Need Full Specifications?

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

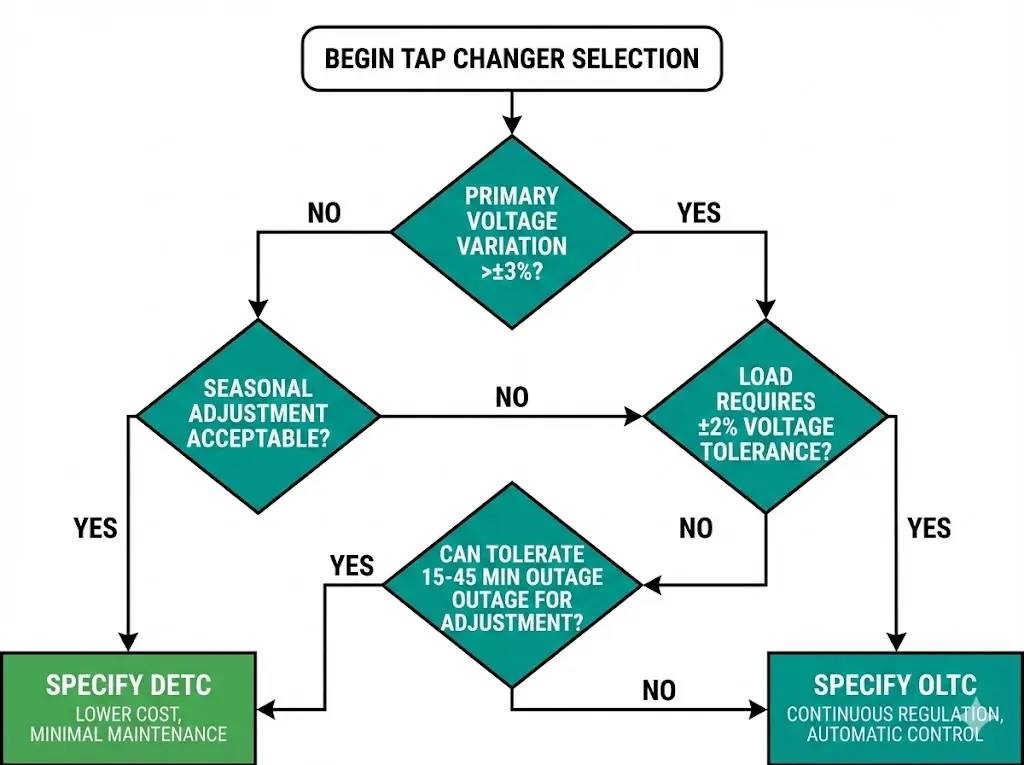

Transformer voltage regulation capability ranks among the most consequential decisions in procurement. The choice between an on-load tap changer (OLTC) and an off-circuit tap changer (DETC) determines whether voltage adjustment requires a service outage—or happens seamlessly while load current flows.

Get this specification wrong, and you face either unnecessary capital and maintenance costs or operational limitations that constrain system performance for decades. This guide provides the engineering rationale and specification language that separates informed purchasing from costly mismatches.

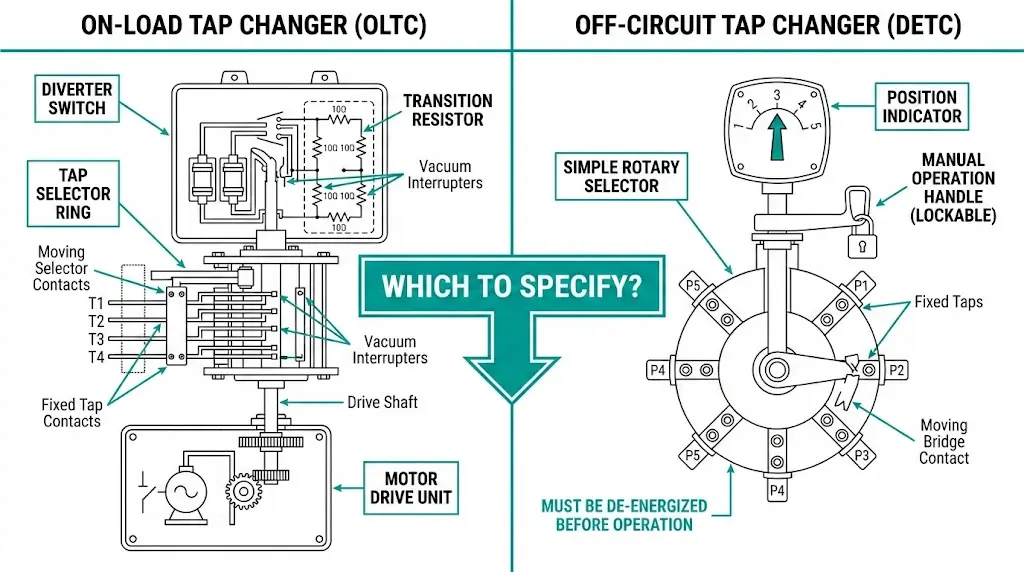

Both technologies adjust transformer turns ratio by connecting different portions of a tapped winding. The critical difference lies in when adjustment occurs.

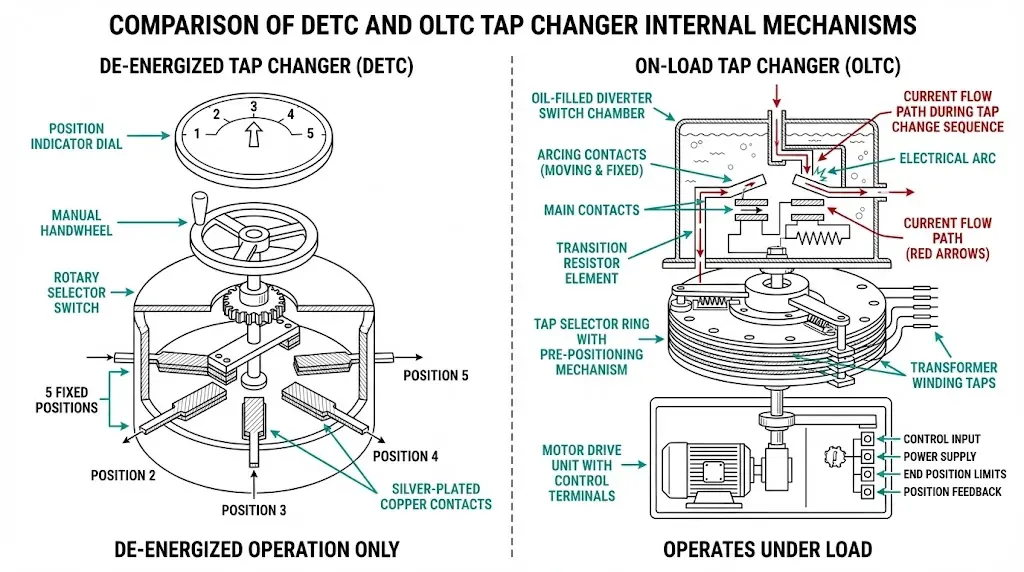

An off-circuit tap changer (DETC) operates only when the transformer is de-energized and isolated. The construction is mechanically straightforward: a rotary selector with silver-plated copper contacts, manual or motor-driven positioning, and mechanical locking. No arc-interrupting capability exists because no current flows during switching. Standard designs offer ±2 × 2.5% regulation (five positions). Changing taps requires isolation, switching, and re-energization—typically 15–45 minutes.

An on-load tap changer (OLTC) performs adjustment while the transformer remains energized and loaded. This demands sophisticated mechanisms: a diverter switch for current interruption, a tap selector for pre-positioning, transition resistors or reactors to limit circulating current during bridging, and motor drives with control logic. The switching sequence completes in 40–80 milliseconds.

Resistor-type OLTCs dominate European and international practice. Reactor-type designs remain common in North American distribution applications. Both achieve regulation ranges of ±10% to ±15% with 17–33 tap positions, providing voltage steps of 0.625% to 1.25%.

The voltage adjustment per tap step follows Faraday’s law directly—changing effective turns modifies the voltage ratio proportionally. IEC 60076-1 requires tapping windings to handle full rated current while maintaining insulation integrity at each position.

[Expert Insight: Field Deployment Observations]

- In 50+ industrial substation deployments, resistor-type OLTCs with 0.5–2.0 Ω transition resistors consistently limit circulating current within design bounds during the switching interval

- Vacuum-type OLTC diverter switches operating below 10⁻³ Pa achieve arc extinction without oil degradation—increasingly specified for 35 kV class transformers

- Off-circuit tap changer contact resistance below 50 μΩ correlates with trouble-free operation over 30+ year service life

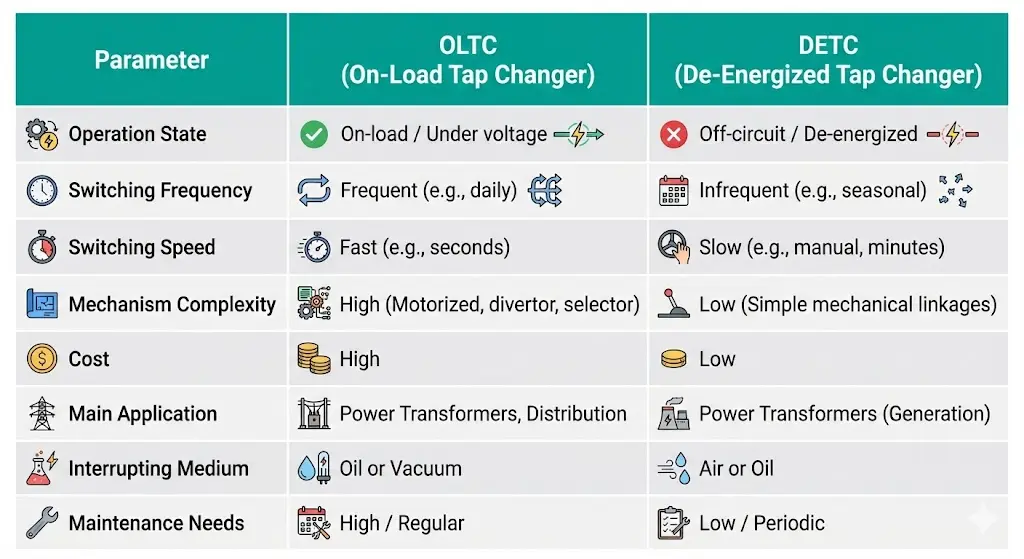

The specification differences between these technologies affect every aspect of transformer operation and ownership cost.

Here is the comparison table for quick review :

| Parameter | Off-Circuit (DETC) | On-Load (OLTC) |

|---|---|---|

| Adjust while energized | No | Yes |

| Typical regulation range | ±5% | ±10% to ±15% |

| Tap positions | 3–5 | 9–33 |

| Voltage step per tap | 2.5% typical | 0.625%–1.25% |

| Annual switching operations | 2–12 | 5,000–100,000+ |

| Contact wear mechanism | Minimal (no arcing) | Arc erosion, contact coking |

| Maintenance interval | 10+ years | 3–7 years |

| Cost impact on transformer | Baseline | +15%–40% |

IEC 60214-1 governs OLTC performance requirements, specifying minimum 500,000 mechanical operations and 50,000 operations at rated through-current. Off-circuit tap changers require far fewer validated operations—typically 50–100 cycles over service life.

The cost premium for OLTC varies significantly with transformer MVA rating. On smaller units under 2.5 MVA, the tap changer may represent 30–40% of total cost. On larger power transformers, the percentage drops but absolute cost increases.

DETC technology suits applications where voltage stability and outage tolerance align:

A manufacturing facility with known seasonal loading can adjust taps during spring and fall maintenance. The simpler DETC mechanism introduces fewer failure modes and near-zero maintenance burden.

OLTC becomes necessary when operational requirements preclude de-energization:

The renewable integration case deserves emphasis. Solar and wind generation creates voltage profiles that change faster than any manual adjustment process can track. Fixed taps cannot compensate—OLTC with automatic voltage regulation becomes essential.

Vague specifications invite substitution and mismatch. Detailed requirements ensure the delivered equipment matches application needs.

DETC Specification Template:

TAP CHANGER REQUIREMENTS — OFF-CIRCUIT TYPE

1. Type: De-energized tap changer (DETC), externally operable

2. Tapping range: ±2 × 2.5% (5 positions)

3. Tapped winding: [HV/LV] — state with engineering justification

4. Operating mechanism: Manual handwheel with position locking

5. Position indicator: Mechanical dial, ground-level visibility

6. Interlock: Electrical interlock preventing energized operation

7. Contact material: Silver-plated copper minimum

OLTC Specification Template:

TAP CHANGER REQUIREMENTS — ON-LOAD TYPE

1. Type: On-load tap changer, [reactor/resistor] type

2. Tapping range: ±10% in 17 steps (1.25% per step)

3. Tapped winding: HV neutral end

4. Diverter switch: [Oil-immersed/Vacuum] type

5. Motor drive: 3-phase, [voltage], local/remote capability

6. Control interface: AVR relay compatible, tap position transmitter (4-20mA)

7. Operation counter: Mechanical + electronic with alarm setpoint

8. Service life: Minimum 100,000 operations before major overhaul

9. Approved manufacturers: [List if required]

Generic “OLTC included” language without parameters invites the lowest-cost substitution. Specify diverter switch technology explicitly. Define automatic voltage regulator interface requirements—an OLTC without proper control integration delivers limited value.

HV versus LV tapping affects impedance variation and fault current levels. The specification should state the tapped winding with clear justification. For comprehensive transformer specification support, XBRELE’s engineering team provides distribution transformer technical guidance covering all major parameters.

Initial purchase price represents only part of total ownership cost. The maintenance profiles differ dramatically.

DETC maintenance is minimal: visual inspection during routine transformer service, contact resistance measurement every 5–10 years, occasional mechanism lubrication. No oil processing requirements. Many units operate 30+ years without significant intervention.

OLTC maintenance demands systematic programs:

Vacuum diverter switches change this equation. Operating in high vacuum, they eliminate oil degradation from arcing and extend contact life to 300,000–500,000 operations. The technology parallels vacuum interrupter principles used in medium-voltage switchgear. Higher initial cost may prove economical when lifecycle maintenance is factored.

[Expert Insight: Lifecycle Cost Factors]

- Oil-immersed OLTC diverter oil costs $800–2,000 per change; vacuum types eliminate this recurring expense

- High-cycling applications (>20,000 operations/year) reach maintenance thresholds 3–5× faster than typical utility substation duty

- Contact erosion rates of 0.02–0.05 mm per 1,000 operations determine inspection scheduling; vacuum contacts erode slower

- Total 20-year maintenance cost for oil-type OLTC may exceed 50% of initial tap changer cost

Five errors appear repeatedly in procurement documents:

Reference IEC 60214-1 for tap changer performance requirements and test methods when developing specifications. For system-level coordination between transformers and protection equipment, see XBRELE’s switchgear component integration guidance.

Tap changer selection cannot occur in isolation from overall transformer specification. The tap changer rating must align with MVA capacity, short-circuit withstand, insulation coordination, control architecture, and site environmental conditions.

XBRELE’s engineering team supports buyers through complete specification development:

For distribution transformer inquiries including tap changer requirements, contact our transformer engineering group. The transformer will operate for 30–40 years on decisions made during procurement. Precision now prevents problems later.

Q: Can I upgrade from DETC to OLTC after transformer installation?

A: Retrofitting is not practical—winding tap arrangements and tank geometry differ fundamentally between designs. The tap changer type must be specified correctly during initial procurement.

Q: How many tap changes can an OLTC perform before requiring major overhaul?

A: Oil-immersed OLTCs typically require overhaul at 100,000–150,000 operations, while vacuum diverter designs extend to 300,000–500,000 operations depending on manufacturer and switching duty severity.

Q: Does OLTC diverter oil require separate testing from main tank oil?

A: Yes. Diverter switch oil accumulates arcing byproducts (acetylene, hydrogen) at concentrations that would indicate fault conditions in main tank oil. Separate sampling and analysis is mandatory for accurate condition assessment.

Q: What regulation range should I specify if voltage variation data is incomplete?

A: Specify ±10% minimum for OLTC applications as a conservative baseline. Conduct system voltage studies before finalizing if cost optimization or tighter regulation bandwidth is required.

Q: Is reactor-type or resistor-type OLTC preferred?

A: Resistor-type designs dominate international practice due to faster switching (40–60 ms) and more compact construction. Reactor-type remains established in North American distribution. Both technologies perform reliably when properly specified and maintained.

Q: When does vacuum diverter switch technology justify its cost premium?

A: Specify vacuum diverters for high-cycling applications exceeding 20,000 operations annually, installations where oil handling is restricted, or projects where reduced lifecycle maintenance cost outweighs initial premium.