Need Full Specifications?

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

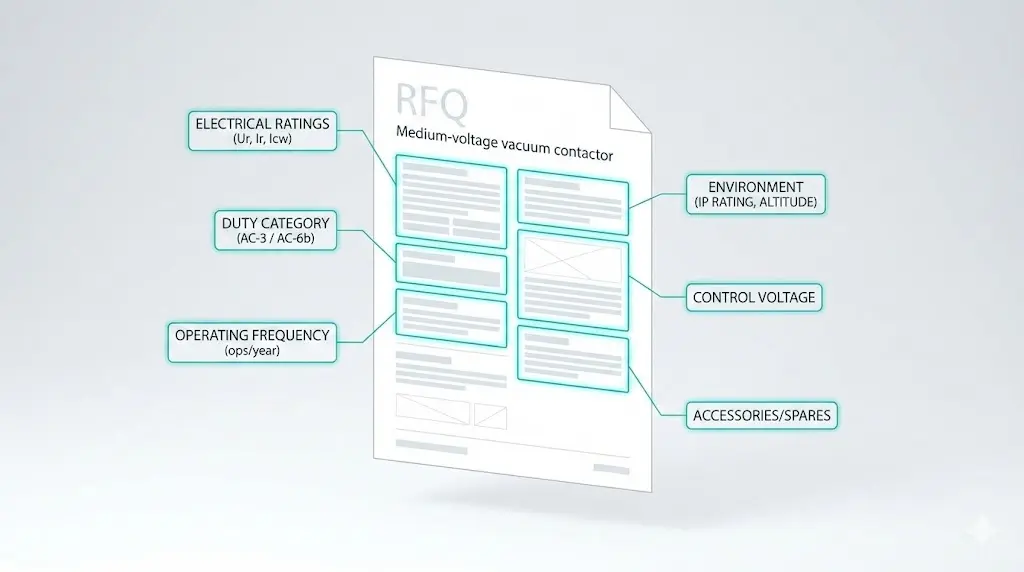

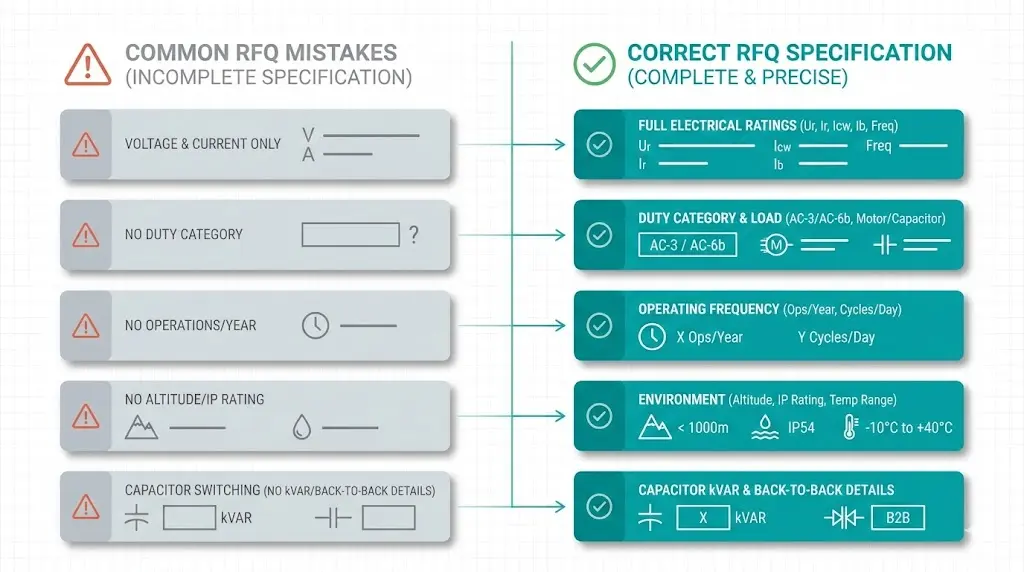

Generic vacuum contactor RFQs generate quotes that don’t match requirements. “12 kV, 400 A vacuum contactor” describes perhaps 500 different product variants across manufacturers—some rated for motor starting duty at 50 operations/day, others for capacitor switching at 10,000 operations/year, still others for transformer switching or general load breaking.

The manufacturer receiving an incomplete RFQ faces two choices: quote conservatively (overspecified, expensive solution), or quote optimistically (underspecified, fails in service). Neither serves the buyer. The overspecified quote loses on price to competitors who guessed lower duty requirements. The underspecified contactor fails after 6 months when the buyer discovers their “general purpose” contactor can’t handle daily capacitor bank switching.

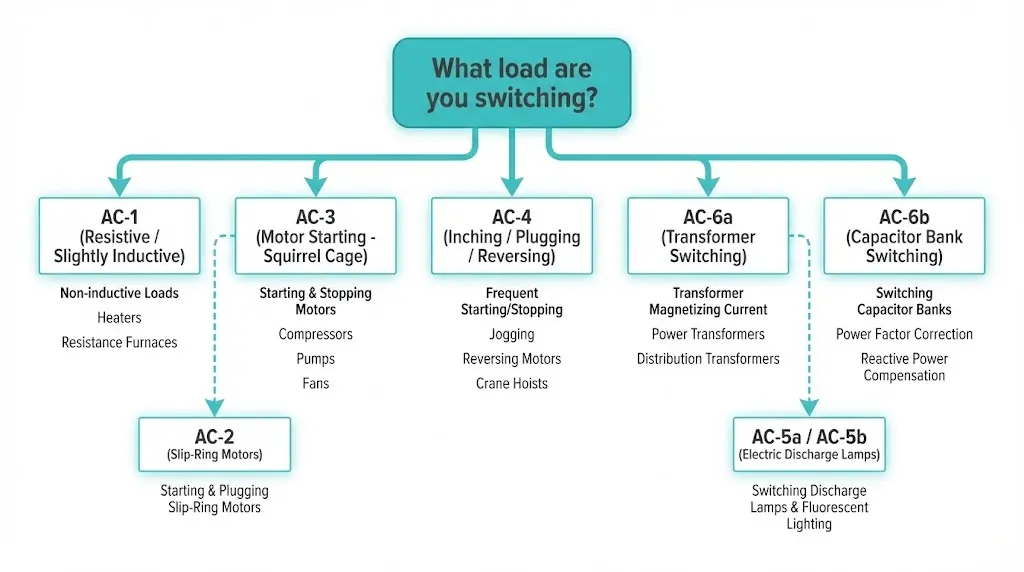

Vacuum contactors differ from circuit breakers in critical ways that RFQs must address. Circuit breakers primarily interrupt fault currents—specification focuses on short-circuit rating. Contactors primarily switch loads repeatedly—specification must define operational duty, switching frequency, load type (resistive/inductive/capacitive), and mechanical endurance requirements. Missing these parameters guarantees wrong selection.

This guide provides the complete RFQ template procurement engineers need when specifying vacuum contactors for motor control, capacitor switching, transformer switching, and load break applications in 3.6–40.5 kV systems.

Rated voltage (Ur):

Rated current (Ir):

Short-time withstand current (Icw):

Making and breaking capacity:

Duty category (per IEC 62271-106):

Example specification: “AC-3 motor starting duty, 400 A motor FLA, 2,400 A inrush (6× FLA)”

Operations per day/year:

Load power factor:

Motor starting (AC-3/AC-4):

Capacitor switching (AC-6b):

Transformer switching (AC-6a):

General load break:

Ambient temperature:

Enclosure protection:

Atmospheric conditions:

Mounting:

Dimensions and weight:

Operating mechanism:

Control voltage:

Design and testing standards:

Specify: “Contactor shall comply with IEC 62271-106, with type test certificates provided.”

Type test reports required:

Routine tests required (for each delivered unit):

Quality certifications:

Number and type:

Position indication:

Mechanical interlocks:

Electrical interlocks:

Built-in protection:

Monitoring capabilities (for smart contactors):

Quantity:

Delivery schedule:

Packaging:

Initial spare parts:

Long-term availability:

Technical support:

Standard warranty:

Performance guarantees:

VACUUM CONTACTOR REQUEST FOR QUOTATION

Project: ________________________ Date: ____________

Buyer: __________________________ Contact: ___________

1. ELECTRICAL RATINGS

- Rated voltage (Ur): ______ kV

- Rated current (Ir): ______ A continuous at ____°C ambient

- Short-time withstand (Icw): ______ kA for ____ seconds

- Making capacity (Icm): ______ kA peak

- Breaking capacity (Ib): ______ A (specify resistive/inductive/capacitive)

- Rated frequency: ______ Hz

2. DUTY TYPE AND APPLICATION

- Duty category per IEC 62271-106: AC-___

- Load description: _______________________

- Rated operational current: ______ A

- Operations per day: ______ Operations per year: ______

- Load power factor: ______ (if applicable)

[If motor starting]

- Motor power: ______ kW/HP

- Motor FLA: ______ A

- Starting current: ______ A (____× FLA)

- Starting method: DOL / Star-Delta / Soft Start / VFD

[If capacitor switching]

- Capacitor bank size: ______ kVAR

- Number of units: ______

- Detuning reactor: Yes/No, if yes: ______ mH

- Back-to-back switching: Yes/No

- Required mechanical endurance: ______ operations minimum

[If transformer switching]

- Transformer rating: ______ kVA/MVA

- No-load current: ______ A

- Inrush current: ______ A for ______ ms

3. ENVIRONMENTAL CONDITIONS

- Operating temperature: ____°C to ____°C

- Storage temperature: ____°C to ____°C

- Altitude: ______ m above sea level

- Humidity: ______ % RH, condensing/non-condensing

- Contamination level: Clean / Moderate Dust / Heavy Dust / Corrosive

- IP rating required: IP____

- Vibration/seismic requirements: ________________

4. MECHANICAL & INSTALLATION

- Mounting: Fixed / Withdrawable / Drawable

- Installation location: Indoor / Outdoor / Semi-outdoor

- Operating mechanism: Spring / Magnetic Actuator / Manual / Other

- Space constraints (if any): W____mm × H____mm × D____mm

- Maximum weight (if limited): ______ kg

5. CONTROL & AUXILIARY

- Closing coil voltage: ______ VDC/VAC

- Trip coil voltage: ______ VDC/VAC

- Auxiliary contacts required: ____ NO + ____ NC

- Position indication: Mechanical / Electrical / Both

- Mechanical interlocks: Yes/No, describe: __________

- Electrical interlocks: Undervoltage / Shunt trip / Other

- Operation counter: Yes/No

- Communication protocol (if smart contactor): _______

6. STANDARDS & TESTING

- Design standard: IEC 62271-106 / IEEE C37.012 / Other: ______

- Type test certificates required: Yes/No

- Routine test required: Per IEC 62271-106 / Custom: ______

- Factory acceptance test (FAT): Required / Optional

- Quality certifications: ISO 9001 / ISO 14001 / Other: ______

7. COMMERCIAL REQUIREMENTS

- Quantity: ______ units (initial), ______ potential future

- Delivery required by: __________

- Packaging: International shipping / Domestic / Special: ______

- Initial spare parts required: Yes/No, specify: __________

- Spare parts availability guarantee: ______ years minimum

- Commissioning support: Required / Not required

- Training: Required / Not required (specify duration: ____)

- Local service center: Required / Preferred / Not critical

- Warranty: Minimum ______ months

8. DOCUMENTATION REQUIRED WITH QUOTE

[ ] Detailed technical datasheet

[ ] Dimensional drawings (PDF + CAD)

[ ] Type test certificates

[ ] Quality certifications (ISO 9001, etc.)

[ ] Operation and maintenance manuals (draft or sample)

[ ] Spare parts list with pricing

[ ] Local service center locations and contact details

[ ] Reference installations (similar application, provide contact)

[ ] Delivery schedule and lead time

[ ] Itemized pricing (base unit, options, spare parts, services)

9. SPECIAL REQUIREMENTS OR NOTES

________________________________________________

________________________________________________

10. EVALUATION CRITERIA

Technical compliance: ____%

Price: ____%

Delivery time: ____%

After-sales support: ____%

Other: ________________: ____%

SUBMISSION DEADLINE: ____________

Submit to: ________________________

Contact for clarifications: ____________ (email/phone)

| Mistake | Consequence | Solution |

|---|---|---|

| Omitting duty type | Manufacturer guesses—either overpriced or underspec | Always specify AC-1 through AC-6b category |

| Specifying only voltage/current | 500+ variants match; quote doesn’t fit actual need | Include application, operations/year, load type |

| No altitude specified | Contactor derated at site elevation, overheats or fails dielectrically | State actual installation altitude (>1,000 m critical) |

| “Capacitor switching” without capacitor size | Manufacturer can’t determine inrush/making capacity | Specify total kVAR, number of units, detuning reactor |

| “Similar to [competitor model]” | Lazy specification leads to non-comparable quotes | Define requirements independently, not by competitor product |

| No mechanical endurance requirement | Standard 10,000-op contactor fails in high-frequency application | State operations/year; capacitor duty needs 50,000+ |

| Forgetting control voltage | Quoted contactor has 220 VDC coil, your system is 125 VDC | Specify both closing and trip coil voltages |

| No spare parts/support discussion | Contactor works great but manufacturer has no local support | Require local service center, spare parts availability guarantee |

External Reference: IEC 62271-106 — IEC 62271-106 standard for AC contactors

Q1: What’s the difference between making capacity and breaking capacity?

A: Making capacity (Icm) is peak current contactor can close onto (typically 2.5× rated short-circuit withstand for motor inrush/capacitor energization). Breaking capacity (Ib) is RMS current contactor can safely interrupt. Example: 12 kV contactor might have 40 kA making, 16 kA short-time withstand, but only 400 A breaking capacity—designed to close onto high inrush but not interrupt faults.

Q2: How do I determine required mechanical endurance for my application?

A: Calculate total operations over desired life: (operations/day × 365 × years). Example: Motor started 3×/day for 20-year life = 3 × 365 × 20 = 21,900 operations—specify 30,000+ mechanical endurance for safety margin. Capacitor switching (daily): 365 × 20 = 7,300 minimum, specify 50,000+ due to severe electrical stress.

Q3: Can I specify “equivalent to [competitor model]” instead of detailed requirements?

A: Not recommended—creates legal ambiguity and prevents apple-to-apple comparison. Different manufacturers interpret “equivalent” differently. Better: obtain competitor datasheet, extract key specifications, include those as requirements. This allows multiple manufacturers to quote fairly.

Q4: What altitude correction factor should I apply?

A: Per IEC 60694, correction factor Ka = 1 + 0.012(H – 1000) where H is altitude in meters. At 2,500 m: Ka = 1 + 0.012(2,500 – 1,000) = 1.18. Either specify contactor rated 1.18× nominal voltage or accept 1/1.18 = 0.85 (15% current derating). Always state site altitude in RFQ.

Q5: How specific should I be about capacitor bank configuration?

A: Very specific—manufacturers need: total bank kVAR, number of individual capacitor units, connection (wye/delta), detuning reactor value (if present), existing energized capacitors on bus (back-to-back switching), and switching frequency. Missing any parameter forces manufacturer to guess inrush current, leading to over/under-specification.

Q6: Should I request FAT (factory acceptance test) for all contactor purchases?

A: For critical applications (capacitor switching, high-duty motor starting, expensive equipment protection): Yes—FAT confirms performance before shipment. For standard applications with proven manufacturer track record: Optional (adds cost and delivery time). Always require FAT for custom/first-time configurations.

Q7: What warranty period should I specify for vacuum contactors?

A: Standard: 24 months from commissioning or 30 months from delivery. Capacitor switching duty: Request extended warranty (36 months) due to higher electrical stress. Also specify mechanical/electrical endurance guarantees: “Minimum 50,000 mechanical operations, 10,000 electrical operations at rated current” for capacitor duty.