Benötigen Sie die vollständigen Spezifikationen?

Laden Sie unseren Produktkatalog 2025 herunter, um detaillierte Zeichnungen und technische Parameter aller Schaltanlagenkomponenten zu erhalten.

Katalog anfordern

Laden Sie unseren Produktkatalog 2025 herunter, um detaillierte Zeichnungen und technische Parameter aller Schaltanlagenkomponenten zu erhalten.

Katalog anfordern

Laden Sie unseren Produktkatalog 2025 herunter, um detaillierte Zeichnungen und technische Parameter aller Schaltanlagenkomponenten zu erhalten.

Katalog anfordern

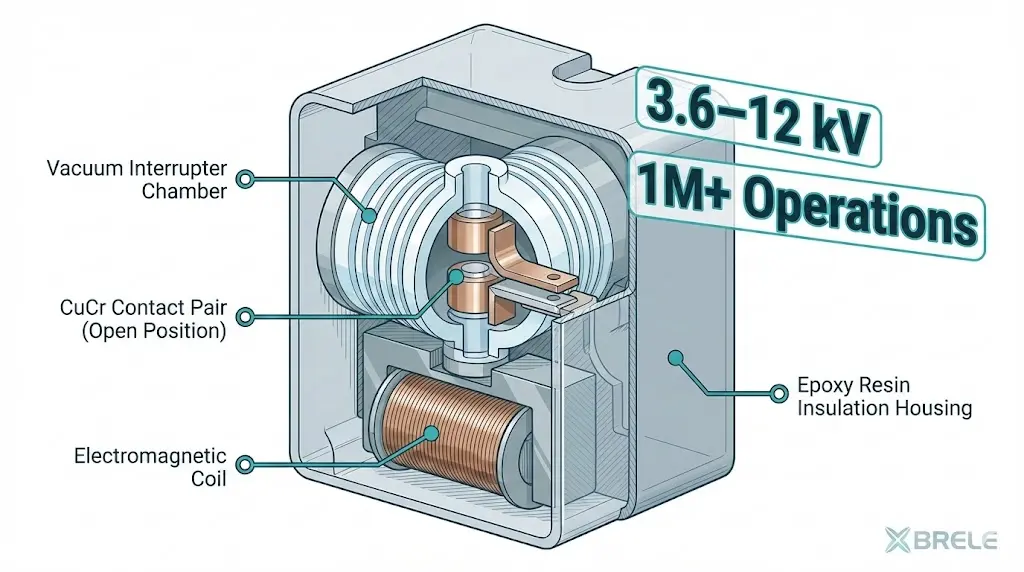

Ein Vakuumschütz ist ein elektromagnetisches Mittelspannungs-Schaltgerät, das Stromkreise unter Last mit Hilfe der Vakuumunterbrechertechnologie schaltet und unterbricht. Durch den Betrieb in abgedichteten Kammern, in denen der Druck unter 10-³ Pa bleibt, erreichen diese Geräte eine überragende Lichtbogenlöschleistung und eine längere Lebensdauer, die Luft- oder Ölschütze einfach nicht erreichen können.

Im Bereich von 1 kV bis 12 kV sind Vakuumschütze die bevorzugte Lösung für sich wiederholende Schaltanwendungen. Das Gerät kombiniert mechanische Einfachheit mit der Effizienz der Vakuumlichtbogenlöschung und unterscheidet sich damit grundlegend von Luftschützen und Vakuumleistungsschaltern. Die Kenntnis dieses Unterschieds verhindert kostspielige Fehlanwendungen in Motorsteuerungszentren, Kondensatorbatterien und Transformatorabgängen.

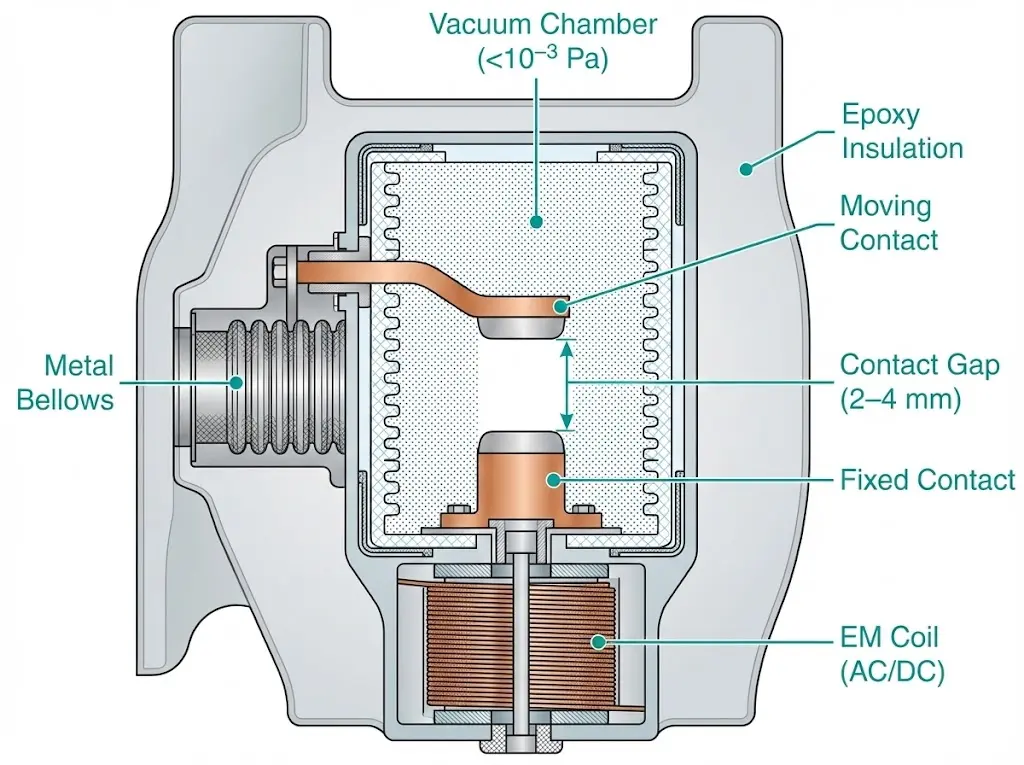

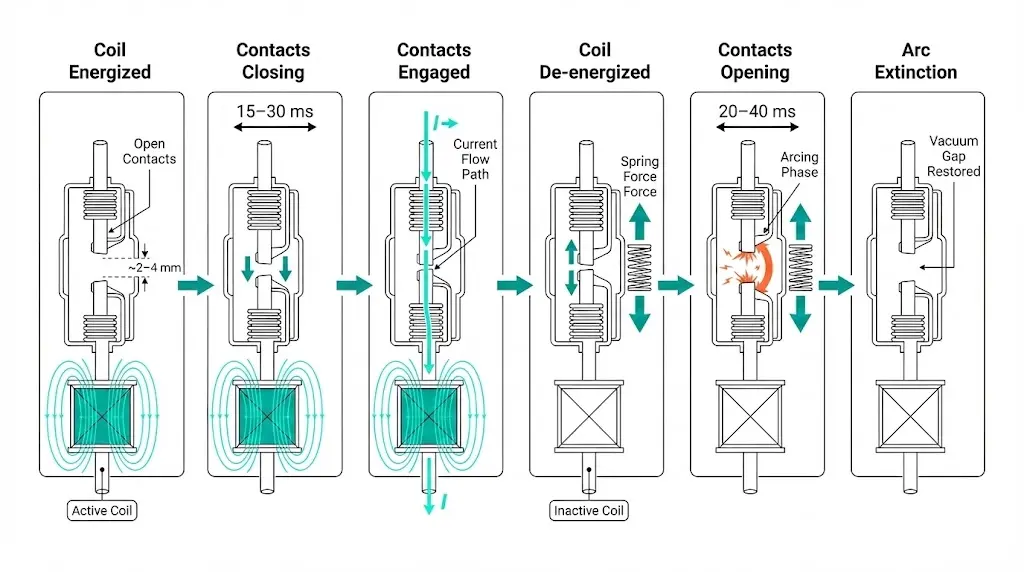

Das Vakuumschütz funktioniert nach einem einfachen elektromagnetischen Prinzip. Wenn die Steuerspule unter Spannung steht, erzeugt sie ein Magnetfeld, das die bewegliche Kontaktbaugruppe zu den festen Kontakten zieht und den Stromkreis schließt. Der entscheidende Unterschied zu anderen Schalttechnologien liegt in dem, was bei der Kontakttrennung passiert: Der entstehende Lichtbogen erlischt schnell, da Metalldampf in der Vakuumumgebung keine Ionisierung aufrechterhalten kann.

Die Durchschlagfestigkeit in der Vakuumkammer erreicht etwa 40 kV/mm - etwa viermal höher als bei atmosphärischer Luft. Dies ermöglicht Kontaktabstände von nur 2-4 mm für 7,2 kV-Anwendungen und damit kompakte Konstruktionen mit geringerem Energiebedarf.

Gemäß IEC 62271-106 (Wechselstromschütze, schützbasierte Steuerungen und Motorstarter) müssen Vakuumschütze eine mechanische Lebensdauer von mehr als 1 Million Schaltspielen und eine elektrische Lebensdauer von mindestens 500.000 Schaltspielen bei Nennstrom aufweisen. Diese Werte liegen deutlich über denen von ölgefüllten oder luftgefüllten Alternativen, die in der Regel 50.000-100.000 elektrische Schaltspiele erreichen.

Felddaten von Motorsteuerungszentralen in Bergbaubetrieben zeigen, dass Vakuumschütze unter identischen Schaltbedingungen 80% niedrigere Kontaktabbrandraten als SF₆-Alternativen erreichen. Die versiegelte Konstruktion beseitigt auch Bedenken hinsichtlich der Umweltverschmutzung - ein Faktor, der aufgrund moderner Umweltvorschriften immer wichtiger wird.

[Experteneinblick: Leistungsbeobachtungen vor Ort]

- Vakuumschütze in Motorsteuerungszentralen im Bergbau übersteigen routinemäßig 2 Millionen elektrische Schaltungen bei Nennstrom - das ist das Vierfache der Lebensdauer von gleichwertigen Luftschützkonstruktionen.

- Messungen der Kontakterosion bei mehr als 200 Installationen zeigen 0,05-0,1 mm Materialverlust pro 100.000 Betätigungen im AC-3-Betrieb

- Durch die versiegelte Vakuumkonstruktion entfallen die monatlichen Reinigungsintervalle, die für Freiluftschütze in staubigen Umgebungen erforderlich sind

Wenn es unter Last zur Kontakttrennung kommt, schafft die Vakuumschaltröhre die Voraussetzungen für ein schnelles Erlöschen des Lichtbogens. Das nahezu perfekte Vakuum (Druck unter 10-³ Pa) sorgt dafür, dass der Metalldampf aus den CuCr-Kontakten sofort diffundiert, anstatt die Ionisierung aufrechtzuerhalten. Die Lichtbogendauer beträgt in der Regel nur 8-15 Millisekunden, bevor der Strom auf natürliche Weise den Nullpunkt erreicht.

Bei Stromausfall erlangt der Vakuumspalt innerhalb von Mikrosekunden seine Durchschlagsfestigkeit zurück. Diese Wiederherstellungsgeschwindigkeit - etwa 20-30 kV/mm Wiederherstellung innerhalb von 10-20 μs - verhindert Wiedereinschaltphänomene, die Kondensatorbatterien beschädigen und eine Spannungserhöhung in herkömmlichen Schaltgeräten verursachen.

Der elektromagnetische Betätigungsmechanismus unterscheidet sich grundlegend von Leistungsschaltern. Während bei Leistungsschaltern federbelastete Mechanismen verwendet werden, die eine manuelle oder motorische Wicklung erfordern, werden bei Vakuumschützen AC- oder DC-Elektromagnete für den direkten Betrieb eingesetzt. Typische Einschaltzeiten liegen bei 15-30 ms, die Öffnungszeit bei 20-40 ms.

Die elektromagnetische Spule arbeitet mit Steuerspannungen von 24 V DC bis 230 V AC und verbraucht beim Schließen 30-80 VA und beim Halten nur 5-15 VA. Diese niedrige Halteleistung ermöglicht einen häufigen Betrieb ohne übermäßige Wärmeentwicklung - ein kritischer Faktor, wenn die Schalthäufigkeit 1.200 Schaltungen pro Stunde erreicht.

Die Federrückstellung sorgt für eine ausfallsichere Öffnung, wenn die Spule stromlos wird. Es gibt keinen Mechanismus mit gespeicherter Energie, der gewartet oder überprüft werden muss. Diese Einfachheit schlägt sich direkt in der Zuverlässigkeit nieder.

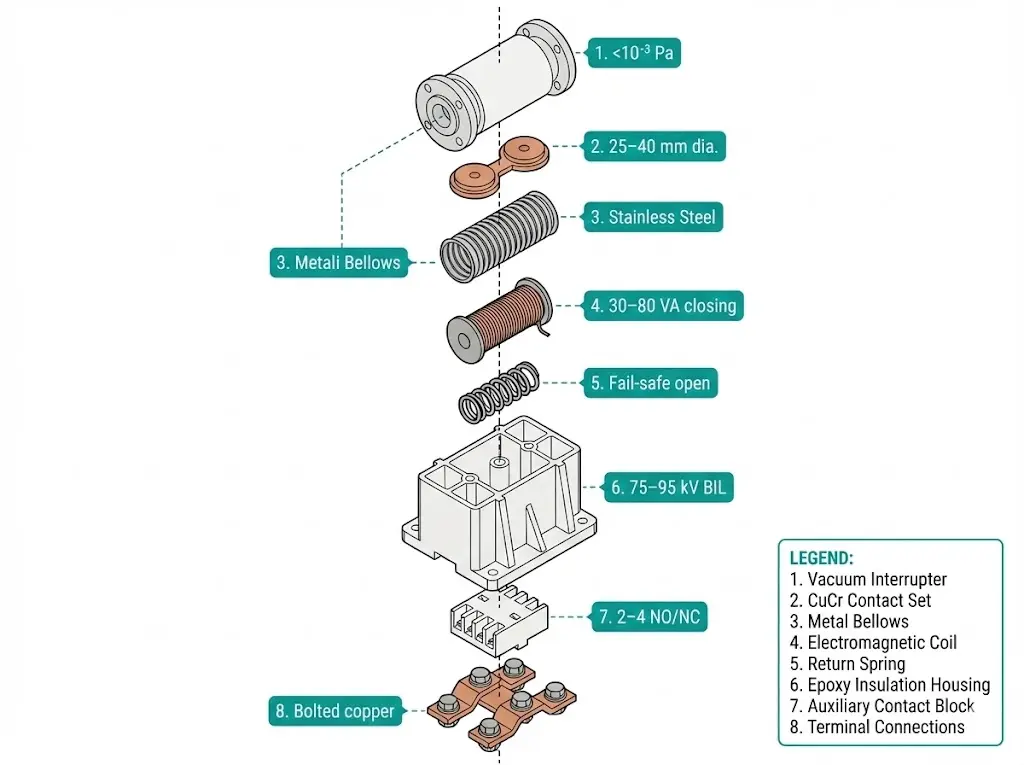

Fünf primäre Untersysteme arbeiten koordiniert: die Vakuumschaltröhre, der elektromagnetische Betätigungsmechanismus, die Isolationsstruktur, die Hilfskontakte und die Klemmenanschlüsse.

Die Vakuumschaltröhre dient als Kernschaltelement, in dem die Lichtbogenlöschung stattfindet. Jeder Unterbrecher enthält Kontakte aus einer CuCr-Legierung (Kupfer-Chrom), die je nach Nennstrom typischerweise einen Durchmesser von 25-40 mm haben. Der Kontaktabstand liegt zwischen 3 und 6 mm für Schütze mit einer Nennspannung von bis zu 12 kV und ist damit deutlich kleiner als bei Vakuum-Leistungsschaltern, die 8 bis 12 mm Abstand für die Fehlerunterbrechung benötigen.

Die Umhüllung aus Keramik oder Glas bietet sowohl mechanischen Halt als auch die Möglichkeit der Sichtprüfung. Metallbälge ermöglichen eine axiale Kontaktbewegung, während die hermetische Abdichtung erhalten bleibt, die für eine 20-jährige Vakuumintegrität unerlässlich ist.

Die Epoxidharzkapselung sorgt für eine Phase-Phase- und Phase-Erde-Isolierung, die für BIL-Werte (Basic Insulation Level) von 75-95 kV bei der 7,2 kV-Klasse ausgelegt ist. Die kompakte Isolationsstruktur trägt zum Platzvorteil des Schützes gegenüber ölgefüllten Alternativen bei.

Hilfskontakte - in der Regel 2-4 Schließer/Öffner-Kombinationen - ermöglichen die Verriegelung von Steuerkreisen und die Statusanzeige. Diese Kontakte führen nur Ströme auf Signalebene, müssen aber mit der Zeitsteuerung des Hauptkontakts koordiniert werden.

| Komponente | Funktion | Typische Spezifikation |

|---|---|---|

| Vakuumunterbrecher | Lichtbogen-Löschkammer | <10-³ Pa Innendruck |

| CuCr Kontakte | Stromtragfähigkeit, Lichtbogenfestigkeit | 25-40 mm Durchmesser |

| Metallbälge | Hermetische Dichtung mit Axialbewegung | Rostfreier Stahl, geschweißt |

| Elektromagnetische Spule | Erzeugung von Schließkraft | 30-80 VA schließen, 5-15 VA halten |

| Epoxid-Gehäuse | Phasenisolierung | 75-95 kV BIL bei 7,2 kV Klasse |

| Hilfskontakte | Schnittstelle zum Steuerkreis | 2-4 NO/NC-Kombinationen |

Die Hauptaufgabe eines Vakuumschützes besteht in der Steuerung des Laststroms unter normalen Betriebsbedingungen. Drei Hauptfunktionen dominieren die industriellen Anwendungen:

Starten und Stoppen des Motors - Ein- und Ausschalten von Asynchronmotoren mit einer Leistung von typischerweise 200 kW bis 5.000 kW bei 3,3 kV-12 kV. Die Einschaltströme erreichen beim Start das 6-8-fache des Nennstroms.

Umschaltung der Kondensatorbank - Ein- und Ausschalten von Blindleistungskompensationsanlagen mit Einschaltströmen bis zum 20-fachen des Nennwertes. Gegenläufige Schaltszenarien erzeugen Spitzenströme von bis zu 20 kA bei Frequenzen von annähernd 4.000 Hz.

Einschalten des Transformators - Schalten der Primärseite von Mittelspannungstransformatoren im Leerlauf, wo der Einschaltmagnetisierungsstrom das 8-12fache des Nennstroms erreichen kann.

Gemäß IEC 60947-4-1 (Schütze und Motorstarter) müssen Vakuumschütze eine mechanische Belastbarkeit von ≥1 × 106 Operationen und eine elektrische Ausdauer von ≥3 × 105 Schaltspiele bei AC-3-Betrieb (Motorstart). Diese Anforderungen gehen weit über die Spezifikationen von Leistungsschaltern hinaus, die in der Regel nur 2.000-10.000 mechanische Betätigungen vorschreiben.

| Pflichtenkategorie | Anwendung | Aktuell machen | Aktuelle Nachrichten |

|---|---|---|---|

| AC-3 | Motorstart, laufende Last | Bis zu 6× Ie | ≤ Ie |

| AC-4 | Motor Tippen, Stecken, Reversieren | Bis zu 6× Ie | Bis zu 6× Ie |

| AC-6a | Transformator-Schalten | Bis zu 12× Ie Einschaltdauer | Leerlauf/Leichtlast |

| AC-6b | Umschaltung der Kondensatorbank | Hoher Einschaltstrom | Kapazitiver Strom |

Tests in Bergbauanwendungen mit häufigen Lastwechseln ergaben, dass Vakuumschütze Schließzeiten von 30-50 ms und Öffnungszeiten von 25-40 ms erreichen. Diese Geschwindigkeit bietet Koordinationsvorteile in Motorschutzsystemen und minimiert gleichzeitig die Kontakterosion bei Einschaltstromereignissen.

XBRELE's Vakuumschütze der Serie JCZ sind speziell für AC-3- und AC-4-Motorschaltaufgaben in anspruchsvollen industriellen Umgebungen konzipiert.

[Experteneinblick: Schaltleistung von Kondensatoren]

- Dielektrische Wiederherstellung des Vakuumschaltgeräts stellt innerhalb von 10-20 μs nach Stromausfall die volle Stärke wieder her - ein kritischer Faktor zur Vermeidung von Kondensatorrückschlägen

- Back-to-Back-Kondensatorinstallationen erfordern Vorschaltwiderstände, wenn der Spitzenstromstoß die Schützeinschaltkapazität übersteigt

- Die Kontaktlebensdauer im AC-6b-Betrieb erreicht typischerweise 100.000 Schaltspiele gegenüber mehr als 300.000 Schaltspielen im AC-3-Betrieb aufgrund der höheren transienten Belastung.

Die Unterscheidung zwischen Vakuumschützen und Vakuum-Leistungsschalter geht es um eine grundlegende Frage: Wer ist für den Fehlerstrom zuständig?

Vakuumschütze können Nennströme bis zu 400-800 A mit begrenzter Fehlerstrombelastbarkeit bewältigen und erfordern im Allgemeinen vorgeschaltete Schutzeinrichtungen zur Fehlerbeseitigung. Die typische Kurzschlussfestigkeit beträgt 25 kA für 1 Sekunde - das Schütz überlebt den Fehler, unterbricht ihn aber nicht.

Vakuum-Leistungsschalter hingegen sind für eine Kurzschlussunterbrechung von 25-50 kA ausgelegt und verfügen über integrierte Schutzrelais, die Fehler selbstständig erkennen und löschen.

| Parameter | Vakuumschütz | Vakuum-Leistungsschalter |

|---|---|---|

| Primäre Funktion | Häufige Lastwechsel | Störungsunterbrechung + Lastschaltung |

| Kurzschlussunterbrechung | 2-5 kA (Absicherung erforderlich) | 25-50 kA (freistehend) |

| Mechanische Lebensdauer | 500.000-1.000.000+ Operationen | 10.000-30.000 Operationen |

| Elektrische Lebensdauer | 300.000+ bei Ie | 50-100 bei der Fehlerbewertung |

| Schutzrelais | Extern (separates Gerät) | Integral |

| Koordinierung der Sicherungen | Erforderlich | Nicht erforderlich |

| Kontakt Gap | 3-6 mm | 8-12 mm |

Der Kostenunterschied spiegelt diese Leistungsunterschiede wider. Ein Vakuumschütz kostet deutlich weniger als ein Leistungsschalter, erfordert aber eine koordinierte H-Sicherung für den Fehlerschutz. In Motorsteuerungszentralen bleibt die Schütz-Sicherungs-Kombination wirtschaftlich, wenn die Schalthäufigkeit den Aufpreis für die Ausdauer rechtfertigt.

Auswahlhilfe: Spezifizieren Sie Schütz-Sicherungs-Kombinationen für Anwendungen zum Schalten von Lasten mit hoher Taktzahl. Spezifizieren Sie Vakuum-Leistungsschalter, wenn das Gerät selbstständig Fehlerströme ohne vorgelagerte Koordination löschen muss.

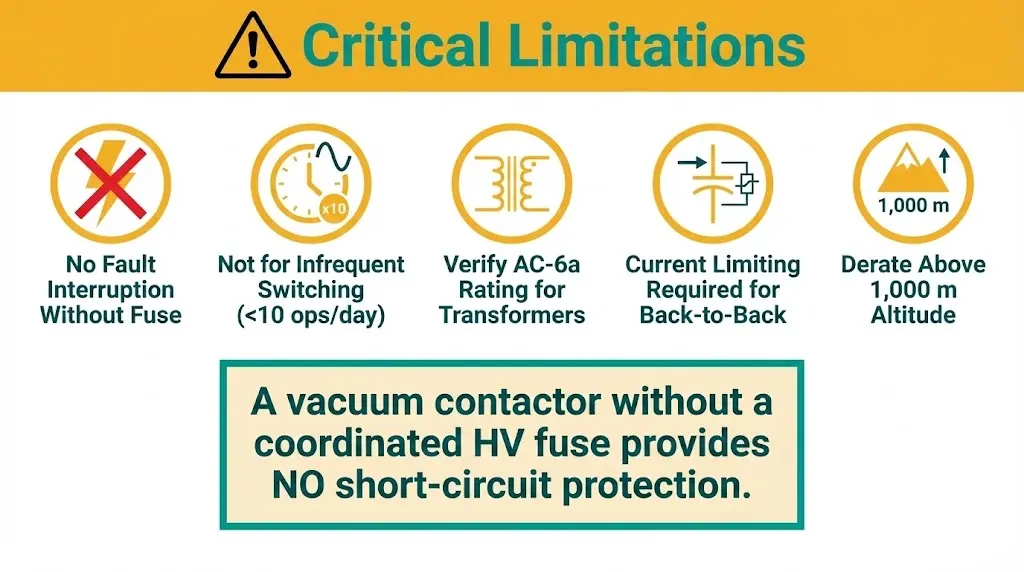

Das Wissen um die Grenzen verhindert teure Ausfälle. Vakuumschütze eignen sich hervorragend für bestimmte Anwendungen - eine falsche Anwendung hat jedoch schwerwiegende Folgen.

Ein Vakuumschütz ist KEINE Schutzeinrichtung. Die Unterbrechungskapazität reicht normalerweise nur von 2-5 kA. Der Versuch, einen 25 kA-Fehler ohne vorgeschalteten Sicherungsschutz zu unterbrechen, führt zur Zerstörung des Schützes, zu einem möglichen Lichtbogen und zu längeren Ausfallzeiten.

Jeder Vakuumschütz-Installation muss eine koordinierte Hochspannungs-HV-Sicherung vorgeschaltet werden. Die Sicherung ist für Fehlerströme zuständig, das Schütz für das Schalten der Last. Eine Verwechslung dieser Aufgaben birgt Gefahren.

Wenn die Schalthäufigkeit unter 5-10 Schaltspiele pro Tag fällt, ist die hohe Lebensdauer des Schützes nicht mehr gegeben. Ein Lasttrennschalter oder Leistungsschalter kann sich bei seltenen Schaltaufgaben als kostengünstiger erweisen. Der Wertbeitrag des Vakuumschützes hängt vom häufigen Betrieb ab.

Der Einschaltstrom des Transformators erreicht das 8-12fache des Nennstroms. Nur Schütze, die ausdrücklich für den AC-6a-Betrieb ausgelegt sind, sollten die Primärseite von Transformatoren einschalten. Die Verwendung eines AC-3-Schützes zum Schalten von Transformatoren führt zu übermäßigem Kontaktabbrand und möglichem Verschweißen. Überprüfen Sie vor der Anwendung die Spezifikationen des Herstellers.

Die gegenseitige Einschaltung von Kondensatorbatterien erzeugt extreme Einschaltspitzenströme von bis zu 20 kA bei Frequenzen von annähernd 4.000 Hz. Ohne Vorschaltwiderstände oder strombegrenzende Drosseln treten diese Ströme bei Schützen auf:

Das Vakuumschütze der Baureihe CKG enthalten Vorkehrungen für Kondensatorschaltanwendungen, aber die Strombegrenzung auf Systemebene bleibt für Back-to-Back-Konfigurationen unerlässlich.

Über 1.000 m Höhe nimmt die Stärke der Außenluftisolierung ab. Die Kriechstrecken können eine Leistungsreduzierung oder erweiterte Isoliererkonstruktionen erfordern. Salzsprühnebel an der Küste und industrielle Verunreinigungen - Zementstaub, Metallpartikel, korrosive Gase - übersteigen die Isolierfähigkeit von Standardschützen. Für raue Umgebungen sind geschlossene oder versiegelte Ausführungen zu wählen.

Vakuumschütze zeigen eine außergewöhnliche Leistung in Umgebungen, die häufige Schaltvorgänge erfordern - sie übertreffen regelmäßig 1 Million mechanische Schaltvorgänge während ihrer Lebensdauer.

Im Bergbau werden Hochleistungsmotoren mit einer Leistung von 200 kW bis 3.000 kW bei Spannungen zwischen 3,3 kV und 7,2 kV betrieben. Förderbandsysteme und Brecheranlagen erfordern 30-50 Start-Stopp-Zyklen pro Stunde. Die Vakuumschaltröhre bewältigt Einschaltströme ohne nennenswerten Kontaktabbrand.

Die Kontaktlebensdauer in Mineralienaufbereitungsanlagen übersteigt in der Regel 2 Millionen elektrische Schaltspiele bei Nennstrom - das Vierfache der Lebensdauer gleichwertiger Luftunterbrecher-Konstruktionen. Diese Langlebigkeit senkt direkt die Wartungskosten in abgelegenen Anlagen, die für Techniker nur begrenzt zugänglich sind.

Beim Schalten von Kondensatoren mit bis zu 400 A bei 7,2 kV werden Vakuumschütze für das tägliche Ein- und Ausschalten von Kompensationsanlagen eingesetzt. Die dielektrische Rückstellgeschwindigkeit verhindert ein Wiedereinschalten während der Erregung des Kondensators und schützt sowohl das Schütz als auch die Kondensatorbatterie vor transienten Schäden.

Lichtbogenöfen und Induktionserwärmungsanlagen erfordern Schaltgeräte, die Hochfrequenztransienten standhalten können. Die Arbeitszyklen der Öfen erfordern oft mehr als 500 Schaltungen pro Tag mit Lastströmen von bis zu 630 A. Die versiegelte Vakuumumgebung beseitigt Kontaminationsprobleme, die in der Atmosphäre von Stahlwerken auftreten.

XBRELE's Vakuumschütz-Produktpalette deckt diese industriellen Anwendungen mit Baureihen ab, die für bestimmte Betriebskategorien und Umweltbedingungen optimiert sind.

XBRELE stellt Vakuumschütze in mehreren Baureihen her - JCZ, CKG und spezielle Konfigurationen - die für Motorsteuerungen, Kondensatorschaltungen und Transformatoranwendungen von 3,3 kV bis 12 kV konzipiert sind.

Die technische Unterstützung umfasst die Überprüfung der Anwendung, die Analyse der Sicherungskoordination und die Überprüfung des Arbeitszyklus. Kundenspezifische Konfigurationen berücksichtigen spezifische Steuerspannungen, erweiterte Kriechstromanforderungen und Hilfskontaktanordnungen.

Für eine technische Beratung oder ein Produktangebot wenden Sie sich bitte an unser Vakuumschütz-Fertigungsteam direkt.

F: Wie lange hält ein Vakuumschütz im typischen industriellen Einsatz?

A: Bei AC-3-Motorschaltbetrieb erreichen Vakuumschütze in der Regel 300.000-500.000 elektrische Schaltspiele, bevor ein Kontaktwechsel erforderlich wird. Die mechanische Lebensdauer übersteigt oft 1 Million Schaltspiele. Die tatsächliche Lebensdauer hängt von der Schalthäufigkeit, der Stromstärke und den Umgebungsbedingungen ab.

F: Kann ein Vakuumschütz einen Leistungsschalter für den Motorschutz ersetzen?

A: Nein. Vakuumschütze benötigen koordinierte, vorgeschaltete Sicherungen für den Kurzschlussschutz, da ihr Ausschaltvermögen auf 2-5 kA begrenzt ist. Leistungsschalter bieten eine unabhängige Fehlerunterbrechung bei 25-50 kA ohne Sicherungskoordination.

F: Welche Wartung ist bei einem Vakuumschütz erforderlich?

A: Vakuumschütze sind aufgrund der dichten Unterbrecherkonstruktion weitgehend wartungsfrei. Die regelmäßige Inspektion konzentriert sich auf die Hilfskontakte, die Klemmen der Steuerspule und die mechanischen Gestänge. Die Intervalle für den Austausch der Kontakte hängen von der Anzahl der Schaltvorgänge und der Einschaltdauer ab.

F: Warum sind für Kondensatorbatterieanwendungen spezielle Vakuumschützleistungen erforderlich?

A: Die Erregung eines Kondensators erzeugt Einschaltströme, die 20-mal höher sind als der Nennwert, mit Hochfrequenztransienten, die bis zu 4.000 Hz erreichen. Nur Schütze, die für den AC-6b-Betrieb ausgelegt sind, können diese Belastungen bewältigen, ohne dass es zu Kontaktverschweißungen oder vorzeitigen Unterbrecherausfällen kommt.

F: Worin besteht der Unterschied zwischen den Betriebsklassen AC-3 und AC-4?

A: AC-3-Betrieb bedeutet die Unterbrechung des normalen Betriebsstroms bei etwa dem Nennwert, typisch für Motor-Start-Stopp-Anwendungen. Der AC-4-Betrieb erfordert eine Unterbrechung während des Motorlaufs oder der Umkehrung, wenn der Strom bei 6× des Nennwerts verbleibt - eine wesentlich schwerwiegendere Auswirkung auf die Kontakterosion.

F: Funktionieren Vakuumschütze in großen Höhen?

A: Standard-Vakuumschütze sind für Höhenlagen bis zu 1.000 m ausgelegt. Oberhalb dieser Höhe nimmt die Isolationsfestigkeit der Außenluft ab, so dass entweder ein Derating oder Schütze mit verlängerten Kriechstrecken erforderlich sind. Die Vakuumschaltröhre selbst ist von der Höhe nicht betroffen, da sie in einer geschlossenen Umgebung arbeitet.

F: Wie verhält sich der Kontaktöffnungsabstand zwischen Schützen und Leistungsschaltern?

A: Vakuumschütze verwenden 3-6 mm Kontaktabstand für Spannungen bis zu 12 kV, während Vakuum-Leistungsschalter 8-12 mm Abstand für den Fehlerunterbrechungsbetrieb benötigen. Der kleinere Spalt ermöglicht einen schnelleren Betrieb und eine geringere Betätigungsenergie bei Schützkonstruktionen.