Need Full Specifications?

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

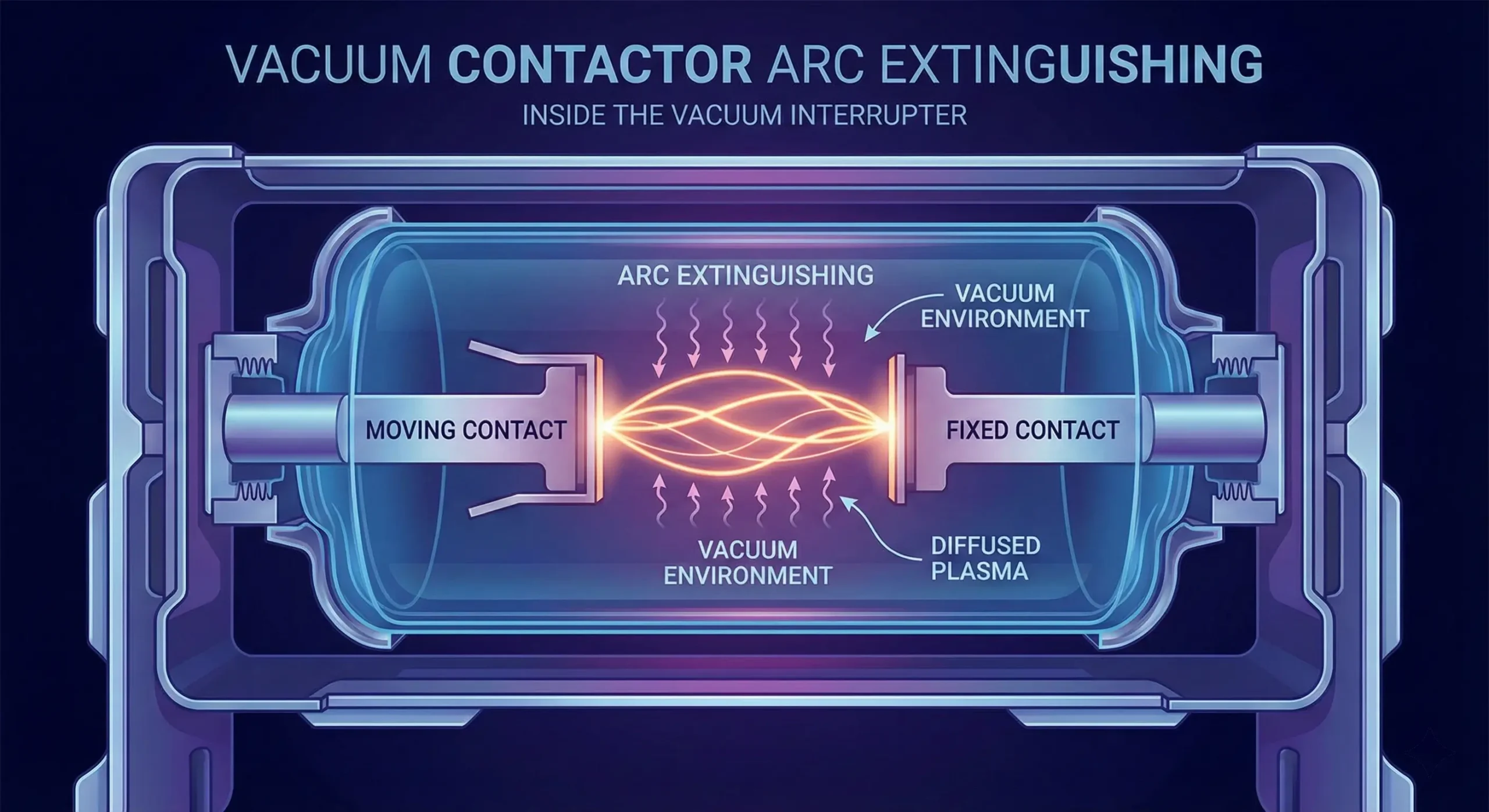

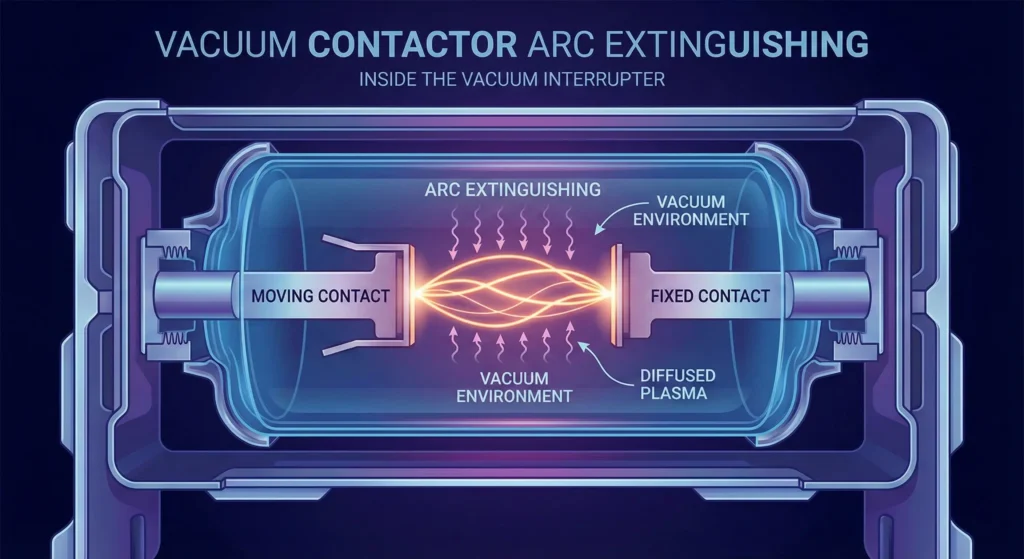

Understanding How Does a Vacuum Contactor Extinguish Arc? Inside the Vacuum Interrupter is essential for anyone working with electrical distribution, industrial motors, or high-voltage switching equipment. Arcing is a natural but dangerous phenomenon that occurs whenever electrical contacts open under load. The vacuum contactor was engineered precisely to control and extinguish this arc with remarkable speed and safety. In this article, we dive deep into how it works, why it is so reliable, and what makes vacuum interruption superior to many other arc-quenching technologies.

A vacuum contactor is an electrical switching device designed to control medium-voltage circuits, especially those driving motors, transformers, and capacitor banks. Built to handle thousands of switching operations, it provides reliable control in demanding industrial environments such as mining, manufacturing, and power distribution.

Vacuum contactors are valued for their compact design, low maintenance needs, and strong arc-quenching ability. Their performance is largely due to the technology inside their vacuum interrupters—where all switching actually takes place.

A typical vacuum contactor includes:

Each component works together to extinguish arc safely and quickly.

A vacuum interrupter is a sealed ceramic and metal chamber containing two specially designed contacts. It holds an internal pressure of about 10⁻⁵ to 10⁻⁶ torr, which is extremely close to a perfect vacuum. At this pressure, there are almost no gas molecules—meaning arcs behave differently and dissipate much faster.

The vacuum interrupter is the heart of the arc control system.

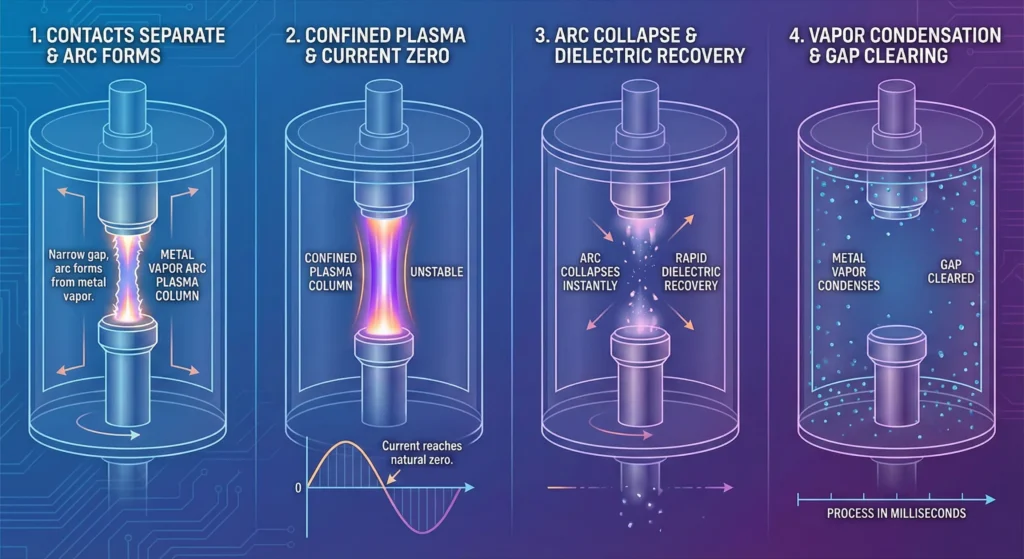

When someone asks How Does a Vacuum Contactor Extinguish Arc? Inside the Vacuum Interrupter, the answer begins with understanding how the arc forms. When the contacts pull apart under load, the current does not stop immediately. Instead, a metal vapor arc forms due to the rapid evaporation of the contact material.

Inside the vacuum, however, the arc is extremely limited and easy to extinguish.

Here’s what happens during interruption:

This entire process happens in milliseconds.

Vacuum interruption works because the dielectric strength in a vacuum recovers extremely quickly once the current reaches zero. Unlike air or gas, where ionized particles may linger, a vacuum removes the possibility of maintaining arc continuity.

A clean environment inside the interrupter ensures reliable reinsulation between contacts.

The arc in a vacuum is sustained not by surrounding air (because there is none) but by vaporized contact material. When the current drops to zero, the vapor condenses almost instantly, leaving nothing to support re-ignition.

This property makes vacuum interruption highly self-healing and incredibly efficient.

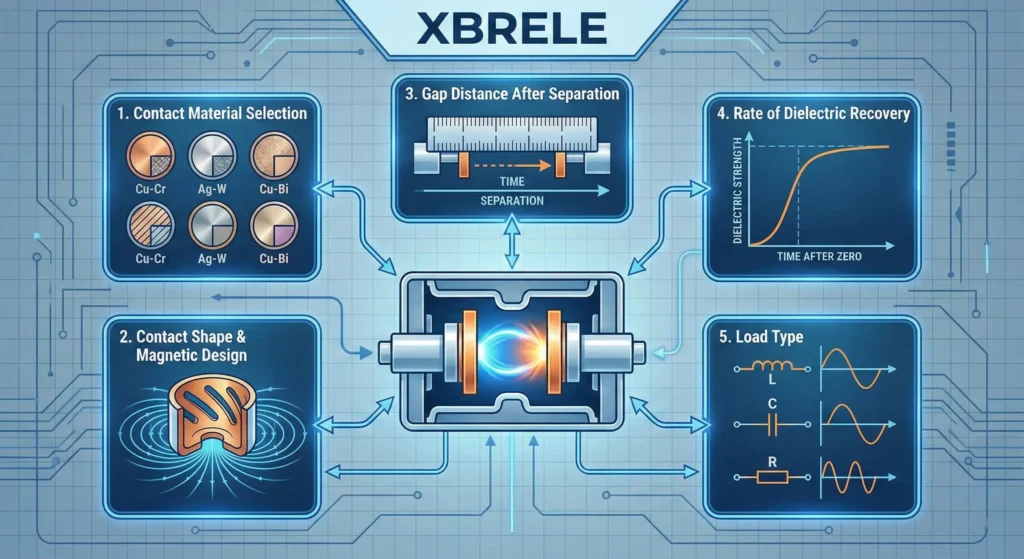

Arc interruption depends on several engineering considerations. Even though vacuum interrupters are highly reliable, their performance is influenced by:

Each factor contributes to the interrupter’s long-term reliability.

Most vacuum interrupters use copper-chromium alloy contacts. These materials offer:

Copper-chromium allows the system to interrupt large currents with minimal damage to the electrodes.

Dielectric recovery is the process of restoring insulation between separating contacts. For successful interruption, the medium must withstand voltage before the next half-cycle. Vacuum excels at this because:

This is why vacuum contactors have such long service lives.

Some key advantages include:

Vacuum contactors remain one of the best solutions for medium-voltage applications.

| Feature | Vacuum Interrupter | Air-Break Contactor |

|---|---|---|

| Arc Size | Very small | Large, visible |

| Maintenance | Low | Higher |

| Dielectric Recovery | Very fast | Moderate |

| Life Cycle | Long | Shorter |

| Environment Impact | No harmful gases | Air ionization byproducts |

Vacuum clearly outperforms air-break devices for demanding applications.

You’ll find vacuum contactors widely used in:

They offer dependable switching where safety and reliability are critical.

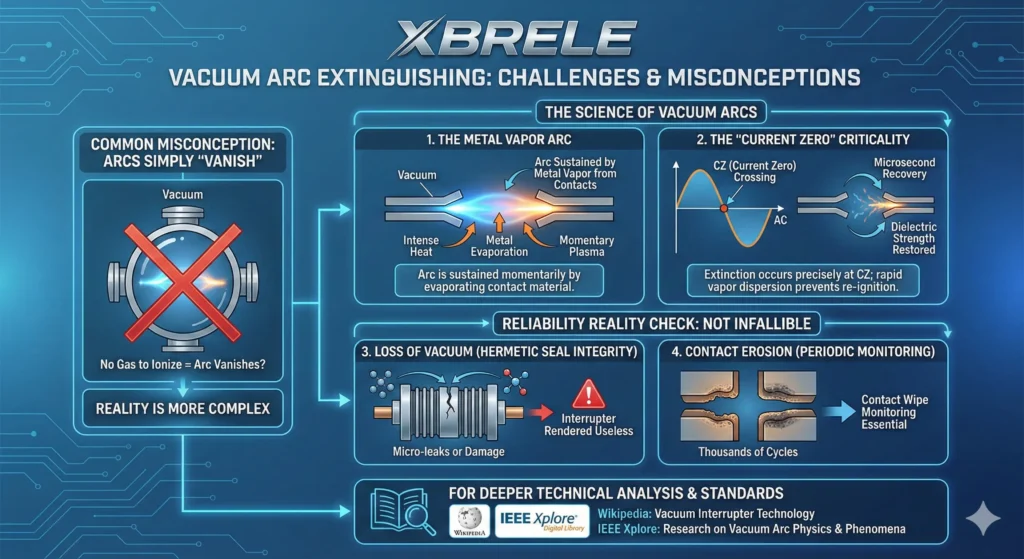

A prevalent misunderstanding in high-voltage engineering is that arcs simply “vanish” because they are in a vacuum. The physics are far more complex and fascinating:

Reliability Reality Check While Vacuum Interrupters (VIs) are renowned for their “fit-and-forget” durability, the myth that they are infallible is dangerous.

For deeper technical analysis and industry standards, refer to the following authoritative resources:

Wikipedia: Vacuum Interrupter Technology (A comprehensive overview of construction, operation, and historical development.)

IEEE Xplore Digital Library: Research on Vacuum Arc Physics & Phenomena (Access peer-reviewed papers on arc control and vacuum insulation technology.)

1. Does a vacuum completely prevent arc formation?

No. Arcs still occur but are smaller and easier to extinguish.

2. Why does the arc disappear at current zero?

Because the vacuum cannot sustain ionization once metal vapor collapses.

3. What pressure is needed inside a vacuum interrupter?

Typically between 10⁻⁵ and 10⁻⁶ torr.

4. How long does arc interruption take?

Just a few milliseconds.

5. Can vacuum contactors switch high inductive loads?

Yes, but they require specially designed contact materials and geometries.

6. What makes vacuum technology safer?

There is no oxygen and very little vapor to support combustion or sustained arcing.

Understanding How Does a Vacuum Contactor Extinguish Arc? Inside the Vacuum Interrupter gives engineers and technicians a clearer picture of why vacuum technology dominates modern switching systems. With superior arc control, fast dielectric recovery, and exceptional durability, vacuum contactors continue to be one of the most trusted solutions in medium-voltage applications.