Need Full Specifications?

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

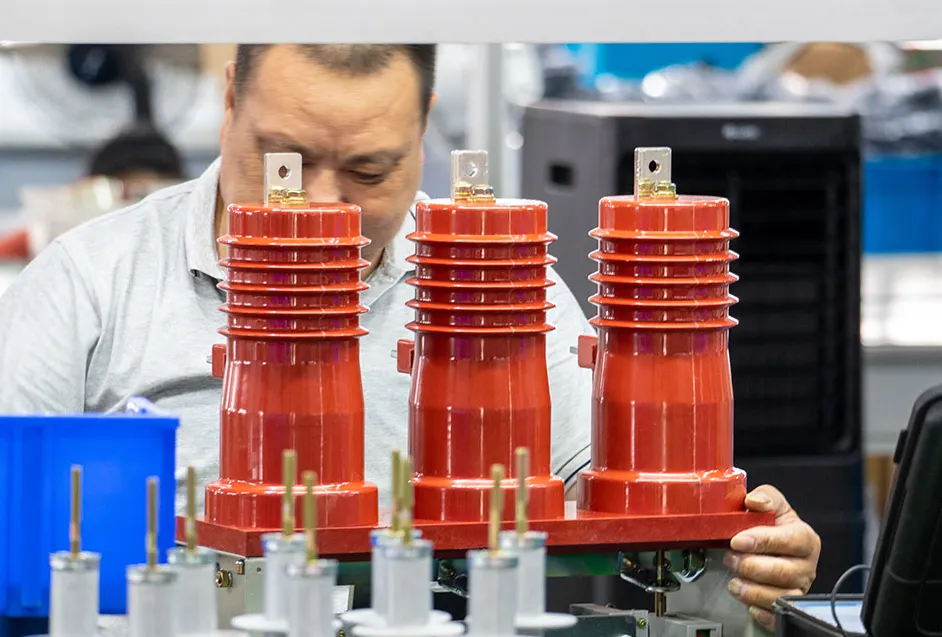

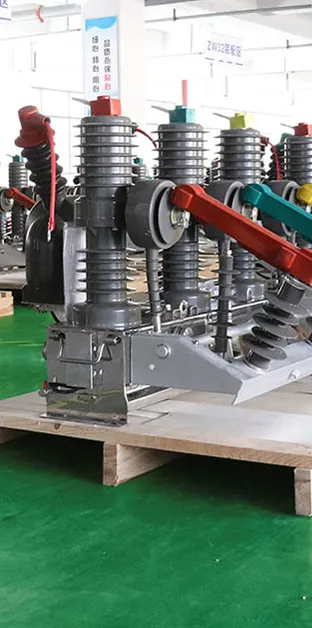

XBRele manufactures precision-engineered components for medium- and high-voltage switchgear and power distribution systems — including vacuum circuit breaker components, embedded poles, insulation parts, copper conductors and contact modules. Our factory integrates engineering, production and testing to ensure industrial-grade reliability for OEM partners worldwide.

Who We Serve

🏭 Engineering-Grade Components for MV/HV Switchgear

We manufacture core components used in 12 kV / 17.5 kV / 24 kV switchgear, ensuring mechanical strength, dielectric reliability, and long-term stability under demanding electrical conditions.

🧪Tested According to IEC HV Standards

Every batch undergoes dielectric, mechanical and insulation testing, supported by full documentation. This ensures compatibility with VCB mechanisms, AIS panels, and GIS-derived applications.

📦 OEM & Export-Ready Workflow

Our workflow supports OEM customization, drawing verification, labeling, palletized packaging, and complete export documentation — enabling efficient delivery to major markets including Asia, Europe, India, and Russia.

Our Story

2016 – Started producing molded insulation parts and basic MV switchgear components.

2019 – Added production lines for embedded poles, copper conductors, and VCB-related parts.

2022 – Implemented full dielectric, mechanical, and insulation testing aligned with IEC MV/HV standards.

2025 – Enhanced OEM workflow with engineering review, drawing validation, batch traceability, and global export documentation.

XBR Ele provides engineered components for medium- and high-voltage switchgear, supporting OEM manufacturers with reliable quality and efficient coordination.

Our production workflow, testing process, and export documentation are designed for VCB assembly plants and switchgear factories worldwide.

🏭 Integrated Manufacturing for MV/HV Components

We produce embedded poles, insulation parts, copper conductors, and VCB components in-house to ensure dimensional accuracy, stable materials, and OEM-grade consistency.

🎨 IEC-Aligned Quality & Electrical Testing

Each batch is checked with dielectric tests, mechanical checks, insulation verification, and QC documentation — ensuring compatibility with 12/17.5/24 kV switchgear systems.

📦 Export-Ready Documentation & Traceability

We support drawing verification, labeling, serial tracking, carton/pallet packaging, and full export documentation (HS codes, test reports, packing lists) for smooth global delivery.

🔁 Reliable Supply for Manufacturers

We work closely with switchgear engineering teams, providing fast communication, drawing review, material advice, and long-term supply stability for global projects.

Our Facilities

XBRELE Global Service Network

Global Delivery

Meet Our Team

Find quick answers about our embedded poles, insulation parts, copper conductors, and MV/HV switchgear components.

XBR Ele supplies embedded poles, epoxy-molded insulation parts, copper conductors, contacts, and other medium- and high-voltage switchgear components used in vacuum circuit breakers (VCB) and power distribution panels.

Yes. Our switchgear components are engineered to meet IEC requirements for insulation, dielectric strength, and mechanical endurance. We also adapt dimensions and interfaces to match OEM switchgear designs for different markets.

We support OEM partners with drawing validation, insulation and creepage design, copper conductor selection, and assembly recommendations so that new panels can be developed faster with reliable performance.

Yes. We customize pole height, creepage distance, epoxy formulation, terminal design, and copper geometry according to your MV/HV switchgear specifications, from prototypes to mass production.

Our components are used in power distribution networks, substations, industrial plants, infrastructure projects, and renewable energy systems wherever MV/HV vacuum circuit breakers and reliable insulation components are required.

Yes. We can pack embedded poles, insulation parts, copper conductors, and accessories in mixed-SKU cartons and palletized loads, with clear labels and QC photos to simplify your warehouse and production workflow.

Each batch is subject to incoming material inspection, dimensional checks, insulation and dielectric tests, mechanical endurance tests, and full batch traceability from raw materials to finished switchgear components.

Yes. We provide region-adapted embedded poles and insulation parts designed for India’s humid climate and Russia’s low-temperature conditions, as well as local VCB ratings and OEM engineering requirements.

We supply commercial invoices, packing lists, HS codes, certificate of origin, inspection reports, and other documents required for customs clearance and import into your country.

You can refer to IEC’s official publications on switchgear and controlgear at the IEC Webstore, and explore additional engineering resources on Electrical Engineering Portal (EEP).