Need Full Specifications?

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

Vacuum vs air contactor: Upgrading to JCZ vacuum contactors boosts mining safety, reduces fire risk, and cuts downtime for fast, reliable operations.

You face real risks in mining operations every day. A single equipment failure can put your team in danger and slow down production. When you compare vacuum vs air contactor, you see how quickly you can improve safety. Upgrading to a reliable vacuum contactor gives you faster response times and reduces operational hazards. This change helps you protect your workers and your business without delay.

Upgrading to JCZ vacuum contactors enhances safety by sealing arcs in a vacuum, reducing fire risks in dusty mining environments.

The robust design of JCZ contactors ensures long service life, minimizing maintenance needs and downtime for mining operations.

JCZ vacuum contactors support high switching frequencies, allowing for efficient operation of motors and pumps without frequent breakdowns.

Installing JCZ vacuum contactors is straightforward and can be completed quickly, leading to immediate safety improvements with minimal disruption.

Choosing the right JCZ model for your specific needs boosts reliability and protects your team, making your mining site safer.

You need equipment that stands up to the tough demands of mining. The JCZ5 and JCZ1 vacuum contactors give you that confidence. The JCZ5 model handles three-phase loads and works at 7.2kV or 12kV. You can use it for high-voltage motors and transformers. The JCZ1 model is perfect for single-phase loads at 12kV. It fits well in places where space is tight, like electric locomotives or special mining equipment.

Both models use a strong frame. The vacuum interrupter and the operating mechanism come together in one unit. This design makes maintenance simple and keeps your downtime low. You get a product that lasts, even when you use it every day in harsh conditions.

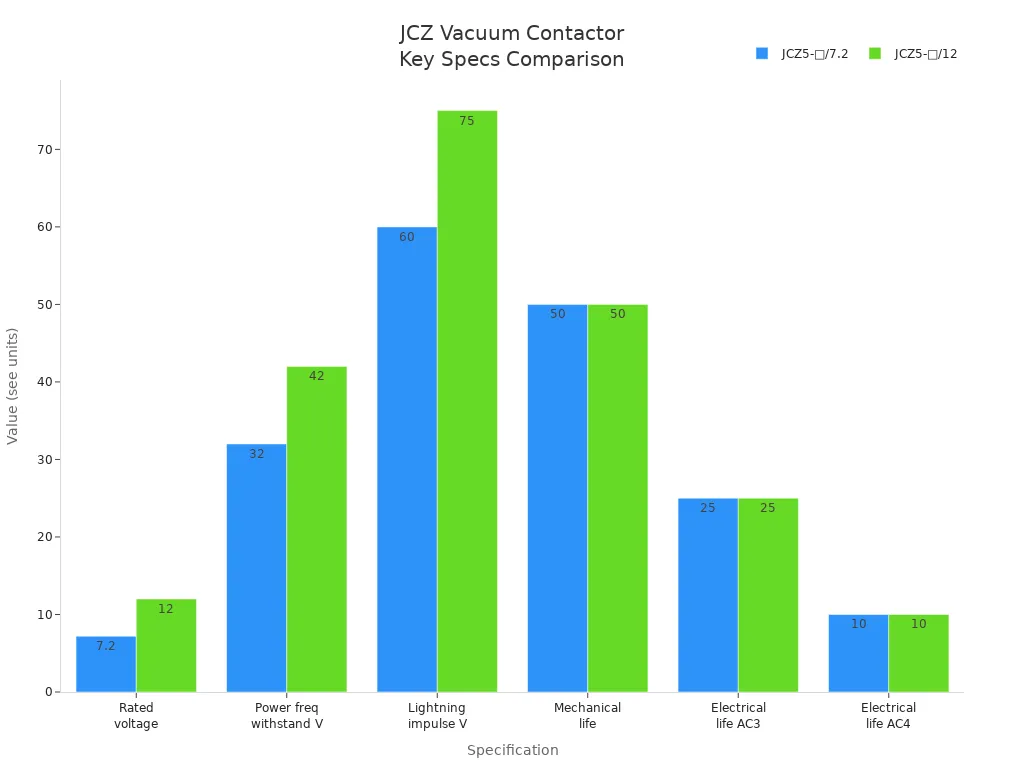

Here is a quick look at the main technical specifications for the JCZ5 series:

Item | JCZ5-□/7.2 | JCZ5-□/12 |

|---|---|---|

Rated voltage (kV) | 7.2 | 12 |

Rated current (A) | 160, 250, 400, 630 | 160, 250, 400, 630 |

Power frequency withstand voltage (1 min) (kV) | 32 | 42 |

Lightning impulse withstand voltage (kV) | 60 | 75 |

Rated breaking capacity (A) | 8Ie (25 times) | 8Ie (25 times) |

Rated closing capacity (A) | 10Ie (100 times) | 10Ie (100 times) |

Rated short-time resistance current (kA) | 10Ie (1.6~6.3) | 10Ie (1.6~6.3) |

Rated current peak tolerance (kA) | 25Ie (4~16) | 25Ie (4~16) |

Overload withstand current (kA) | 15Ie (2.4~9.45) | 15Ie (2.4~9.45) |

Mechanical life (10⁴ times) | 50 | 50 |

Electrical life (AC3 / AC4) (10⁴ times) | 25 / 10 | 25 / 10 |

You want equipment that keeps your team safe and your operations running. The JCZ vacuum contactors offer several features that make them ideal for mining:

Compact and rugged design stands up to harsh mining conditions.

Long mechanical and electrical life means fewer replacements and less downtime.

Sealed construction protects against dust and moisture, which is common in mines.

Flexible mounting options let you fit these contactors into tight spaces.

High switching frequency supports motor control centers and pump stations, where you need fast and reliable switching.

When you look at vacuum vs air contactor, you see that JCZ vacuum contactors take up less space and offer better protection. You can mount them on any plane, which helps when space is limited underground. Their strong build and sealed design keep your equipment safe from the elements.

Tip: Choosing JCZ vacuum contactors helps you reduce maintenance and improve safety in your mining operations.

When you compare vacuum vs air contactor, you see clear differences in how each one works and where you can use them. The table below shows the main distinctions:

Type | Voltage Range | Typical Applications |

|---|---|---|

Air Contactor | Low voltage (≤1kV) | General-purpose motors, lighting loads |

Vacuum Contactor | Low & Medium Voltage (>1kV) | Mining equipment, renewables, rail transit |

Vacuum contactors handle both low and medium voltage, which makes them a better fit for mining equipment. Air contactors usually work with lower voltages and general loads. You need reliable switching for heavy-duty mining tasks, and vacuum contactors deliver that performance.

You also see a big difference in arc suppression. Vacuum contactors use a sealed vacuum interrupter to control the arc. This design keeps the current flow steady until the next zero crossing, which reduces switching surges and prevents restrikes. Air contactors do not manage arcs as well, so you may face more electrical noise and equipment wear.

Many industries have switched to vacuum contactors for better reliability. For example, a U.S. automotive plant stopped monthly downtime after replacing air contactors. A wind farm in Colorado saved $150,000 each year on maintenance by using vacuum contactors for turbine switching. These real-world results show how the vacuum vs air contactor debate often ends with vacuum contactors as the clear winner for demanding environments.

Safety matters most in mining. When you look at vacuum vs air contactor, you see that vacuum contactors offer stronger protection against fire and equipment failure.

Vacuum contactors seal the arc inside a vacuum chamber. This design keeps sparks from escaping and starting fires, which is critical in mines filled with dust and gas.

The sealed construction also blocks moisture and dust from reaching the contacts. You get better performance and fewer failures, even in harsh underground conditions.

Air contactors leave the arc exposed to the air. This can let sparks escape and ignite flammable materials. You face a higher risk of fire and equipment damage.

Vacuum contactors also last longer. They have a mechanical life of about 10,000 operations, which means you replace them less often. Air contactors wear out faster because the open arc causes more damage to the contacts. In mining, where you need frequent switching, this difference means less downtime and lower costs.

You want equipment that works reliably with little maintenance. Vacuum contactors meet this need. They stand up to tough mining environments and keep your team safe. You spend less time fixing equipment and more time keeping your operation running smoothly.

Note: Choosing vacuum contactors helps you reduce fire risk, lower maintenance needs, and improve safety for your mining team.

You want to see safety improvements right away. Vacuum contactors give you that advantage. When you install a JCZ vacuum contactor, you get instant arc suppression. The sealed vacuum interrupter traps the arc inside. This stops sparks from escaping and keeps your equipment safe. You lower the risk of fire in areas with dust or gas.

You also benefit from high switching frequency. The JCZ series can handle many operations without wearing out. You can switch motors and pumps on and off as often as you need. This keeps your mining process running smoothly. You do not have to worry about frequent breakdowns or long maintenance stops.

The robust design of the JCZ contactors means you get long service life. You spend less time replacing parts. You also reduce the chance of sudden failures that can put your team at risk. The sealed construction blocks dust and moisture. Your equipment stays clean and works reliably, even in tough underground conditions.

Tip: You can boost safety and cut downtime by choosing vacuum contactors for your mining site.

You see the difference between vacuum vs air contactor when you look at real mining operations. In a coal mine, dust fills the air. An air contactor can let sparks escape and start a fire. A vacuum contactor keeps the arc sealed. You protect your workers and your equipment.

In a gold mine, you need to switch pumps and fans many times each day. The JCZ5 vacuum contactor handles this high switching frequency with ease. You do not have to stop for repairs as often. Your production stays on track.

A copper mine faces wet and dirty conditions. The JCZ1 vacuum contactor has a sealed frame. It blocks moisture and dust. You get reliable performance, even when the environment is harsh.

Mining companies that switch to vacuum contactors report fewer equipment failures. They see less downtime and lower maintenance costs. You can achieve these results by upgrading your contactors. You give your team a safer place to work and keep your operation running strong.

Note: Real mines trust JCZ vacuum contactors for fast, reliable safety gains in the most demanding environments.

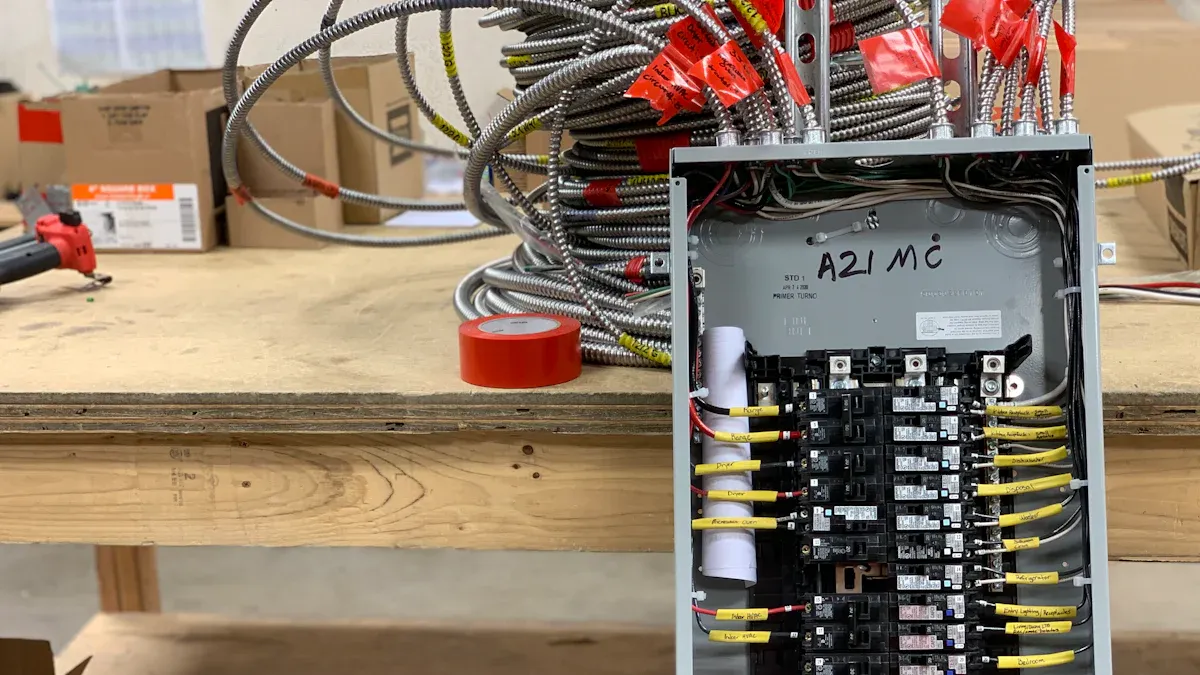

You can upgrade your mining site to JCZ vacuum contactors with a clear, step-by-step approach. This process helps you minimize downtime and ensures a smooth transition.

Assess Your Current System

Start by reviewing your existing air contactors. Identify all locations and equipment that use them.

Select the Right JCZ Model

Choose between the JCZ5 for three-phase loads and the JCZ1 for single-phase applications. Match the voltage and current ratings to your equipment.

Plan the Installation

Schedule the upgrade during planned maintenance windows. Prepare your team with the necessary training and safety procedures.

Remove Old Air Contactors

Disconnect power and safely remove the air contactors. Inspect wiring and terminals for wear or damage.

Install JCZ Vacuum Contactors

Mount the new contactors using the flexible options provided. Connect wiring according to the manufacturer’s guidelines.

Test and Commission

Power up the system and perform operational tests. Confirm that all functions work as expected.

Tip: Keep spare JCZ contactors on hand for quick replacements in the future.

You can complete most upgrades within a single maintenance shift. The compact design of JCZ contactors speeds up installation. Your team will notice immediate improvements in safety and reliability.

Step | Estimated Time | Impact on Operations |

|---|---|---|

Assessment | 1-2 hours | No disruption |

Removal & Install | 2-4 hours | Minimal downtime |

Testing | 1 hour | Fast return to service |

You will see reduced fire risk and fewer equipment failures right away. Your maintenance team will spend less time on repairs. Production interruptions will decrease. Workers will feel safer, and your operation will run more smoothly.

Note: Upgrading to JCZ vacuum contactors gives you fast, measurable safety gains with minimal impact on your mining schedule.

You see how JCZ vacuum contactors deliver rapid safety improvements in mining. These contactors reduce fire risk and cut downtime. Quick upgrades protect your team and keep your operation running.

Review your current systems.

Choose the right JCZ model.

Schedule your upgrade.

Tip: Act now to lower risks and boost reliability. Your decision makes a safer mining site possible.

You get sealed arc chambers with JCZ vacuum contactors. This design stops sparks from escaping. You lower fire risk in dusty or gas-filled mining areas.

Yes. The compact design lets you fit JCZ contactors in small panels or crowded control rooms. You save space without losing performance.

You spend less time on maintenance. The sealed construction keeps dust and moisture out. You check connections and operation during routine inspections.

Absolutely. You can switch motors and pumps on and off many times each day. The JCZ series handles frequent operations without wearing out fast.

Model | Voltage Range |

|---|---|

JCZ5 | 7.2kV, 12kV |

JCZ1 | 12kV |