Need Full Specifications?

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

A vacuum switch monitors vacuum levels and activates or deactivates equipment when a set pressure threshold is reached, ensuring system safety.

A vacuum switch allows you to control and monitor vacuum systems by activating or deactivating equipment when a specific pressure threshold is reached. You rely on this device to maintain safe and efficient operation in demanding environments.

Feature | Description |

|---|---|

Advanced Vacuum Interruption Technology | Ensures arc-free switching, minimizing contact wear and reducing inrush currents. |

High Reliability and Safety | Compliant with IEC and ANSI standards, designed for safe performance in harsh environments. |

Compact and Low-Maintenance Design | Eliminates the need for gas or oil, reducing lifecycle costs and maintenance requirements. |

A vacuum switch controls equipment by activating or deactivating it when a specific vacuum pressure is reached, ensuring safe operation.

Choose between mechanical and electronic vacuum switches based on your needs; mechanical switches offer durability, while electronic switches provide higher accuracy.

Regular maintenance and proper installation of vacuum switches extend their lifespan and prevent unexpected failures.

Integrating vacuum switches with power tools enhances safety and efficiency by automating dust collection during operation.

Consider factors like media compatibility and environmental conditions when selecting a vacuum switch for your application.

You use a vacuum switch to monitor and control systems that operate under reduced pressure conditions. This device detects when the pressure inside a chamber or pipeline drops below a set threshold. You rely on it to activate or deactivate equipment, ensuring that your system maintains optimal performance and safety.

A vacuum switch operates based on several fundamental principles:

Vacuum acts as a medium to extinguish electrical arcs during current interruption.

The absence of free electrons in a vacuum allows the arc to extinguish quickly at the next current zero.

When contacts open, the arc forms due to free electrons around the contacts, which ionize under voltage pressure.

In a vacuum, the arc cannot sustain because there are no free electrons, so it extinguishes rapidly.

The rate of rise of recovery voltage (RRRV) is managed effectively in a vacuum, preventing the arc from reigniting.

You find vacuum switches in applications that require detection of pressures below atmospheric pressure, which is defined as 0 bar (absolute). These switches work in environments such as vacuum chambers and vacuum pumps. Sensors in these devices can measure pressures down to a few millibars or even microbars, making them suitable for precise control in scientific and industrial settings.

The main function of a vacuum switch is to sense changes in vacuum and respond by switching electrical contacts. You use this capability to automate processes, protect equipment, and maintain system integrity. When the vacuum reaches a preset level, the switch triggers an action, such as turning on a pump or shutting down a system to prevent damage.

You can choose between mechanical and electronic vacuum switches depending on your requirements. Each type offers distinct advantages:

Feature | Mechanical Switches | Electronic Switches |

|---|---|---|

Reliability | More reliable under pressure surges | Lower reliability under overpressure |

Accuracy | Generally lower accuracy (2% typical) | Higher accuracy (0.25% to 2%) |

Proof Pressure Ratings | Higher proof pressure ratings | Lower proof pressure ratings |

Adjustability | Factory setting or user-adjustable | Adjustable setpoint with dials or keypad |

Application Suitability | Suitable for a wide range of pressures | Best for applications requiring high accuracy |

You select a vacuum pressure switch when you need precise control over low-pressure environments. Mechanical switches offer durability and reliability, especially in systems with frequent pressure surges. Electronic switches provide higher accuracy and easier adjustability, making them ideal for applications that demand tight pressure control.

Tip: Always match the type of vacuum switch to your system’s pressure range and accuracy needs. This ensures reliable operation and extends the lifespan of your equipment.

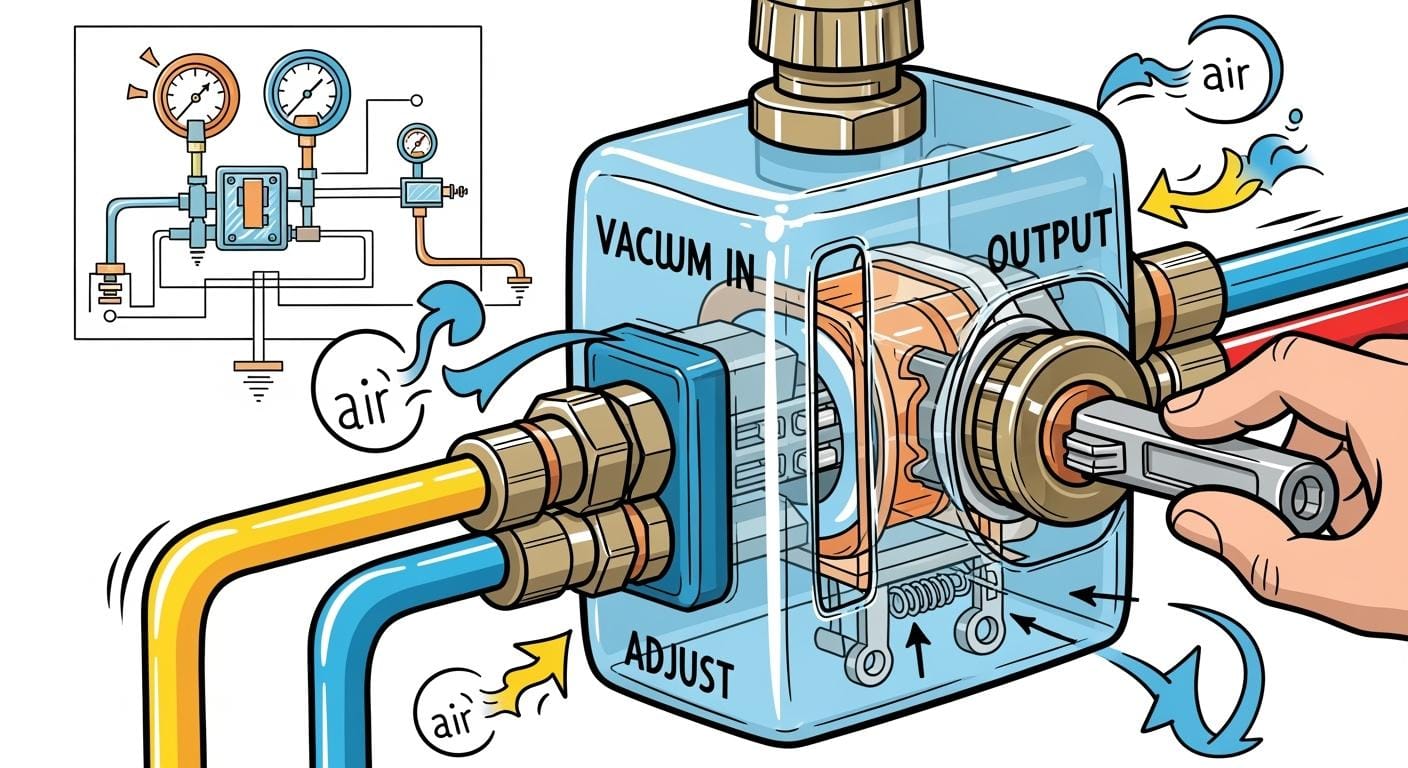

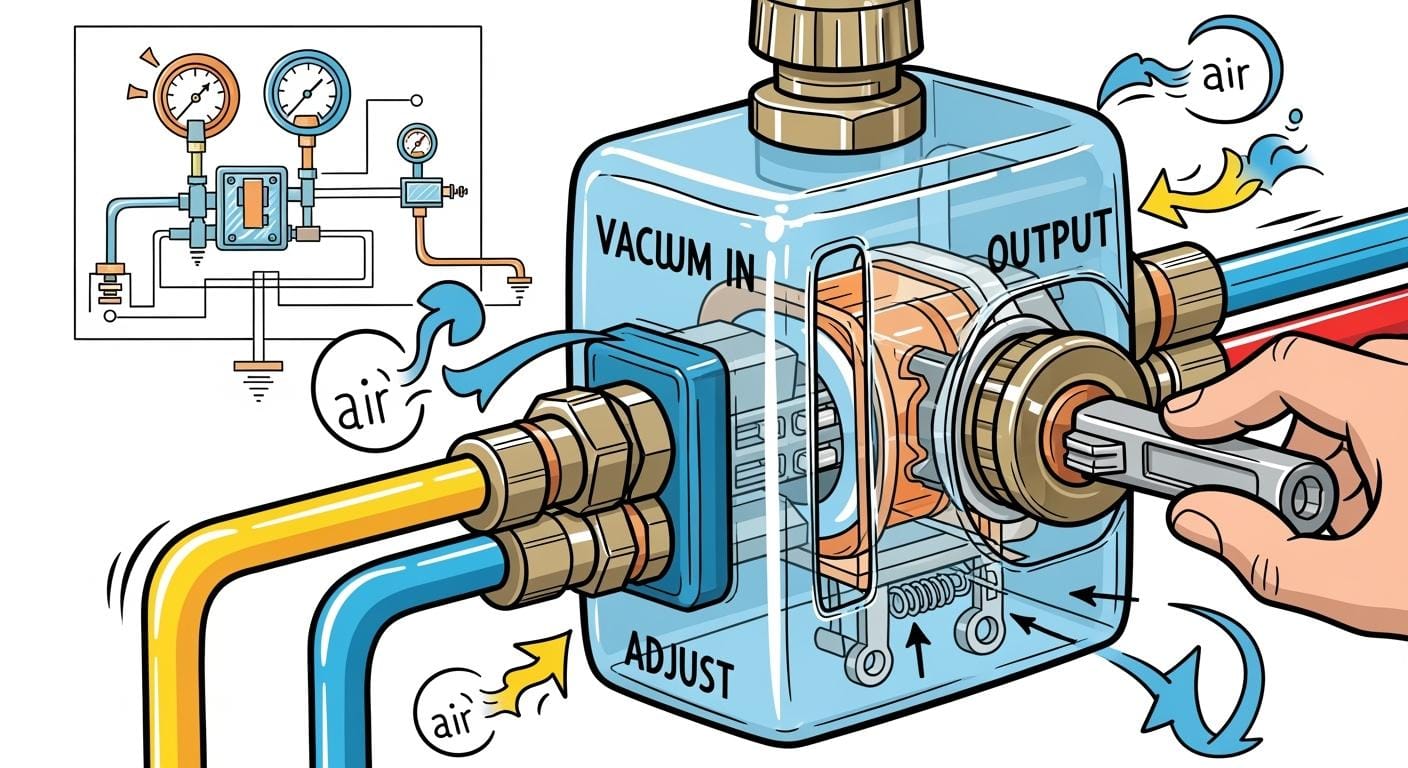

You rely on a vacuum switch to monitor the vacuum level in your system and respond when the pressure reaches a specific setpoint. The operation begins when the vacuum inside a chamber or pipeline changes. As the vacuum increases or decreases, the internal sensing element—often a diaphragm or bellows—moves in response to the pressure difference. This movement triggers the switch mechanism.

Here is a step-by-step overview of how a vacuum switch operates:

The system creates a vacuum, reducing the air pressure inside the monitored space.

The sensing element inside the vacuum switch detects the change in pressure.

When the vacuum reaches the preset threshold, the sensing element moves enough to actuate the switch contacts.

The switch either opens or closes an electrical circuit, depending on your system’s requirements.

This action starts or stops connected equipment, such as a vacuum pump or safety alarm.

You benefit from this automatic response because it helps maintain safe and efficient operation. The switch prevents equipment from running under unsafe conditions or outside optimal vacuum levels.

To keep your vacuum switch working reliably, you should follow best practices for installation and maintenance. Proper installation ensures correct alignment and secure connections, which prevents leaks and overheating. Regular maintenance, such as routine inspections, cleaning, and timely replacement of worn parts, helps avoid contamination and mechanical failure. You also need to follow usage guidelines, including operating within recommended parameters and protecting your pump from damaging substances.

Note: Routine care and correct installation extend the life of your vacuum switch and reduce the risk of unexpected failures.

You can choose between two main types of vacuum switches: mechanical and electronic. Each type offers unique advantages for different applications.

Mechanical Vacuum Switches

Mechanical switches use physical components like diaphragms, springs, and levers to sense vacuum and actuate the contacts. You often select these switches for their durability and ability to handle pressure surges. They work well in environments where reliability is more important than high accuracy. Mechanical switches usually have a fixed hysteresis, which means the difference between the activation and deactivation points remains constant. This feature prevents rapid cycling and protects your equipment from unnecessary wear.

Electronic Vacuum Switches

Electronic switches use sensors and electronic circuits to detect vacuum levels and control switching. You benefit from higher accuracy and easier adjustability with these devices. Many electronic switches allow you to set the activation point using a dial or keypad. They are ideal for applications that require precise pressure control. Electronic switches may offer adjustable hysteresis, giving you more flexibility in system design.

Type | Key Features | Best Use Case |

|---|---|---|

Mechanical Vacuum Switch | Durable, handles surges, fixed hysteresis | Industrial systems, basic automation |

Electronic Vacuum Switch | High accuracy, adjustable, flexible hysteresis | Laboratory, process control |

You should match the type of vacuum switch to your system’s needs. Mechanical switches provide robust performance in tough environments. Electronic switches deliver precision and flexibility for advanced applications.

You depend on several key components to ensure your vacuum switch operates reliably in demanding environments. Each part plays a specific role in monitoring and controlling vacuum and pressure levels. The table below outlines the main components and their functions:

Component | Function |

|---|---|

Robust sensors | The VRP uses a Pirani filament, while the VRC features a chemically resistant ceramic sensor. |

Switch point setting | You can adjust the switch point over the entire range using a potentiometer. |

High protection class | The metal housing with IP54 protection resists dust and splash water. |

You benefit from robust sensors that provide accurate detection of vacuum changes. The adjustable switch point lets you fine-tune the device for your specific application. The high protection class ensures your vacuum switch withstands harsh conditions, extending its service life.

High-quality vacuum switches deliver performance advantages that set them apart from standard models. You gain precise control over vacuum and pressure, which is essential for process stability and equipment safety. The following table highlights the most important performance features:

Feature | Description |

|---|---|

Precision | High-quality vacuum switches offer precise measurements and control. |

Reliability | Designed for consistent performance over time. |

Safety | Enhanced safety features prevent failures and hazards. |

High Product Life Cycle | Longer operational lifespan than standard models. |

Diaphragm Seal Designs | Multiple designs for different applications. |

Extensive Pressure Range | Operates across a wide range of pressures. |

High Repeatability | Delivers consistent performance with minimal variation. |

Low Hysteresis | Reduces the gap between set point and actual pressure. |

Certifications | Meets international standards such as CE, ATEX, and GOST. |

You also need to consider response time and switching accuracy. For example, Potence Controls Model 1 provides 0.5% accuracy of the full range span and a fast response time of 16.7Hz. These features help you maintain precise vacuum control and quick system response.

Tip: Choose a vacuum switch with the right combination of features to match your application’s pressure range, accuracy, and environmental demands.

You encounter vacuum switches in a wide range of environments. In industrial settings, you use them to control and monitor medium voltage switchgear, metal-clad switchgear, and porcelain housed circuit breakers. Each application has unique requirements for safety, reliability, and maintenance. The table below outlines common industrial uses and their specific needs:

Application Type | Specific Requirements |

|---|---|

Medium Voltage Switchgear | Minimum maintenance, recognized as the most reliable current interruption technology |

Metal-Clad Switchgear | Suitable for medium voltage, ensures safety and reliability |

Porcelain Housed Circuit Breakers | Developed for higher voltage, not always commercially feasible |

You also find vacuum switches in home applications. For example, you use them in HVAC systems to maintain proper vacuum levels and in central vacuum cleaners to automate suction. In automotive repair shops, you rely on these switches for brake bleeding and air conditioning service.

When you select a vacuum switch, you must consider several factors:

Media compatibility

Working pressure and temperature

Environmental conditions, such as weather-proof or flame-proof enclosures

Output and electrical rating

Process connection and electrical entry size

You face challenges in new applications, including volatility in raw material prices, supply chain disruptions, and technical complexity. You must stay informed about these issues to maintain system efficiency and reliability.

You can dramatically improve workshop safety and efficiency by integrating a power tool and vacuum switch into your workspace. When you connect your power tool and vacuum switch, you enable hands-free dust collection. The vacuum automatically starts when you power on your tool and stops when you turn it off. This setup supports automated dust control and reduces airborne particles.

You benefit from this integration in several ways:

You increase dust collection efficiency by capturing debris at the source.

You enhance workshop safety by minimizing inhalation risks and slip hazards.

You boost efficiency by eliminating manual steps and reducing cleanup time.

You often use a power tool and vacuum switch combination with table saws, miter saws, and sanders. This pairing ensures your dust collection system operates only when needed, saving energy and extending equipment life. You also maintain a cleaner workspace, which supports better project outcomes.

Tip: For best results, choose a power tool and vacuum switch that matches your dust collection system’s capacity and your tool’s power requirements. This approach maximizes efficiency and protects your investment.

You rely on vacuum switches to maintain safe and efficient operation in vacuum systems.

A vacuum switch activates or deactivates equipment when a set vacuum pressure is reached.

You use it to relieve or increase pressure in hydraulic, pneumatic, and processing industries.

It opens or closes circuits to protect your system and ensure functionality.

Feature/Application | Key Role and Benefit |

|---|---|

Robust design, IP66 rating | Withstands harsh environments and offers reliable control |

Real-time warnings | Enables predictive maintenance and prevents major faults |

Compact sensor unit | Measures vacuum without line losses |

Vacuum switches remain essential for modern automation, diagnostics, and safety across industries.

You use a vacuum switch to detect low pressure below atmospheric levels. A pressure switch monitors higher pressures above atmospheric. Both control equipment, but each suits different system requirements.

You turn a dial or use a keypad to set the activation point. Some models offer a potentiometer for fine-tuning. Always check your manual for specific instructions.

You select models with high protection ratings, such as IP54 or IP66. These switches resist dust and water, ensuring reliable operation in harsh conditions.

You inspect the switch regularly for wear, clean contacts, and replace damaged parts. Routine checks help you prevent failures and extend service life.

You find vacuum switches in manufacturing, automotive, laboratory, and HVAC industries. These devices help you automate processes and maintain safety.