Need Full Specifications?

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

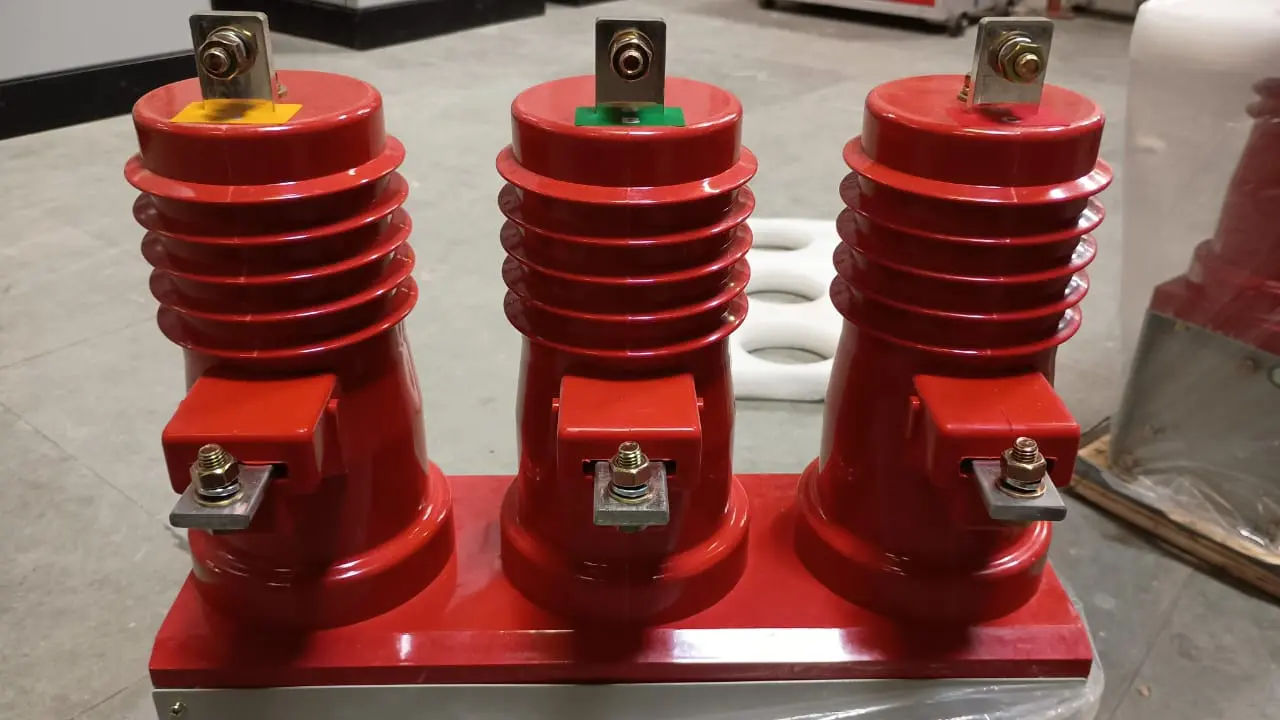

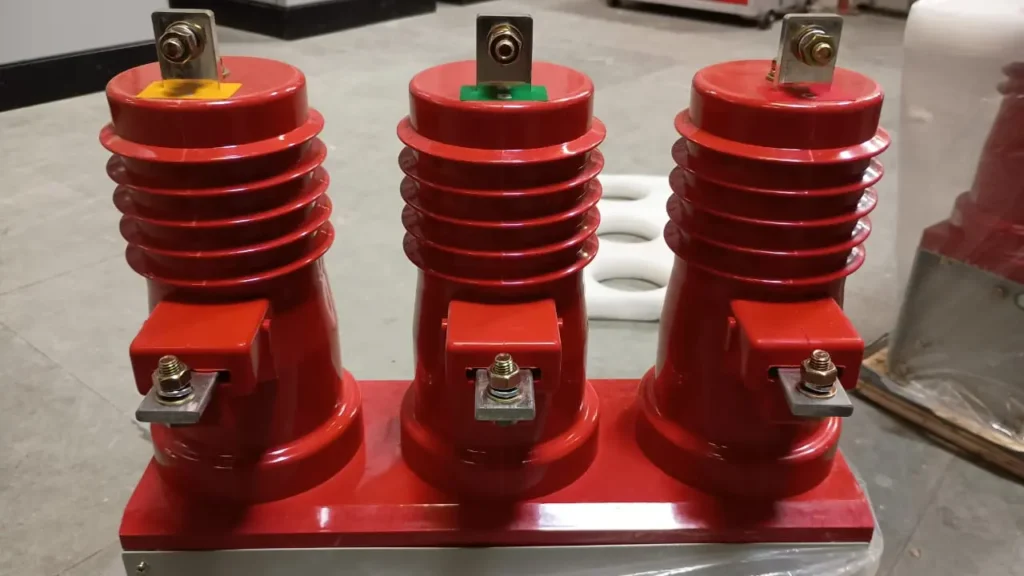

In the high-stakes landscape of industrial power distribution, the vacuum contactor is the silent workhorse. Unlike circuit breakers, which stand guard against catastrophic faults, contactors are the marathon runners, designed to switch motors, transformers, and capacitor banks hundreds of thousands of times. However, the reliability of a vacuum contactor is only as good as its maintenance and application.

At XBRELE, we have analyzed decades of field data. We found that 80% of failures—from welded contacts to coil burnouts—are preventable. As a specialized Vacuum Contactor Manufacturer, we know that facility managers can no longer afford a “run-to-failure” strategy. Unplanned downtime can cost industrial facilities thousands of dollars per hour, making proactive maintenance not just an operational task, but a financial necessity.

This guide moves beyond surface-level observations to provide technical insights into the Top 10 Vacuum Contactor Failure Causes, actionable troubleshooting tables, and real-world case studies to help you build a resilient infrastructure for 2025.

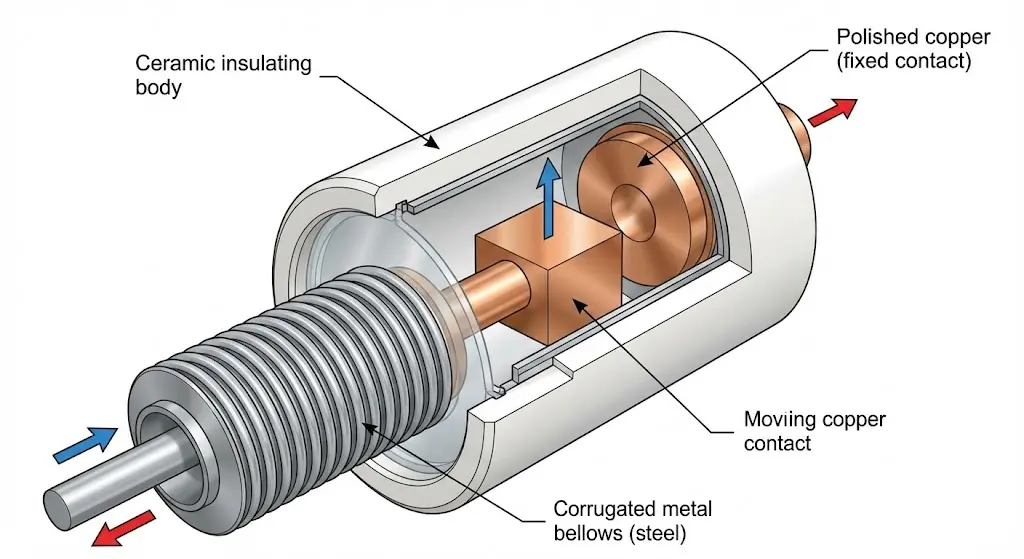

To prevent failure, one must understand the physics inside the device. A vacuum contactor switches high-current loads within a hermetically sealed vacuum bottle (interrupter).

Why the Vacuum? The vacuum environment offers superior dielectric strength. When the contacts open, the metal vapor arc is extinguished rapidly—often at the first current zero-crossing. For a deeper dive into this physics, read our technical breakdown: How Does a Vacuum Contactor Extinguish Arc?

This mechanism results in:

Note for Engineers: Vacuum contactors are typically designed in accordance with IEC 60470 standard regarding High-voltage alternating current contactors. Compliance with this standard is a baseline for reliability.

A common engineering mistake is treating a contactor like a breaker. While they look similar, their functions differ fundamentally. A Vacuum Circuit Breaker (VCB) is designed to interrupt massive fault currents (short circuits), while a contactor is optimized for frequent load switching (up to 1,200 operations per hour). Confusing these roles is a recipe for disaster.

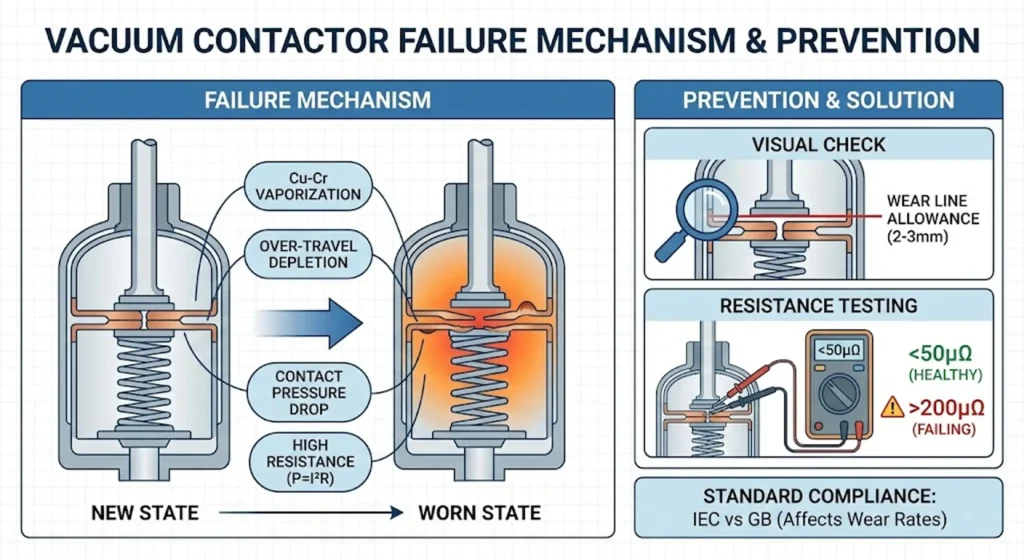

The Mechanism: Every switching operation vaporizes a microscopic amount of the copper-chromium contact material. Over time, the “over-travel” (the compression distance of the contact spring) diminishes. If this is depleted, contact pressure drops, leading to high resistance. As resistance rises (P=I²R), heat generation increases exponentially, potentially causing the contacts to weld shut.

Prevention & Solution:

The Mechanism: The coil is the heart of the magnetic actuator. Failures here are often due to inter-turn short circuits caused by insulation breakdown from heat, aging, or voltage spikes. In DC-operated coils, failure of the “economizer” circuit (which reduces current after closing) is a primary cause of burnout.

Prevention & Solution:

The Mechanism:

Prevention & Solution:

The Mechanism: “Jogging” a motor (rapid start/stop for positioning) generates massive arc energy and heat. Standard AC-3 rated contactors are designed for normal starting and stopping, not the extreme stress of AC-4 duty cycles. This is particularly common in mining hoists, cranes, and conveyors.

Prevention & Solution:

The Mechanism: Vacuum contactors rely on precise mechanical linkages. Vibration from nearby heavy machinery (crushers, ball mills) can loosen mounting bolts. This leads to misalignment, causing uneven contact pressure or “single-phasing,” where only two of the three phases close properly.

Prevention & Solution:

The Mechanism: In high-altitude or dusty environments, conductive dust (like coal dust or metallic shavings) accumulates on the insulating housing of the vacuum bottle. In humid conditions, this creates a conductive path, leading to tracking and eventual flashover to ground.

Prevention & Solution:

The Mechanism: A vacuum contactor is not a safety breaking device for short circuits. If a fault occurs and the upstream fuse is too slow, the fault current may exceed the contactor’s short-time withstand current (Icw), causing the contacts to weld together permanently due to the intense electromagnetic forces.

Prevention & Solution:

The Mechanism: Installation errors are leading causes of “infant mortality” in equipment. Common issues include stressing the busbars (forcing them to align with terminals) or incorrect grounding. Physical stress on the terminals can crack the ceramic seal of the vacuum bottle, causing an immediate loss of vacuum.

Prevention & Solution:

The Mechanism: “Set it and forget it” is a dangerous philosophy. Neglect allows minor issues—like loosening return springs, slight rust on linkages, or dried lubrication—to compound into catastrophic mechanical jams or electrical failures.

Prevention & Solution:

The Mechanism: Even the best hermetic seals are not perfect forever. Over a lifespan of 15-20 years, micro-leaks can occur. As the internal pressure rises towards atmospheric levels, the dielectric strength fails, leading to an inability to extinguish the arc.

Prevention & Solution:

The Scenario: An open-pit mine operating at 2,500m altitude in Western China experienced frequent contactor failures on their main hoist motor (6kV, 800kW). The contactors were failing every 6 months, causing costly production halts.

The Diagnosis: Upon inspection by XBRELE engineers, two root causes were identified:

The Solution: We replaced the units with XBRELE JCZ Series High-Altitude Vacuum Contactors, which feature enhanced insulation distances and larger cooling fins. We also advised the client to install a “Soft Start” bypass system to reduce arc energy during jogging.

The Result: Since the upgrade 3 years ago, the mine has experienced zero unplanned downtime related to contactor failure. This highlights why selecting the right specialized equipment—such as Mining Vacuum Contactors—is crucial.

If your vacuum contactor is acting up, use this quick reference table to identify the likely culprit.

| Symptom | Possible Cause | Recommended Action |

|---|---|---|

| Loud Buzzing / Humming | Dirty magnet faces; Broken shading coil; Low voltage. | Clean magnet surfaces; Check control voltage; Replace shading coil. |

| Fails to Close | Blown fuse; Coil burnout; Mechanical jam; Wire break. | Check control circuit fuses; Measure coil resistance; Check mechanism manually. |

| Closes then Opens Immediately | “Economizer” switch failure; Voltage dip under load. | Check economizer wiring; Check CPT capacity for voltage drop. |

| Overheating Terminals | Loose connection; Oxidized busbar; Internal contact wear. | Torque bolts to spec; Clean contact surfaces; Perform micro-ohm test. |

| Welded Contacts | Short circuit downstream; Excessive jogging; Low contact pressure. | Check for motor faults; Verify fuse coordination; Check spring pressure. |

For facility managers and technicians, consistency is key. Use this checklist annually to ensure your XBRELE vacuum contactors remain in peak condition.

| Inspection Category | Task Description | Passing Criteria |

|---|---|---|

| 1. Visual Inspection | Check vacuum bottle for cracks or damage. | No visible cracks on ceramic/glass. |

| Inspect contact wear indicator line. | Wear is within manufacturer limits (<3mm). | |

| Check for dust, soot, or foreign objects. | Surfaces are clean and dry. | |

| 2. Mechanical Check | Manually operate the contactor (Power OFF). | Moves freely without binding or grinding. |

| Check tightness of all bolts and terminals. | Torqued to spec (typically marked with paint). | |

| Inspect return springs and latches. | Springs are intact; no corrosion. | |

| 3. Electrical Testing | Control Voltage Test: Measure coil voltage. | Within 85% – 110% of rated voltage. |

| Contact Resistance: Measure pole resistance. | Resistance < 50-100 µΩ (depends on rating). | |

| Insulation Resistance (Megger): Phase-to-Ground. | > 100 MΩ @ 1000V DC. | |

| Vacuum Integrity (Hi-Pot): AC Withstand Test. | Withstands rated voltage across open contacts (e.g., 20kV for 1 min). | |

| 4. Cleaning | Clean insulating parts with dry, lint-free cloth. | No conductive residue remaining. |

Warning: Always ensure the system is de-energized and grounded before performing maintenance.

Q1: How do I know if a vacuum bottle has lost its vacuum? A: You cannot see a loss of vacuum. The only reliable method is a High-Potential (Hi-Pot) test. If voltage arcs across the open contacts at a level below its rating, the vacuum is compromised.

Q2: Why is my vacuum contactor making a loud buzzing noise? A: A loud hum or buzz usually indicates a problem with the magnetic core. The faces of the magnet may be dirty, misaligned, or the “shading coil” (a small copper ring on the magnet) may be broken. This requires immediate attention to prevent coil burnout.

Q3: Can I repair a vacuum contactor myself? A: Minor maintenance like cleaning, tightening bolts, and replacing auxiliary contacts can be done on-site. However, replacing the vacuum interrupters requires precise calibration of the contact gap and over-travel. We recommend contacting the manufacturer or a certified service partner for internal repairs.

Q4: Is it safe to use a vacuum contactor for a soft starter bypass? A: Yes, this is an excellent application. Since the contactor closes after the motor is up to speed (no inrush current) and opens while the soft starter takes the load, the contactor experiences very little electrical wear, significantly extending its life.

Q5: How often should I grease the mechanical parts? A: Generally, every 3-5 years or every 250,000 operations, depending on the environment. Use only the manufacturer-recommended low-temperature grease (often lithium-based) to avoid hardening in cold weather.

The reliability of your electrical system is a result of the choices you make in equipment selection, installation, and maintenance. By understanding these 10 failure modes, you can transition from reactive repairs to proactive asset management.

From ensuring proper IEC Standards compliance to performing annual Hi-Pot tests, these steps protect your investment.

Looking for high-reliability switching solutions? At XBRELE, we engineer vacuum contactors designed to withstand the toughest industrial environments, from the mines of Asia to the factories of Europe. Whether you need a robust LCZ Series High Voltage Contactor or expert advice on system coordination, our team is ready to assist.

Contact Our Engineering Team today to discuss your project requirements.

Reduce downtime with expert diagnostics. This technical guide identifies the top 10 root causes of vacuum contactor failure—from bellows leakage to coil burnout—and provides verified maintenance solutions.

Download Troubleshooting Guide