matched to your site altitude and operating requirements.

External Reference: IEC 62271-106 — IEC 62271-106 standard for AC contactors

Q: At what altitude do vacuum contactors require derating?

A: Derating typically begins above 1,000 meters elevation, with correction factors increasing progressively—expect approximately 15–20% current reduction at 3,500 meters and 20–25% at 4,500 meters.

Q: Does altitude affect the vacuum interrupter’s arc interruption capability?

A: No. The vacuum interrupter operates at internal pressures below 10⁻³ Pa regardless of external atmospheric conditions, maintaining consistent arc extinction performance at any installation altitude.

Q: Can I install a standard 12kV vacuum contactor at 4,000 meters without modification?

A: Generally not recommended. The dielectric correction factor at 4,000 meters reduces external insulation effectiveness by approximately 20%, typically requiring 17.5kV insulation class for adequate voltage withstand margins on 12kV systems.

Q: How do combined altitude and temperature derating factors work together?

A: Multiply the individual factors. For example, at 3,000 meters (0.88 altitude factor) with 50°C ambient (approximately 0.90 temperature factor), the combined derating reaches 0.88 × 0.90 = 0.79, reducing allowable current to 79% of catalog rating.

Q: Is forced cooling always necessary for high-altitude vacuum contactor installations?

A: Not always. Oversizing the contactor rating often provides adequate thermal margin without active cooling—a 630A-rated unit operating at 400A load typically maintains acceptable temperatures even at 4,000 meters elevation.

Q: What maintenance adjustments apply to high-altitude vacuum contactors?

A: Increase inspection frequency for bolted connections (thermal degradation accelerates), monitor insulation surfaces for corona damage or contamination tracking, and ensure spare parts match altitude-rated specifications rather than standard sea-level components.

Q: Do control coils and auxiliary contacts also need altitude ratings?

A: Yes. Electromagnetic coils experience reduced cooling just like main circuits, and auxiliary contacts rated for sea-level thermal conditions may overheat at elevation under continuous duty.