Need Full Specifications?

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

Mining environments present the most demanding conditions for vacuum circuit breakers, requiring careful specification across three critical factors: dust infiltration, mechanical vibration, and thermal extremes. In deployments across 40+ underground mining substations in Australia and South Africa, equipment failures correlate directly with inadequate environmental specifications rather than inherent component defects.

Standard industrial VCB ratings assume benign service conditions—clean air, stable foundations, moderate temperatures. Mining substations face all three hostile factors simultaneously. A breaker designed for 30 years of service in a controlled environment may degrade in 3–5 years when dust, vibration, and heat act together.

This checklist provides systematic guidance for specifying vacuum circuit breakers that survive mining conditions.

A 12 kV vacuum circuit breaker installed in an underground copper mine tripped unexpectedly after 14 months of service. Post-failure inspection revealed three simultaneous degradation mechanisms: fine rock dust had created conductive tracking paths across insulating surfaces; continuous vibration from nearby conveyor systems had loosened mechanism fasteners; elevated ambient temperatures had accelerated insulation aging beyond design parameters.

This breaker carried a 20-year design life rating. It failed in just over one year.

The Compounding Effect

These stressors multiply rather than add. Dust combined with elevated temperature accelerates tracking because heat concentrates conductive contaminants. Vibration combined with dust accelerates mechanical wear as particles infiltrate moving parts. Heat combined with vibration accelerates fastener loosening through differential thermal expansion cycling.

Economic Reality

Unplanned electrical outages in mining operations cost $30,000 to $150,000 per hour depending on commodity prices and production scale. A single breaker failure halting production for 8 hours can exceed the total procurement cost of properly specified switchgear.

Specification Philosophy

Design for worst-case simultaneous occurrence. Assume maximum dust exposure coincides with maximum vibration and maximum temperature. Apply margin beyond calculated requirements—mining conditions vary as extraction progresses deeper into different geology.

Understanding fundamental operating principles helps engineers recognize why environmental stress accelerates failure. For background on arc extinction mechanisms and contact operation, see the complete guide to vacuum circuit breaker technology.

Particulate contamination in mining atmospheres typically ranges from 10–50 mg/m³, with particle sizes spanning 0.1–500 µm. Fine silica dust below 10 µm presents the greatest threat because particles penetrate standard IP54 enclosures through pressure differentials during equipment cooling cycles—the “breathing effect” created when ambient temperatures fluctuate 20°C or more between shifts.

IP Rating Requirements

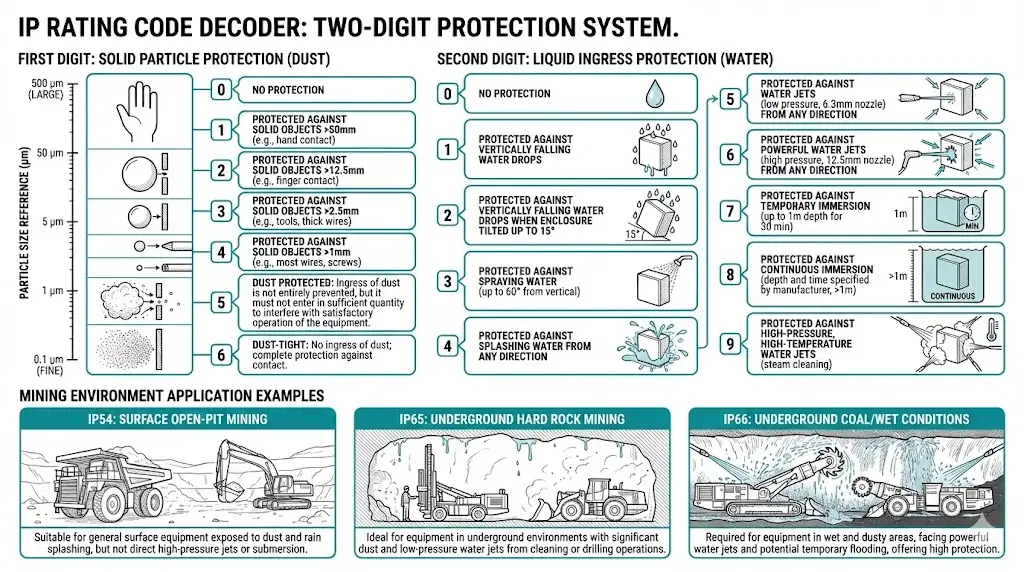

According to IEC 60529 (Degrees of protection provided by enclosures), mining switchgear requires minimum IP65 protection. The first digit (6) indicates complete dust-tight protection; the second digit (5 or 6) specifies water jet resistance.

| Mining Environment | Minimum IP | Recommended IP | Notes |

|---|---|---|---|

| Surface open-pit | IP54 | IP65 | Wind-driven mineral dust |

| Underground hard rock | IP65 | IP66 | Water mist from drilling |

| Underground coal | IP65 | IP66 | Explosive dust hazard |

| Crusher stations | IP65 | IP66 | Water-jet cleaning required |

In testing of vacuum circuit breakers in coal handling facilities, units rated below IP65 showed contact surface contamination within 18 months—compared to 8+ years for properly sealed assemblies.

Beyond IP Ratings

Creepage distance requirements increase significantly in polluted environments. Specify minimum 25 mm/kV for mining applications, compared to 16 mm/kV acceptable in clean industrial settings. Coal dust environments may warrant 31 mm/kV to provide additional margin against surface tracking.

Gasket selection matters. Silicone provides excellent temperature range and dust sealing but poor oil resistance. Neoprene offers moderate temperature tolerance with good oil resistance. EPDM delivers superior weathering resistance but fails around petroleum-based lubricants.

[Expert Insight: Dust Protection Field Observations]

- Positive-pressure enclosures with filtered intake air reduce internal dust accumulation by 80–90% compared to sealed-only designs

- Gore-Tex membrane breathers allow pressure equalization without dust entry—critical for thermal cycling environments

- Cable gland quality often determines system IP rating; specify glands rated equal to or above enclosure IP class

- Quarterly inspection of door seals identifies compression set before ingress pathways develop

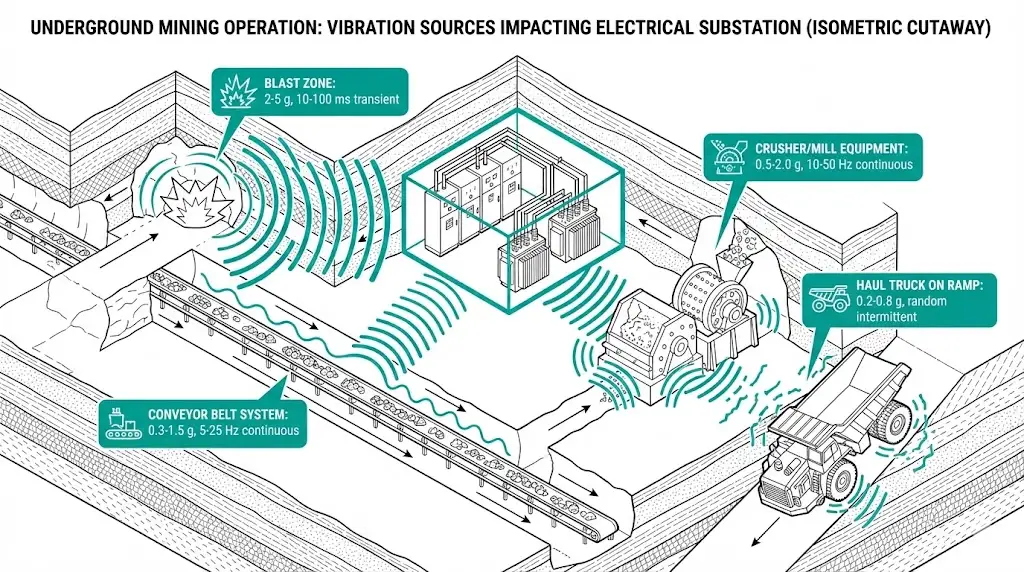

Mining operations generate vibration profiles that differ substantially from industrial manufacturing environments. Blasting events produce peak accelerations of 2–5 g lasting 10–100 milliseconds. Conveyors, crushers, and mills generate continuous vibration at 0.3–2.0 g across 10–150 Hz. Underground vehicle traffic adds random vibration spectra.

Vibration Source Characterization

| Source | Acceleration | Frequency Range | Pattern |

|---|---|---|---|

| Blasting | 2–5 g peak | Broadband impulse | Transient, 10–100 ms |

| Conveyors | 0.3–1.5 g | 5–25 Hz | Continuous |

| Crushers/mills | 0.5–2.0 g | 10–50 Hz | Continuous |

| Haul trucks | 0.2–0.8 g | 2–25 Hz | Intermittent |

Specification Parameters

IEC 62271-100 defines mechanical endurance classes. M1 provides normal mechanical endurance at 2,000 operations. M2 provides extended endurance at 10,000 operations minimum. Specify M2 for all mining applications—the additional cost is negligible compared to premature replacement.

Spring-operated mechanisms outperform magnetic actuators under shock conditions. Mechanical latching holds position during shock events, while electromagnetic holding force can be momentarily overcome by severe acceleration.

According to IEC 62271-1 (common specifications for high-voltage switchgear), vacuum circuit breakers must withstand sinusoidal vibration tests at 1 g acceleration across 2–100 Hz frequency range

Critical Verification Points

Field experience shows that standard commercial-grade mounting systems fail within 18–24 months under mining vibration profiles. Specify anti-vibration mounts rated for continuous duty at 3 g peak acceleration, with resonance frequencies below 5 Hz to decouple equipment from structural vibration sources.

The VS1 indoor vacuum circuit breaker features a robust spring-operated mechanism suitable for environments with significant mechanical stress.

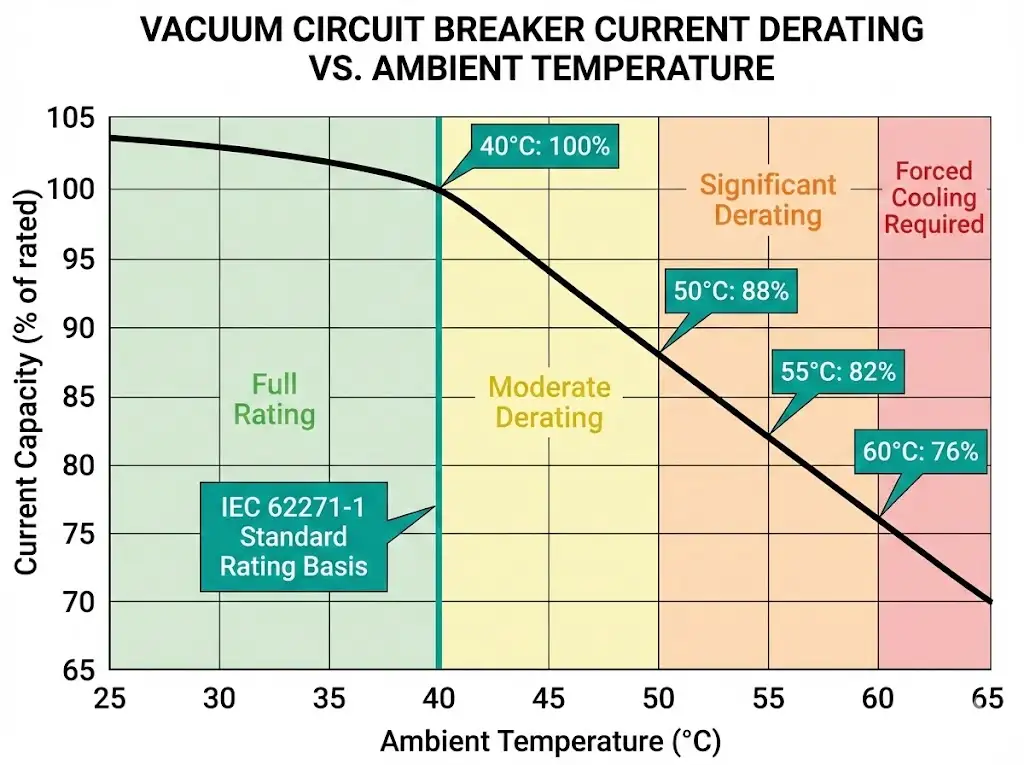

Underground mining operations at depth beyond 800 meters routinely experience ambient temperatures of 40–50°C. Virgin rock temperature increases approximately 1°C per 30–40 meters of depth. Combined with heat from transformers, drives, and limited ventilation capacity, electrical rooms operate well above the 40°C maximum ambient assumed in standard equipment ratings.

Derating Requirements

IEC 62271-1 specifies 40°C maximum ambient for rated current values. For each degree Celsius above this baseline, reduce allowable continuous current by approximately 1–1.5%.

Worked Example:

Rated current: 2,500 A at 40°C ambient

Site ambient: 52°C maximum

Temperature rise: 52°C − 40°C = 12°C

Derating factor: 12 × 1.2% = 14.4%

Effective rating: 2,500 A × 0.856 = 2,140 A

Recommendation: Specify 2,500 A breaker for 2,000 A load

Temperature Rise Limits

| Component | IEC 62271-1 Max Rise | Mining Recommendation |

|---|---|---|

| Main contacts | 50 K | 40 K |

| Bolted terminals | 70 K | 55 K |

| Accessible surfaces | 30 K | 25 K |

Thermal Cycling Effects

Surface mining in continental climates experiences daily temperature swings exceeding 35°C. These cycles accelerate elastomer aging in vacuum interrupter seals and stress solder joints through differential thermal expansion. Field assessments reveal that thermal cycling causes more rapid degradation than constant elevated temperatures.

Altitude Derating

High-altitude operations above 2,000 meters require additional derating for both dielectric strength and thermal dissipation. IEC 62271-1 specifies approximately 1% voltage derating per 100 meters above 1,000 meters elevation.

Thermal monitoring using RTD sensors on main circuit connections provides early warning of developing problems. Integration with SCADA systems enables trending analysis before failures occur.

[Expert Insight: Thermal Management Lessons from Deep Mining]

- Oversizing strategy works: specify breaker rated current at 125–150% of calculated maximum load for high-ambient installations

- Forced ventilation in switchgear rooms reduces effective ambient temperature 8–12°C in typical underground configurations

- CuCr (copper-chromium) contacts maintain stability at higher temperatures than standard copper—specify for sustained operation above 45°C ambient

- Quarterly thermographic surveys identify developing hot spots 6–12 months before failure

Material selection depends on specific environmental exposure. Stainless steel 316L provides superior corrosion resistance for acid mine drainage areas but carries significant cost and weight premium. Powder-coated mild steel—minimum 80 µm coating thickness—serves most mining applications adequately when specified with C4 or C5 corrosion protection per ISO 12944.

Aluminum offers weight advantages for mobile or relocatable substations but presents galvanic corrosion risks when in contact with steel components in wet environments. GRP (glass-reinforced polyester) provides non-conductive, corrosion-proof enclosures for surface installations but degrades under UV exposure and has limited impact resistance.

Indoor versus Outdoor Selection

Underground substations require indoor-rated equipment housed within appropriately IP-rated enclosures. Outdoor breakers lack the dust sealing necessary for underground service.

For surface mining operations requiring pole-mounted or yard installation, the ZW32 outdoor vacuum circuit breaker provides rated performance in exposed environments with enhanced weatherproofing.

Cable Entry and Termination

Cable glands must match or exceed enclosure IP rating—system protection equals the weakest penetration point. Support cables within 300 mm of entry points to prevent vibration-induced conductor fatigue at terminations. Provide mounting space and conductor routing for surge arresters in lightning-prone surface installations.

Section A: Basic Electrical Parameters

□ System voltage: _______ kV

□ Rated voltage (Ur): _______ kV

□ Rated current at 40°C: _______ A

□ Derated current at site ambient (___°C): _______ A

□ Short-circuit breaking current: _______ kA

□ Short-time withstand: _______ kA for _______ s

Section B: Environmental Protection

□ Enclosure IP rating: IP_______

□ Creepage distance: _______ mm/kV

□ Enclosure material: SS316L / powder-coated steel / aluminum

□ Gasket material: silicone / neoprene / EPDM

□ Corrosion protection: C3 / C4 / C5 per ISO 12944

Section C: Mechanical Requirements

□ Seismic withstand: _______ g

□ Mechanical endurance class: M1 / M2

□ Shock withstand: _______ g for _______ ms

□ Mounting: rigid / anti-vibration isolated

□ Operating mechanism: spring / magnetic

Section D: Thermal Requirements

□ Maximum site ambient: _______ °C

□ Minimum site ambient: _______ °C

□ Altitude (if >1000 m): _______ m

□ Cooling: natural / forced air

□ Thermal monitoring: RTD / thermocouple / none

Section E: Compliance and Documentation

□ IEC 62271-100 type test reports: required / not required

□ Seismic qualification certificate: required / not required

□ IP test certificate: required / not required

□ Mining authority approval: MSHA / DGMS / other: _______

□ Explosive atmosphere certification: Ex d / Ex e / not required

International Standards

Mining-Specific Regulations

Explosive atmosphere requirements under ATEX or IECEx may apply in coal mines or where methane concentrations exist. Verify requirements with mine ventilation engineers and safety authorities before finalizing specifications.

The IEC Technical Committee 17 develops and maintains international standards for high-voltage switchgear, including the foundational IEC 62271 series referenced throughout this checklist.

Proper mining specification requires application-specific calculations, not catalog selection. Environmental factors interact in ways that generic derating tables cannot capture.

XBRELE provides mining application support including:

Contact our engineering team for specification review and custom solutions. As a specialized vacuum circuit breaker manufacturer, XBRELE delivers equipment engineered for harsh environment installations.

Q: What IP rating do I need for underground coal mine switchgear?

A: IP65 minimum, with IP66 recommended for areas subject to water-jet cleaning or high humidity from drilling operations. Coal mines also require explosive atmosphere certification depending on methane zone classification.

Q: How much should I derate a VCB operating at 50°C ambient?

A: Reduce rated continuous current by approximately 10–15% compared to the standard 40°C rating basis. A 2,000 A breaker effectively carries 1,700–1,800 A continuous at 50°C ambient without exceeding design temperature rise limits.

Q: Is M2 mechanical endurance class necessary for mining?

A: Yes—M2 provides 10,000 operations minimum versus 2,000 for M1. Mining environments subject breakers to frequent switching and mechanical stress from vibration, making extended endurance essential for acceptable service life.

Q: Can outdoor VCBs be used directly in underground mines?

A: No. Outdoor designs lack the dust sealing required underground. Use indoor-rated equipment housed within IP65 or IP66 rated enclosures designed for the specific mine environment.

Q: What creepage distance should I specify for dusty conditions?

A: Minimum 25 mm/kV for heavily polluted mining environments, compared to 16 mm/kV acceptable in clean industrial settings. Coal dust or conductive particulate areas may warrant 31 mm/kV.

Q: How does altitude affect VCB specification above 2,000 meters?

A: Reduced air density decreases both dielectric strength and cooling capacity. Apply voltage derating of approximately 1% per 100 m above 1,000 m elevation, plus additional current derating for reduced heat dissipation at extreme altitude.

Q: How often should terminal torque be verified in mining installations?

A: Every 6–12 months in high-vibration locations near crushers or conveyors, compared to 24-month intervals acceptable in stable industrial installations. Vibration causes micro-fretting at connection points that loosens terminals over time.