Need Full Specifications?

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

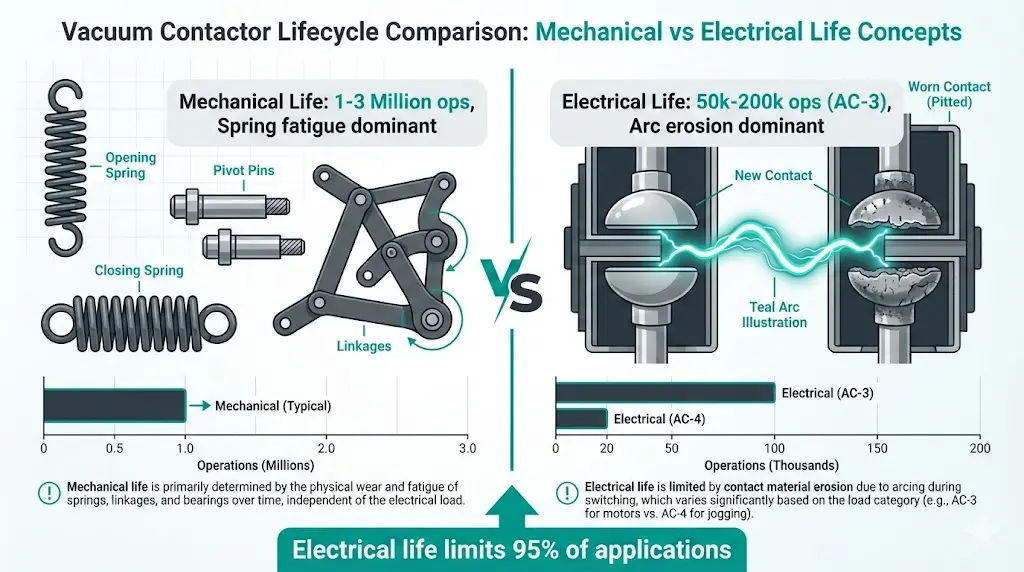

Vacuum contactor datasheets specify two distinct endurance ratings that define replacement timing: mechanical life (number of no-load operations before mechanical wear necessitates overhaul, typically 1-3 million cycles) and electrical life (load-breaking operations before contact erosion exceeds limits, typically 50,000-200,000 cycles depending on utilization category). The critical insight most maintenance planners miss: electrical life determines replacement in 95% of industrial applications because contactors operate under load far more frequently than empty. A 400 A contactor rated for 1 million mechanical operations and 100,000 electrical operations (AC-3, 400 V) reaches electrical end-of-life at 100,000 cycles—leaving 900,000 unused mechanical capacity. Conversely, a contactor controlling a motor that starts/stops 50 times daily reaches 100,000 electrical cycles in 5.5 years while mechanical components remain serviceable.

The confusion compounds when procurement decisions prioritize mechanical life specifications (“this brand offers 2 million vs 1 million cycles—it’s twice as durable”) without considering actual duty cycle. A paper mill operating contactors 8-12 times per day in AC-3 duty (motor starting) exhausts electrical life in 20-30 years but mechanical life in 400-600 years—the mechanical endurance difference is irrelevant. In contrast, a semiconductor fabrication facility cycling wafer-handling equipment 200 times daily in AC-4 duty (plugging/jogging) may exhaust both electrical and mechanical life simultaneously, making total endurance the critical selection criterion.

This guide explains the physics behind mechanical vs electrical wear, how IEC 60947-4-1 utilization categories govern electrical life ratings, field measurement methods to predict remaining life, and maintenance strategies that extend endurance by addressing the limiting factor (contacts vs mechanisms).

Mechanical life measures operations without load current—energizing the closing coil, moving contacts together, then opening via spring force. No arc forms because no current interrupts. Wear accumulates from:

Typical mechanical life ratings (IEC 60947-4-1):

• Industrial contactors (12-630 A): 1-3 million operations

• Mining/heavy-duty contactors: 500,000-1 million (rugged design, higher contact force → more spring stress)

• Miniature contactors (9-40 A): 10 million (lighter springs, less wear per cycle)

Mechanical life assumes: No-load switching at rated voltage, 20°C ambient, 300-600 ops/hour maximum cycling rate (thermal equilibrium maintained).

What limits mechanical life: Spring tension degradation is the dominant failure mode. Opening spring force must overcome magnetic holding force plus contact welding (if any arcing occurred). When spring weakens to <80% initial force, contactor either fails to open reliably or requires extended opening time (dangerous if interrupting fault current). Measuring spring force requires disassembly + force gauge; simpler field indicator is increasing opening time via timing tests (see below).

Mechanical life vs operating frequency: Cycling rate affects lubrication temperature. At 600 ops/hour, friction heating raises lubricant temperature 20-40°C above ambient → accelerated oxidation → viscosity loss → higher wear rates. Manufacturers specify maximum continuous cycling rates (e.g., “600 ops/hr for 1 hour maximum, then 2 hour rest”) to prevent thermal damage.

Understanding vacuum contactor advantages helps contextualize why mechanical simplicity (no arc chutes, fewer moving parts than air contactors) extends mechanical life.

Electrical life measures load-breaking operations where contact separation under current creates an arc. Arc energy vaporizes contact material (copper-chromium alloy in vacuum interrupters), eroding surface geometry and increasing contact resistance. IEC 60947-4-1 defines utilization categories (AC-1 through AC-4) that govern electrical life ratings based on inrush current, power factor, and switching frequency.

AC-1: Resistive loads (heaters, lighting)

AC-3: Normal motor starting (squirrel-cage induction motors)

AC-4: Plugging, inching, jogging (repeated starts under load)

Electrical life comparison: 400 A contactor, 400 V (typical manufacturer ratings):

• AC-1 (resistive): 600,000 ops at 400 A

• AC-3 (motor starting, open at 1× I_rated): 150,000 ops at 400 A

• AC-4 (jogging, open at 6× I_rated): 20,000 ops at 400 A

Note: AC-4 electrical life is 7.5× shorter than AC-3 despite identical mechanical operations—arc energy is the differentiator.

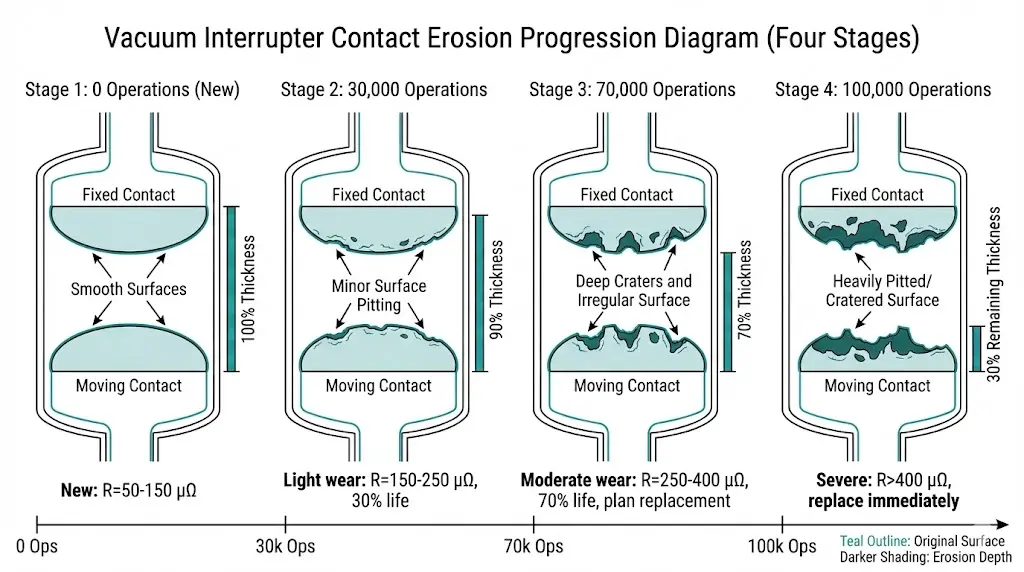

Arc erosion mechanism: When contacts separate under load, metal vapor ionizes in the vacuum gap → arc forms → current continues flowing through plasma → at AC current zero-crossing, arc extinguishes. During arcing (0.5-2 ms per half-cycle), contact temperature reaches 3,000-5,000°C → copper-chromium alloy vaporizes → material transfers from cathode (negative contact) to anode → non-uniform erosion creates pitting and crater formation.

Critical threshold: When contact erosion exceeds 30% of original thickness or contact resistance >500 µΩ (measured via micro-ohmmeter), interruption capability degrades—arc energy increases, welding risk rises, and voltage withstand margin shrinks.

For field measurement of contact condition, see vacuum contactor contact wear measurement.

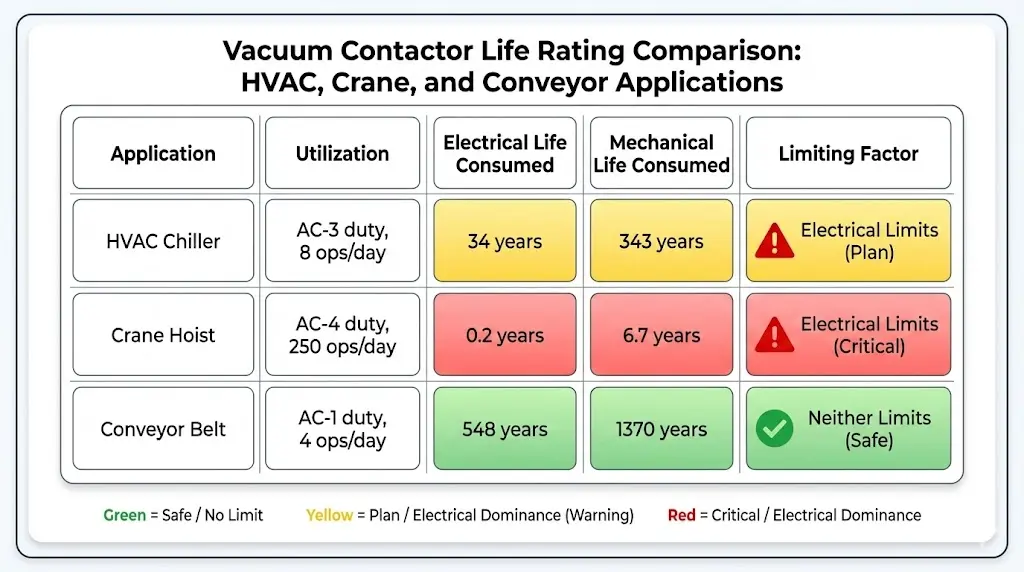

The limiting factor—mechanical or electrical life—depends on duty cycle and utilization category:

Contactor: 300 A, 1 million mechanical / 100,000 electrical (AC-3) operations

Annual cycles: 8 starts/day × 365 days = 2,920 operations/year

Time to electrical end-of-life: 100,000 / 2,920 = 34 years

Time to mechanical end-of-life: 1,000,000 / 2,920 = 343 years

Result: Electrical life determines replacement. Mechanical components remain serviceable. Focus maintenance on contact resistance monitoring, not spring replacement.

Contactor: 400 A, 500,000 mechanical / 15,000 electrical (AC-4) operations

Annual cycles: 250 starts/day × 300 working days = 75,000 operations/year

Time to electrical end-of-life: 15,000 / 75,000 = 0.2 years (2.4 months)

Time to mechanical end-of-life: 500,000 / 75,000 = 6.7 years

Result: Electrical life exhausted in months. This application requires either: (1) Oversized contactor rated for AC-4 duty with 50,000+ electrical operations, or (2) Frequent contact replacement every 3-6 months.

Contactor: 200 A resistive load, 2 million mechanical / 800,000 electrical (AC-1) operations

Annual cycles: 4 starts/day × 365 days = 1,460 operations/year

Time to electrical end-of-life: 800,000 / 1,460 = 548 years

Time to mechanical end-of-life: 2,000,000 / 1,460 = 1,370 years

Result: Neither limit reached in practical service life (25-30 years). Contactor replacement driven by other factors (coil insulation failure, external damage, facility upgrade).

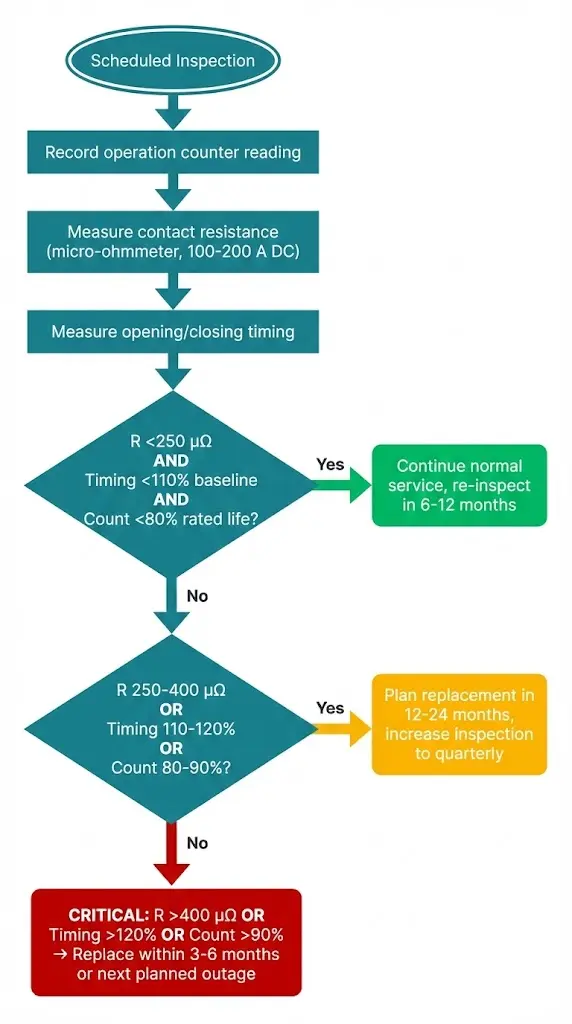

Rather than waiting for failure, predictive maintenance measures degradation to schedule replacement during planned outages.

Equipment: Micro-ohmmeter (100-200 A DC, ±1 µΩ resolution)

Procedure:

Contact resistance interpretation (400 A contactor, 12 kV class):

• New contacts: 50-150 µΩ (smooth surfaces, full contact area)

• Light wear (0-30% electrical life): 150-250 µΩ (minor pitting, still acceptable)

• Moderate wear (30-70% life): 250-400 µΩ (plan replacement within 12-24 months)

• Heavy wear (>70% life): 400-500 µΩ (replace within 3-6 months)

• Critical (>80% life): >500 µΩ (replace immediately, risk of welding or failure to interrupt)

Trending analysis: Measure contact resistance quarterly. If resistance increases >50 µΩ/year, contacts approaching end-of-life. Accelerating degradation (e.g., 20 µΩ increase in 6 months after 3 years of stable operation) indicates worsening arc erosion—possibly from overload conditions or voltage transients.

Equipment: VCB timing analyzer (measures opening/closing times)

Procedure:

Spring degradation indicators:

Example: Contactor baseline opening time 35 ms (new). After 500,000 mechanical operations, opening time 42 ms (+20%). Spring force weakened—risk of failure to interrupt under fault current. Replace opening spring or entire mechanism.

Modern contactors include built-in operation counters (mechanical or electronic) that track total cycles. Compare counter reading to rated life:

Electrical life utilization = (Counter reading) / (Rated electrical life for actual utilization category)

Mechanical life utilization = (Counter reading) / (Rated mechanical life)

Replace when either exceeds 80-90% (conservative) or 100% (aggressive, but risks unexpected failures).

Three approaches maximize contactor endurance—two address electrical degradation, one addresses mechanical wear.

For contactors with replaceable vacuum interrupters, renew electrical life by swapping worn contacts while retaining serviceable mechanism.

Procedure:

Economics: Contact replacement costs 30-50% of new contactor price. Justifiable when mechanism shows <50% mechanical life utilization and contactor is <15 years old (coil insulation still healthy).

Limitations: Not all contactors have field-replaceable contacts (integrated designs require complete unit replacement).

If actual duty is less severe than design assumptions, extend electrical life by recalculating based on true conditions.

Example: Contactor rated for AC-4 (plugging duty) but actually operates AC-3 (normal starting) because application changed. AC-3 electrical life is 5-8× longer than AC-4 for same contactor → adjust replacement schedule accordingly.

Verification: Analyze one month of operation logs:

For high-cycle AC-1/AC-3 applications where mechanical wear dominates (rare, but occurs in conveyor systems with hundreds of daily cycles):

Procedure:

Cost: $1,000-$3,000 labor + parts (20-30% of new contactor). Restores mechanical life to 80-90% of new condition.

Vacuum contactor endurance ratings divide into mechanical life (1-3 million operations, limited by spring fatigue and pivot wear) and electrical life (50,000-200,000 operations for AC-3 motor starting, 10,000-50,000 for AC-4 plugging, limited by contact erosion from arc energy). In 95% of industrial applications, electrical life determines replacement timing—a 400 A contactor cycling 10 times daily in AC-3 duty reaches 100,000 electrical cycles in 27 years while mechanical components remain serviceable. Exceptions occur in AC-1 resistive loads or ultra-low-frequency applications (<5 ops/day) where both ratings far exceed practical service life.

Field prediction of remaining life uses three measurements: contact resistance (micro-ohmmeter, <250 µΩ acceptable, >400 µΩ replace soon, >500 µΩ critical), mechanical timing (opening time increase >10% indicates spring degradation), and operation counter trending (replace at 80-90% rated life). Maintenance strategies extend endurance by addressing the limiting factor—contact replacement renews electrical life (30-50% cost of new contactor), utilization category recalculation adjusts life ratings if duty less severe than designed, and mechanism overhaul restores mechanical performance (rare, only for high-frequency AC-1 applications).

The key insight: procurement decisions that prioritize mechanical life specifications (“2 million vs 1 million cycles”) ignore the actual limiting factor. A paper mill contactor operating 8 times daily exhausts electrical life in 30 years but mechanical life in 600 years—the extra mechanical endurance provides zero value. Instead, optimize electrical life rating for actual utilization category (AC-3 vs AC-4) and implement contact resistance trending to predict replacement timing 6-12 months in advance—enabling scheduled maintenance during planned outages instead of reactive failures during production runs.

Q1: Why is electrical life 5-50× shorter than mechanical life for the same contactor?

Arc erosion during load breaking vaporizes contact material at rates 1,000-10,000× faster than mechanical friction wear. Each AC-3 operation (motor starting) creates 0.5-2 ms arcing at 3,000-5,000°C, removing ~0.1-1.0 µm of copper-chromium alloy per cycle via vaporization. After 100,000 operations, cumulative erosion reaches 10-100 mm³ (30% of contact thickness for 400 A contactor). In contrast, mechanical wear from springs/pivots removes <0.01 µm/cycle at 20-50°C via abrasion—requiring 1-3 million operations to produce equivalent damage. AC-4 duty (plugging/jogging) interrupts 5-7× rated current, increasing arc energy 25-50× vs AC-3 → electrical life drops to 10,000-50,000 operations while mechanical components unchanged. Result: 400 A contactor rated 1 million mechanical / 100,000 electrical (AC-3) / 20,000 electrical (AC-4)—electrical life is the limiting factor unless application is pure AC-1 resistive switching.

Q2: How do I know if my application is AC-3 or AC-4 utilization category?

Utilization category depends on when contacts open relative to motor current: AC-3 (normal starting): Contacts close to start motor → motor accelerates to full speed (current drops to 1× rated) → contacts open under steady-state current. AC-4 (plugging/jogging): Contacts close → motor begins accelerating → contacts open before motor reaches full speed → interrupt 3-7× rated current. Diagnostic: Record contactor closing duration using operation counter or PLC timer. If contacts remain closed >2-5 seconds (motor acceleration time), likely AC-3. If contacts open within 0.5-2 seconds (motor still accelerating), it’s AC-4. Alternative: Measure current at instant of contact opening using clamp meter with peak-hold—if >2× rated, AC-4 duty. AC-4 applications: cranes (inching), machine tools (jogging for alignment), elevators (floor leveling), conveyors (precise positioning). AC-3 applications: pumps, fans, compressors (run until process complete, then stop).

Q3: Can I replace just the vacuum interrupter contacts without replacing the entire contactor?

Yes, if manufacturer designed field-replaceable contacts. Typical procedure: (1) De-energize and discharge contactor; (2) Remove pole assembly covers; (3) Disconnect vacuum bottle from linkage (snap rings or bolts); (4) Install new factory-sealed interrupter; (5) Reassemble and test (contact resistance, timing, high-voltage withstand). Cost: $500-$2,000 per pole for 12 kV class interrupters (30-50% of new contactor). Justifiable when: Mechanism shows <50% mechanical life utilization (timing tests normal, no spring degradation), contactor <15 years old (coil insulation healthy), and contact resistance >400 µΩ or >80,000 electrical operations consumed. Not all contactors allow replacement—integrated designs bond interrupter to mechanism (ABB VM1, some XBRELE models). Check manufacturer documentation or consult service manual before assuming replaceability.

Q4: What contact resistance reading indicates I should replace the contactor?

Use trending analysis combined with absolute thresholds: Immediate replacement (critical): R >500 µΩ—risk of welding, failure to interrupt, or voltage flashover. Replace within 3-6 months: R 400-500 µΩ or >50% increase over 12 months—accelerating degradation indicates approaching failure. Plan replacement 12-24 months: R 250-400 µΩ and stable trending. Continue service: R <250 µΩ. New baseline: 50-150 µΩ for 12-40.5 kV contactors (varies by manufacturer, pole size). More critical than absolute value: Growth rate. A contactor at 300 µΩ stable for 3 years is safer than 250 µΩ that increased from 180 µΩ in 6 months. Measure quarterly using micro-ohmmeter (100-200 A DC, ±1 µΩ resolution). Plot R vs operation count—linear increase is normal aging, exponential increase signals failure mode (severe pitting, misalignment, contamination).

Q5: Does frequent starting reduce mechanical life even if electrical life is not exceeded?

Yes—cycling rate affects mechanical wear through thermal degradation of lubrication and spring fatigue acceleration. At low frequency (<10 ops/hour), mechanical components remain cool (~ambient +10-20°C), lubrication viscosity stable, springs cycle within design stress. At high frequency (>300 ops/hour), friction heating raises lubricant temperature 30-50°C above ambient → oxidation accelerates → viscosity drops → metal-on-metal contact increases → wear rate rises 3-5×. Additionally, rapid spring cycling reduces fatigue life via thermal stress (springs heat during compression, cool during extension → thermal cycling compounds mechanical fatigue). IEC 60947-4-1 limits: Maximum 300-600 ops/hour continuous (manufacturer-specific). Exceeding this derates mechanical life 30-50%. Solution for high-frequency: (1) Select contactor rated for continuous high cycling (mining-duty versions with enhanced lubrication/spring materials); (2) Implement forced cooling (panel fans maintaining <40°C ambient); (3) Use soft-start to reduce operations (VFD ramps vs hard starts).

Q6: How does ambient temperature affect mechanical vs electrical life?

Mechanical life: High ambient (>40°C) accelerates lubrication oxidation (viscosity loss → friction increase → wear rate ×2-3 at 60°C vs 20°C) and weakens spring materials (creep increases, tension loss accelerates 20-30% at 50°C). Low ambient (<0°C) stiffens lubricants (viscosity increases → higher friction on first operations → cold-start wear spikes). Electrical life: Temperature affects contact material properties minimally—arc erosion rate changes <10% across -20°C to +60°C because arcing occurs at 3,000-5,000°C (ambient irrelevant). However, high ambient reduces current rating (derating required to prevent overheating) → if contactor operates near derated limit, arc energy per operation increases → electrical life shortens 10-20%. Combined effect: At 60°C ambient, mechanical life reduced 30-40%, electrical life reduced 10-15% (if load derated properly). For extreme temperatures, specify extended-range contactor (Class H insulation, synthetic lubricants rated -40°C to +85°C, enhanced spring materials).

Q7: What is the most cost-effective way to extend contactor life in AC-4 (plugging) applications?

Three strategies in order of cost-effectiveness: (1) Oversize contactor for AC-4 duty: Select unit with 3-5× higher AC-4 electrical life rating than calculated needs. Example: Application requires 15,000 AC-4 operations—specify contactor rated 50,000-75,000 AC-4 ops. Cost premium 30-50% vs standard AC-3 rated contactor, but extends replacement interval from 2 years to 6-8 years → lifecycle cost savings via fewer replacements. (2) Soft-start to reduce inrush: Use solid-state soft-start or VFD to limit inrush to 2-3× rated (vs 6-7× for hard start) → arc energy drops 70-80% → electrical life extends 3-5×. Cost: $500-$2,000 for soft-start module. (3) Change application to AC-3: Redesign process to allow motor full acceleration before opening contacts—replaces plugging with coasting stop or VFD ramp-down. Converts AC-4 to AC-3 duty → electrical life increases 5-10×. Example: Crane hoist—instead of instant reverse (plugging), use VFD controlled deceleration. Most cost-effective long-term but requires control system modification.