Need Full Specifications?

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

XBRELE is an ISO9001 certified factory specializing in 12kV – 40.5kV systems. We provide a complete range of Vacuum Circuit Breakers, SF6 Switches, and Power Transformers for global panel builders and utilities.

We don’t just assemble parts; we engineer reliability. XBRELE utilizes advanced APG casting and strict quality control to deliver switchgear components that exceed IEC standards for safety and longevity.

Automated Pressure Gelation ensures void-free epoxy insulation with superior dielectric strength.

ISO9001 management system. Every batch undergoes Partial Discharge and X-Ray flaw detection.

In-house mold workshop supports rapid customization for non-standard busbar dimensions.

Components designed to fit KYN28, KYN61, and UniGear panels seamlessly.

XBRELE stands as a comprehensive Power Distribution Equipment Manufacturer, specializing in the engineering and production of core components for 12kV, 24kV, and 40.5kV networks. Unlike suppliers limited to single categories, our ISO9001-certified facility integrates four critical product lines, offering a streamlined sourcing experience for global panel builders and utility contractors.

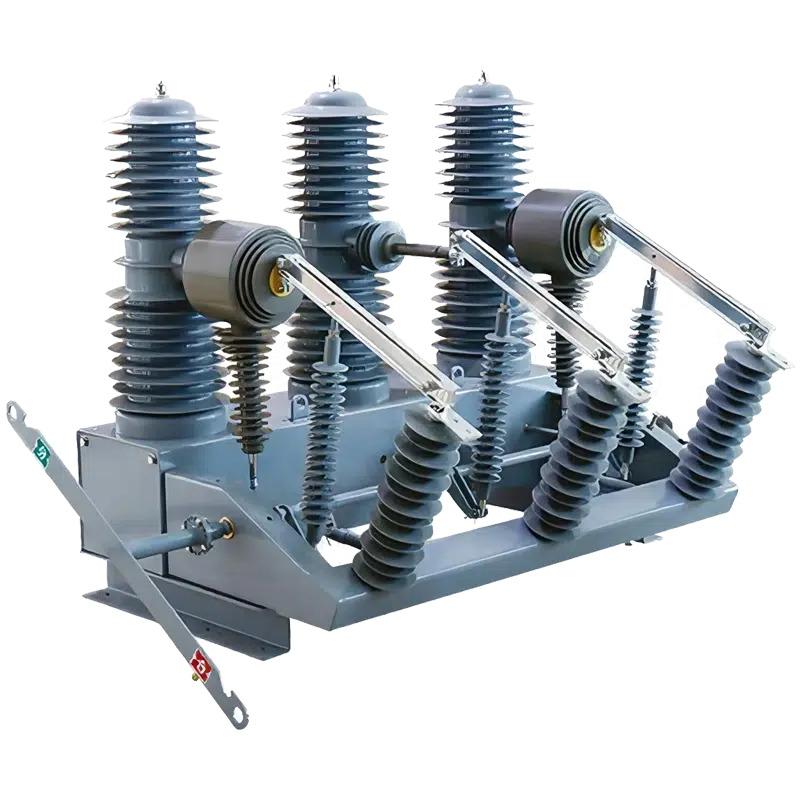

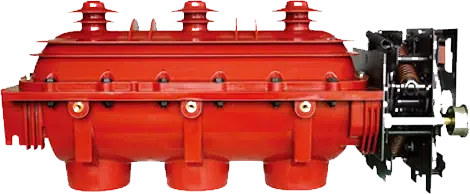

Our portfolio anchors on Vacuum Circuit Breakers (VCB), including indoor VS1 and outdoor ZW32 series, engineered for reliable fault interruption in high-voltage environments. We complement this with high-endurance Vacuum Contactors for frequent switching operations in mining and industrial motors.

Beyond switching, XBRELE manufactures essential Power Transformers, ranging from energy-efficient Amorphous Alloy types to robust Oil-Immersed units (S11/S13). To complete the switchgear ecosystem, we produce precision-molded Epoxy Insulation Components, such as Contact Boxes and Wall Bushings, using advanced APG technology. This integrated manufacturing capability positions XBRELE as a preferred partner for complete Medium Voltage transmission and distribution solutions.

Download our 2025 Product Selection Manual for full dimensional drawings and technical parameters.