Need Full Specifications?

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

Selection Matrix: Based on our technical benchmarking, brand selection should be determined by the specific application criticality and TCO (Total Cost of Ownership) requirements:

Technical Verdict: For standard industrial applications (Mining, Pumps, Conveyors), XBRELE delivers the highest ROI, matching the electrical endurance of Tier 1 brands without the associated brand premium.

Looking for the Best Vacuum Contactor Brands of 2025? We benchmark ABB, Eaton, Schneider, and XBRELE on performance, endurance, and price. Read this expert guide before you spec your next MCC.

Let’s be honest: nobody notices a vacuum contactor until it fails. But when a main switching unit goes down in a mining hoist, a kiln fan, or a water treatment pump, the downtime costs accrue by the minute.

In 2025, the industrial landscape has shifted. The market for vacuum contactors is no longer just about buying the most famous logo. It has split into two distinct camps. On one side, you have the legacy giants—ABB, Eaton, and Schneider Electric—pushing high-tech, digitally connected solutions. On the other, specialized manufacturers like XBRELE are disrupting the market with a “factory-direct” approach, offering compatible industrial performance without the massive markup.

For engineers and procurement managers, this creates a dilemma. Do you pay a premium for IoT features you might never use? Or do you trust a challenger brand? This guide isn’t just a list of specs; it’s a pragmatic look at reliability, maintenance realities, and Total Cost of Ownership (TCO) to help you make the right call for your BOM (Bill of Materials).

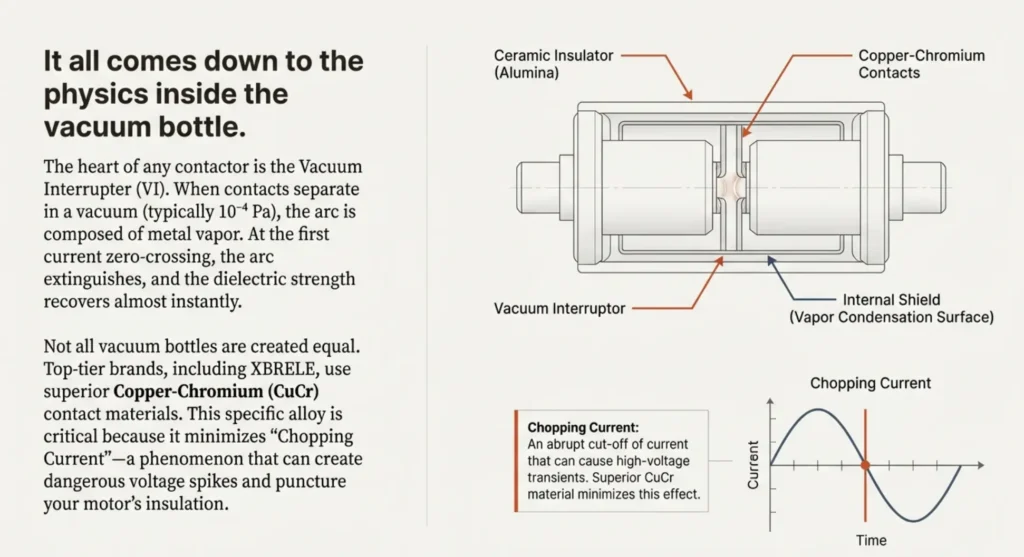

To choose the right brand, you have to understand the physics of the failure point. The heart of any contactor is the Vacuum Interrupter (VI).

Unlike air-break contactors that rely on arc chutes and magnetic blowouts to stretch and cool the arc, vacuum contactors operate on a different principle: dielectric recovery. When the contacts separate under load in a vacuum (typically $10^{-4}$ Pa), the arc is composed entirely of metal vapor from the contacts themselves. Because there is no gas to sustain the plasma, this metal vapor expands rapidly and condenses on the internal shields.

At the very first current zero-crossing (in AC circuits), the arc is extinguished, and the dielectric strength across the gap recovers almost instantly.

Why does this matter for your brand choice?

Not all vacuum bottles are created equal. Top-tier brands (including XBRELE) use superior Copper-Chromium (CuCr) contact materials. This specific alloy is critical because it minimizes “Chopping Current”—a phenomenon where the arc is cut off too abruptly, creating dangerous voltage spikes that can puncture your motor’s insulation.

Technical Deep Dive: Want to understand the physics of arc extinction in detail? Read our engineering breakdown: How Does a Vacuum Contactor Extinguish Arc? Inside the Vacuum Interrupter.

Marketing brochures are often optimistic. As engineers, we look at three harder metrics to determine real-world value.

Most datasheets shout about AC-3 life (starting squirrel-cage motors). That’s the “easy” test. The real stress test is AC-4 duty—inching, plugging, and reversing motors.

This measures the lifespan of the solenoid, springs, and latching mechanism. If the mechanical latch wears out, the contacts will start to “bounce” upon closing. Contact bounce is the silent killer of vacuum interrupters, leading to micro-welds and eventual phase loss.

While a contactor isn’t a circuit breaker, it must be able to withstand the “let-through” energy of a short circuit until the fuse or breaker trips. This is known as Type 2 Coordination.

ABB is widely considered the heavyweight champion of the sector, particularly for Medium Voltage (MV) applications.

Key Technology: Solid Embedded Poles

ABB’s V-Contact series often utilizes embedded pole technology. Instead of leaving the vacuum bottle exposed, they cast it directly into a block of epoxy resin or thermoplastic. This makes the unit virtually impervious to dust, humidity, and vibration.

Pros:

Cons:

Verdict: If budget is no object and failure could cause an environmental disaster, buy ABB.

Eaton (carrying the legacy of Westinghouse and Cutler-Hammer) builds contactors that are famously robust and compact, favoring NEMA-style ruggedness.

Key Technology: Compact Footprint

Eaton focuses on power density. Their vacuum contactors are often smaller than European competitors, making them perfect for retrofitting into crowded, existing Motor Control Centers (MCCs) where space is tight.

Pros:

Cons:

Verdict: The go-to choice for commercial buildings, HVAC, and standard industrial panels in North America.

If your facility is moving toward Industry 4.0, Schneider Electric’s TeSys range is likely on your radar.

Key Technology: EcoStruxure Integration

Schneider views the contactor not just as a switch, but as a data node. Their high-end models can communicate wear data, coil temperature, and cycle counts directly to the cloud / SCADA system via Modbus or Ethernet.

Pros:

Cons:

Verdict: Ideal for automated data centers or highly integrated process lines requiring 99.999% uptime visibility.

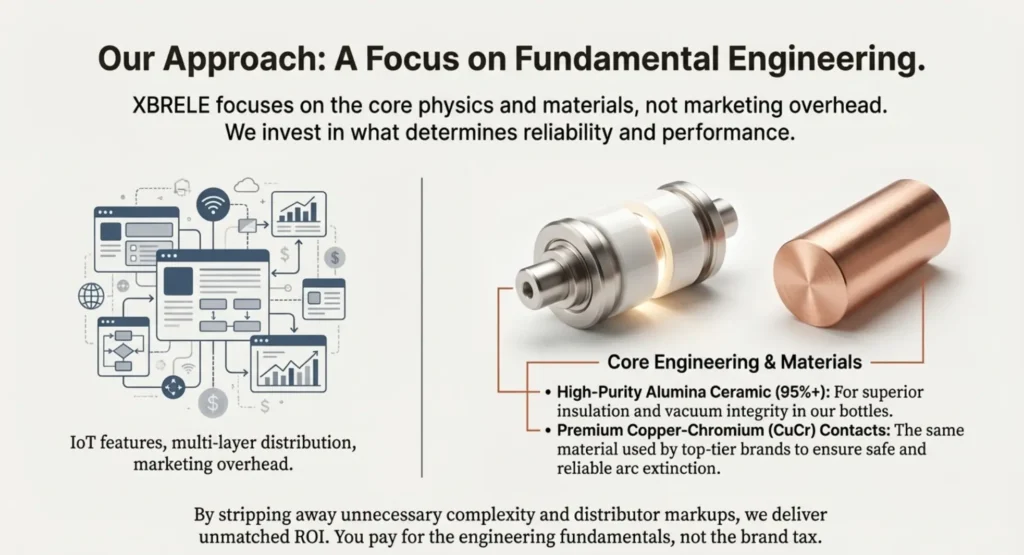

XBRELE represents a shift in the 2025 market: The rise of the “High-Quality Alternative.” XBRELE has gained traction by strictly adhering to IEC standards while stripping away the marketing overhead.

Key Technology: Fundamental Engineering

XBRELE focuses on the core physics. We use high-purity (95%+) Alumina ceramic for our vacuum bottles and premium Copper-Chromium contacts—the exact same materials used by the top tier.

Pros:

Cons:

Verdict: The smartest choice for OEM switchgear manufacturers, retrofits, and projects where budget matters but performance cannot be compromised.

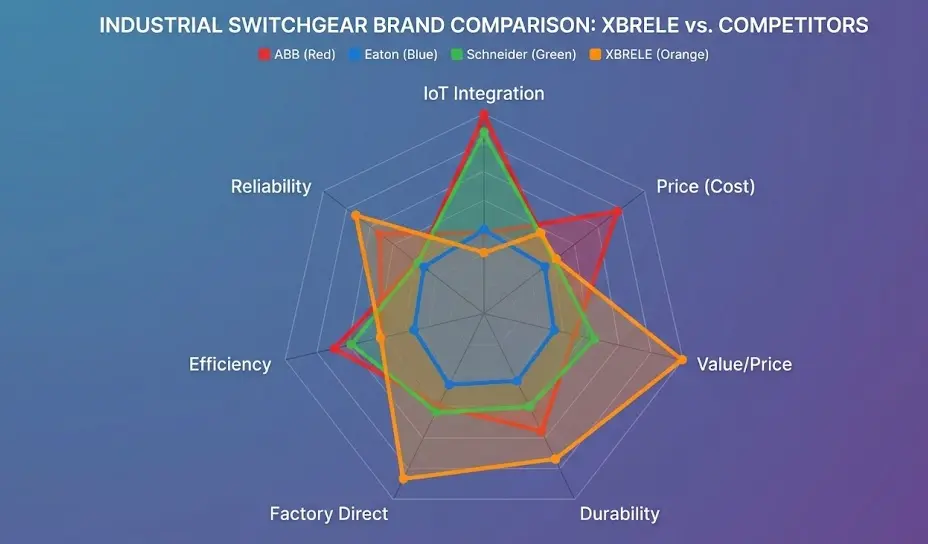

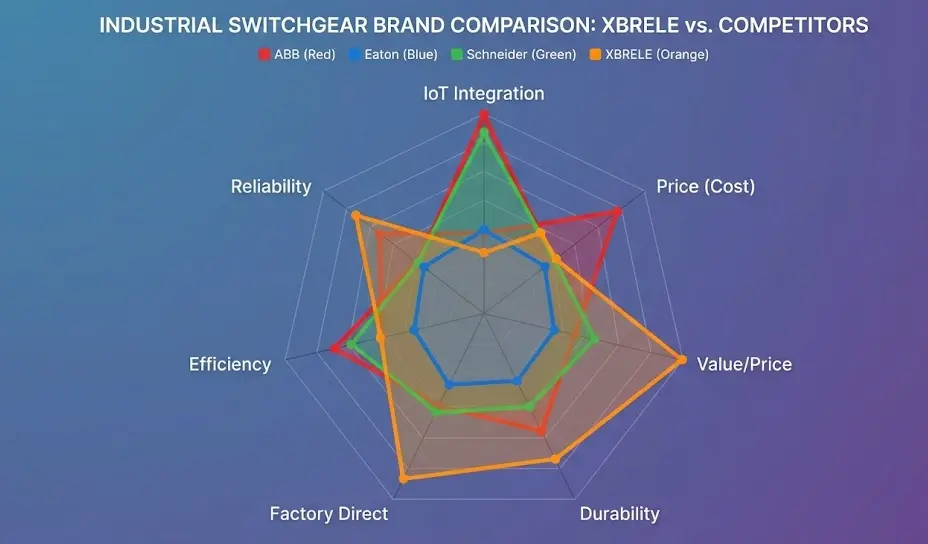

To help you visualize the trade-offs, we have scored these brands based on 2025 market data.

| Criteria | ABB | Eaton | Schneider | XBRELE | Analysis |

| Extreme Env. Reliability | ⭐⭐⭐⭐⭐ | ⭐⭐⭐⭐ | ⭐⭐⭐⭐⭐ | ⭐⭐⭐⭐ | ABB wins for salt-spray/nuclear; XBRELE is robust for mining/industrial. |

| IoT & Connectivity | ⭐⭐⭐⭐ | ⭐⭐⭐ | ⭐⭐⭐⭐⭐ | ⭐⭐ | Schneider dominates smart tech. XBRELE focuses on hard-wired reliability. |

| Price (Low is good) | ⭐ | ⭐⭐⭐ | ⭐⭐ | ⭐⭐⭐⭐⭐ | XBRELE is the undisputed leader in affordability. |

| Overall Value | ⭐⭐⭐ | ⭐⭐⭐⭐⭐ | ⭐⭐⭐ | ⭐⭐⭐⭐⭐ | Eaton and XBRELE offer the best “bang for buck.” |

| Customization | ⭐⭐ | ⭐⭐⭐ | ⭐⭐ | ⭐⭐⭐⭐⭐ | XBRELE offers OEM-specific tweaks that giants won’t do. |

Regardless of whether you buy an ABB unit or an XBRELE one, 80% of failures happen due to poor installation or lack of maintenance, not the manufacturing quality.

The “Top 3” Killers of Vacuum Contactors:

[⚠️ IMAGE INSERTION POINT 4: Torque/Installation Warning Diagram]

Expert Guide: Don’t let a $500 installation error ruin a $50,000 panel. Read our step-by-step guide on How to Install a Vacuum Contactor Properly (With Wiring Examples).

Already facing issues? Troubleshoot with our Top 10 Vacuum Contactor Failure Causes Guide.

One area where confusion often arises is standards. International brands usually push IEC (International Electrotechnical Commission) standards, while in some Asian markets, GB standards prevail.

For vacuum contactors, the key standards are IEC 60947-4-1 (Low Voltage) and IEC 62271-106 (High Voltage). It is crucial to understand that simply “meeting” a standard isn’t enough; the device must be type-tested for your specific altitude and environmental conditions.

Read More: We break down the differences and why they matter for your project in our article: IEC vs GB Standards for Vacuum Contactors: The Ultimate Engineering Guide.

Here are the most common questions our engineering team receives regarding brand selection and application:

Q1: What makes vacuum contactors better than traditional air-break contactors?

A: Efficiency and Safety. Vacuum contactors extinguish arcs in a sealed environment, meaning no ionized gas escapes. This allows for a much compact design, longer electrical life (often 10x that of air types), and zero risk of external fire from arcing.

See the safety data in our article: Vacuum vs Air Contactor: Boosts Mining Safety Fast.

Q2: Which brand has the best smart connectivity?

A: Schneider Electric is the clear winner here. If you need native integration with a PLC or SCADA system for predictive maintenance data, their TeSys series is unmatched.

Q3: Are ABB vacuum contactors really worth the high price?

A: It depends on the application. For Mission Critical applications (like nuclear power, sub-sea, or explosive environments), Yes—the price includes rigorous testing and global certification. for standard industrial use, you are often paying for the “brand tax.”

Q4: Is XBRELE reliable enough for heavy industry?

A: Absolutely. For standard and heavy-duty industrial use cases (mining, manufacturing, renewables), XBRELE offers IEC-compliant reliability. The main trade-off is that our global support network is smaller than ABB’s, which is why we offer such a significant price advantage.

Q5: Can Eaton contactors integrate with industrial controls?

A: Yes, but their integration is generally more “traditional” (using auxiliary contacts) compared to Schneider’s digital-native approach.

Q6: How often should vacuum contactors be maintained?

A: We recommend an annual inspection. While the vacuum bottle itself is maintenance-free, you must check the contact wear indicator, tighten terminals, and clean the insulation framework. Frequency increases for harsh environments.

Download our checklist: Essential Steps for Transformer & Contactor Maintenance.

As we look beyond 2025, the market is heading toward “Democratized Quality.”

The technology of vacuum interruption is maturing. What used to be “rocket science” exclusive to top-tier brands is now accessible via brands like XBRELE.

Expect to see:

The “best” brand is purely contextual:

Ready to upgrade your motor control strategy?

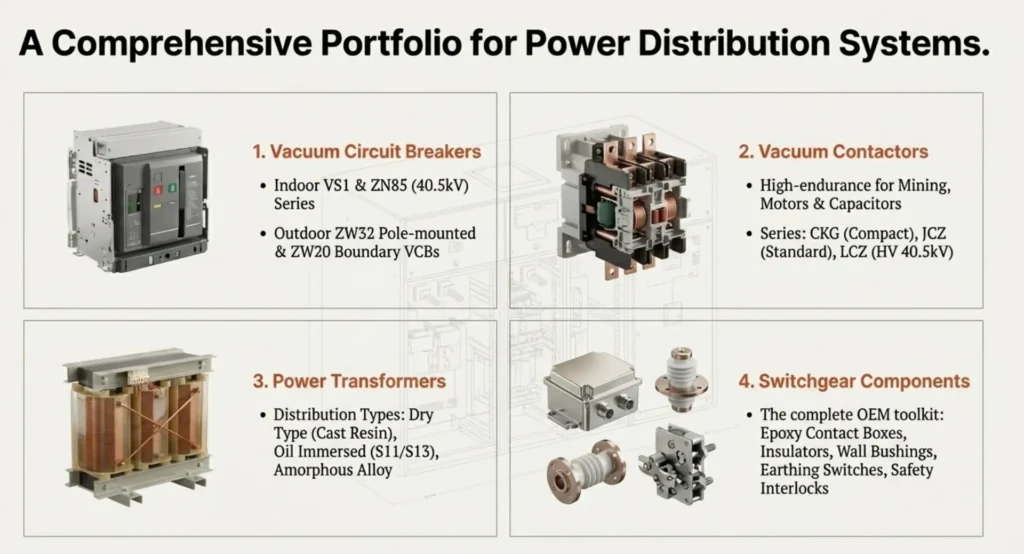

Don’t let legacy habits dictate your budget. Explore our full range of Vacuum Contactors and Vacuum Circuit Breakers.

Whether you need a single replacement unit or an OEM partner for 1,000 units, Contact XBRELE Engineering Team today for a technical consultation and quote.

Make an informed decision for your next project. This strategic analysis compares technical specifications, insulation technology, maintenance duty cycles, and global lead times for MV switchgear and circuit breakers.

Download Comparison Analysis