Need Full Specifications?

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

Automatic circuit reclosers serve as frontline protection devices across medium-voltage distribution networks, detecting faults, interrupting current, and restoring service through programmed reclose sequences. For procurement teams and utility engineers, selecting the right recloser manufacturer determines whether equipment will perform reliably across a 25–30 year service life—or become a maintenance burden within the first decade.

This guide provides systematic evaluation criteria based on field experience across rural, urban, and industrial distribution systems. Rather than ranking specific brands, we focus on the technical indicators and verification methods that separate quality manufacturers from commodity suppliers.

The best recloser manufacturers demonstrate excellence in three core areas: vacuum interrupter quality, mechanism durability, and controller sophistication. These fundamentals predict field reliability far better than marketing claims or price positioning.

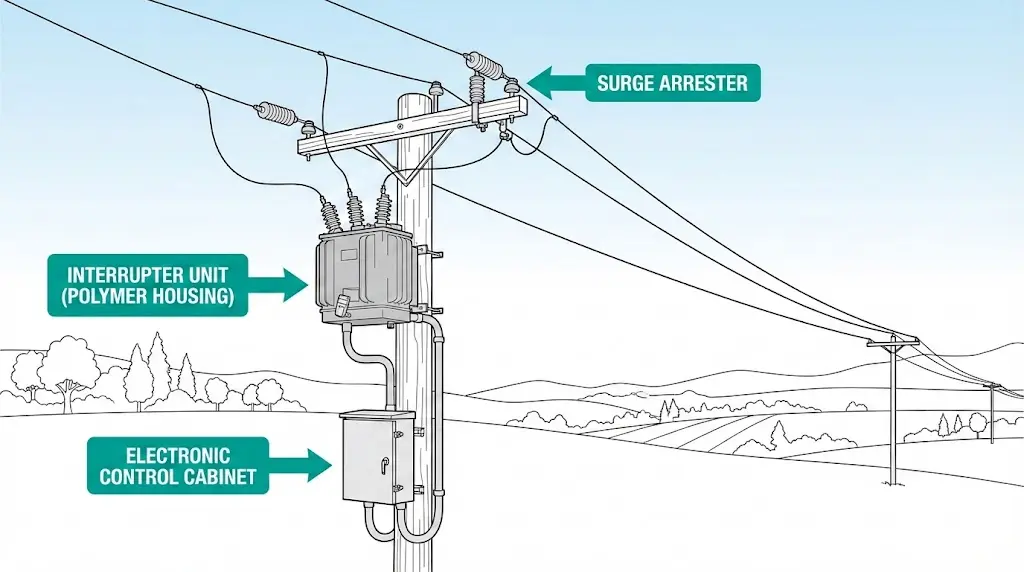

A recloser performs a deceptively simple job: detect fault current, interrupt the arc, wait through a programmed interval, reclose, and repeat until either the fault clears or the unit locks out. Behind that sequence sits technology that separates reliable equipment from hardware destined for premature failure.

Interruption medium matters first. Vacuum interrupters now dominate new recloser designs, displacing SF₆ due to environmental regulations and reduced maintenance requirements. Quality manufacturers either produce vacuum interrupters in-house or source from established suppliers with documented quality systems. Contact material—typically CuCr25 copper-chromium alloy—must meet consistent metallurgical specifications ensuring predictable arc erosion across thousands of operations.

Mechanism endurance defines long-term reliability. Reputable manufacturers publish operation counts from type testing: expect 10,000 to 30,000 close-open cycles at rated current depending on product class. Units destined for frequent switching duty require the higher end of this range. Magnetic actuator designs have largely replaced spring-stored-energy mechanisms in modern vacuum circuit breaker and recloser platforms, offering faster operation (30–50 ms) with fewer mechanical wear components.

Controller sophistication separates basic protection from distribution automation capability. Hydraulic controls still exist in legacy fleets, but microprocessor-based controllers with programmable protection curves and communication protocol support (DNP3.0, IEC 61850) represent the current standard for utility-grade equipment.

Field failure patterns trace back to these fundamentals. Vacuum interrupter leaks, contact welding from substandard materials, and mechanism fatigue account for most recloser failures—all preventable through proper manufacturer selection.

This checklist distills evaluation criteria into actionable verification steps. Each point includes what to request from manufacturers and warning signs indicating potential quality issues.

1. Interrupting Medium and Fault Current Rating

Vacuum technology is preferred for new installations. Match the kA interrupting rating to your system fault study plus a 20% safety margin. A 12.5 kA unit may suffice for rural feeders; urban substations often require 16 kA capacity.

2. Control System and Communication Protocols

Verify compatibility with your SCADA infrastructure. DNP3.0 remains widely deployed; IEC 61850 is increasingly required for smart grid integration. Request protocol conformance test certificates, not just datasheet claims.

3. Operating Sequence Programmability

Standard configurations allow 1-fast + 3-delayed trips before lockout. Confirm adjustable reclose intervals spanning 0.5 s to 180 s. The protection curve library should include IEC 60255 and IEEE C37.112 characteristics.

4. Insulation Coordination

BIL ratings must match voltage class: 95 kV for 15 kV systems, 125 kV for 27 kV, and 150 kV for 38 kV applications. Verify creepage distance meets IEC 60815 requirements for your pollution severity level.

5. Mechanical Endurance Certification

Request type test certificates per IEC 62271-111 or IEEE C37.60 from an accredited laboratory. Minimum acceptable benchmark: 10,000 CO operations at rated current with documented contact erosion data.

6. Power Supply Configuration

Self-powered units draw energy from line CTs but require minimum load current—typically around 5 A primary. External supply options (120/240 VAC, 48 VDC) provide flexibility but add installation complexity. Confirm battery backup duration for communication continuity during outages.

7. Environmental and Enclosure Ratings

Operating temperature range should span –40°C to +55°C for most applications. Control cabinet IP rating of IP55 minimum applies for outdoor installations. Coastal deployments require documented salt fog and UV resistance testing.

8. After-Sales and Spare Parts Commitment

Vacuum interrupters require replacement at 15–20 year intervals or upon reaching fault duty limits. Confirm the manufacturer’s firmware update policy and regional service network presence. Absence of clear obsolescence management indicates potential long-term support risk.

[Expert Insight: Procurement Due Diligence]

- Request X-ray inspection records for vacuum interrupter weld integrity

- Verify contact erosion curves showing expected wear per fault interruption

- Ask for reference installations operating in similar environmental conditions

- Confirm controller hardware component availability commitment (≥15 years)

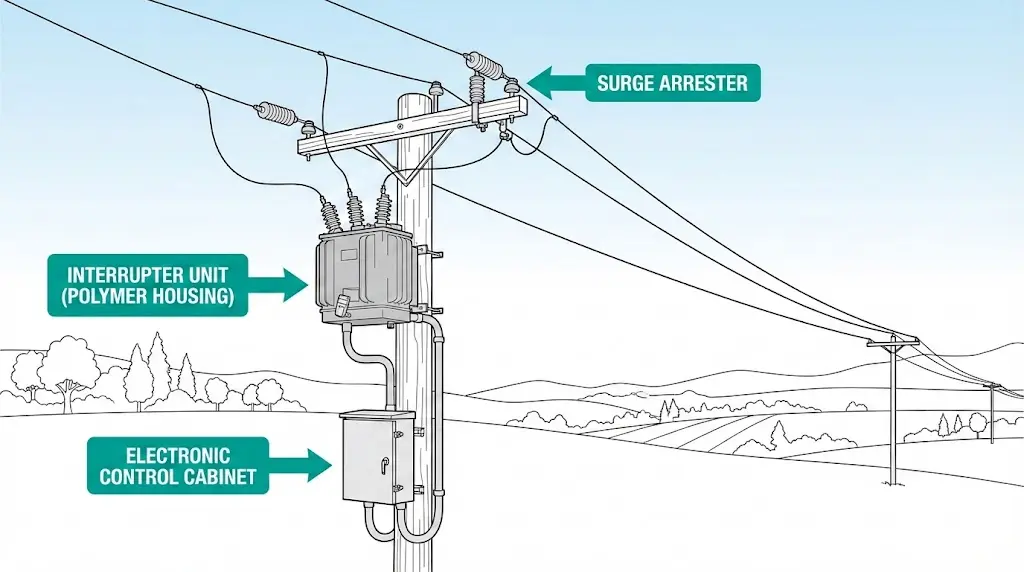

Recloser specifications must align with actual operating environments. A unit optimized for temperate suburban feeders will underperform in high-altitude mining operations or coastal industrial facilities. These four deployment scenarios illustrate how environmental factors drive specification requirements.

Scenario A: Rural Overhead Distribution (Pole-Mounted)

Long feeders exceeding 30 km present high lightning exposure and limited maintenance access. Self-powered vacuum reclosers with polymer housings dominate these applications. Specify extended creepage distance (≥25 mm/kV) and integrated surge arresters. Typical protection settings: 2-fast + 2-delayed operations with reclose intervals of 30/60/90 seconds. The manufacturer should demonstrate installations in similar rural networks with documented reliability data.

Scenario B: Urban Underground-to-Overhead Transition

Mixed cable and overhead feeders experience higher fault currents and require mandatory SCADA integration. Pad-mounted or substation-class reclosers with 12–16 kA interrupting ratings address these demands. Electronic or microprocessor controls with DNP3.0 capability enable remote monitoring and coordination with upstream breakers and downstream fuses. Request protocol conformance certificates specifically for your utility’s SCADA platform.

Scenario C: Industrial Plant Incoming Feeder

Motor inrush currents and sensitive process loads demand fast fault clearance with nuanced protection curves. Microprocessor controls offering multiple IEC 60255 curve selections handle these requirements. Sync-check relay integration becomes essential when paralleling sources. Event recording and power quality monitoring capabilities support root-cause analysis after disturbances. The manufacturer should offer firmware customization for plant-specific protection schemes.

Scenario D: High-Altitude or Extreme Environment

Installations above 1,000 m elevation require insulation derating per IEC 62271-1—typically 1% BIL reduction per 100 m above the reference altitude. Extreme cold (–40°C) demands mechanism lubricants rated for reduced atmospheric pressure and low temperatures. Control cabinet heaters prevent condensation damage. Enhanced creepage distances address pollution Class III or IV conditions common in mining and coastal-industrial hybrid environments. Request altitude-specific selection guidance and type test data demonstrating performance under derated conditions.

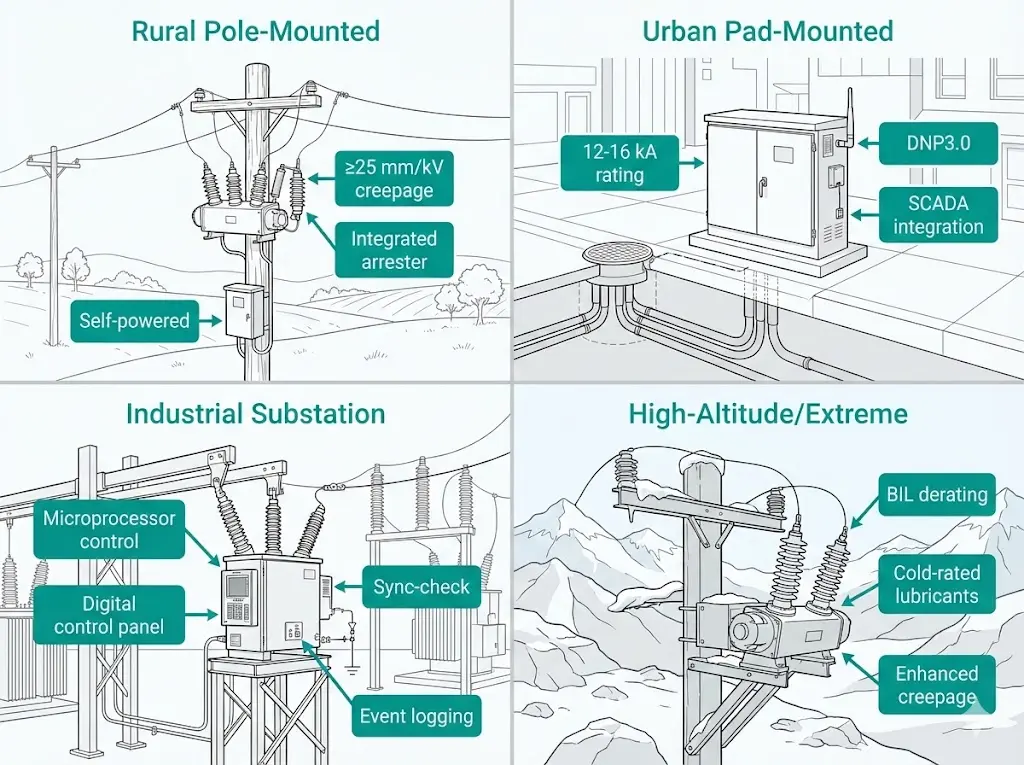

This framework applies regardless of brand, geographic origin, or price tier. Tier 1 criteria are non-negotiable; Tier 2 separates competitive manufacturers; Tier 3 identifies value-added partners.

Tier 1: Non-Negotiable Requirements

Manufacturers unable or unwilling to provide Tier 1 documentation should be disqualified regardless of price advantage.

Tier 2: Competitive Differentiators

Tier 3: Value-Added Capabilities

Red Flags Warranting Disqualification:

[Expert Insight: Type Test Verification]

- Request the test report table of contents showing clause-by-clause IEC 62271-111 compliance

- Spot-check dielectric tests (power frequency withstand, lightning impulse), short-circuit making/breaking sequences, and mechanical endurance results

- Verify the testing laboratory’s ISO 17025 accreditation status independently

Control architecture determines recloser capability, maintenance burden, and integration flexibility. Three generations coexist in operating fleets, each suited to different operational contexts.

| Control Type | Operating Principle | Advantages | Limitations | Best Application |

|---|---|---|---|---|

| Hydraulic | Oil-filled sensing, mechanical trip | No external power, proven reliability, simple troubleshooting | Limited programmability, oil maintenance required, no remote communication | Isolated rural feeders without SCADA |

| Electronic | Solid-state sensing, magnetic actuator | Programmable curves, faster operation than hydraulic | External power required, legacy protocol support only | Transitional upgrades, budget-constrained projects |

| Microprocessor | Digital relay platform, multi-protocol | Full SCADA integration, adaptive protection, IEC 61850 ready, event logging | Higher initial cost, firmware dependency, cybersecurity considerations | New smart grid installations, distribution automation |

Hydraulic reclosers remain viable for isolated feeders lacking communication infrastructure—approximately 15% of new installations in developing rural networks still specify this technology. However, microprocessor controls dominate utility-scale deployments requiring distribution automation integration.

Retrofit paths exist for fleet standardization. Hydraulic-to-electronic control upgrades extend equipment life while adding programmability, though mechanical interface compatibility requires verification with both the original equipment manufacturer and retrofit supplier. Understanding circuit breaker ratings and protection coordination principles helps ensure retrofit controllers match existing system protection schemes.

Certification documentation validates manufacturer claims through independent verification. Two primary standards govern recloser design and testing globally.

IEC 62271-111 (Automatic circuit reclosers for alternating current systems up to and including 38 kV) establishes international requirements for design, testing, and performance. This standard specifies mechanical endurance (minimum 10,000 operations), dielectric withstand levels, and short-circuit performance criteria.

IEEE C37.60 covers overhead, pad-mounted, dry-vault, and submersible automatic circuit reclosers for North American applications. While substantially aligned with IEC requirements, IEEE C37.60 includes utility-specific test protocols and environmental considerations relevant to North American grid conditions.

Verification Approach:

Request the type test report table of contents demonstrating clause-by-clause compliance. Critical test categories to spot-check include:

Regional Considerations:

North American utilities frequently require IEEE C37.60 compliance plus utility-specific amendments addressing local grid conditions. Export markets generally accept IEC 62271-111 certification, though some regions mandate additional environmental tests for salt fog exposure, solar radiation resistance, or seismic performance. [VERIFY STANDARD: Some utilities require ANSI/NETA acceptance testing post-installation as a commissioning prerequisite.]

For authoritative standard references, consult the IEC Webstore or IEEE Standards Association directly.

Initial purchase price represents only 40–60% of 25-year total cost of ownership. Procurement decisions optimizing solely for acquisition cost often result in higher lifecycle expenses.

Major TCO Components:

Self-Powered versus External Supply Economics:

Self-powered reclosers eliminate installation costs for auxiliary power supply but impose minimum load current thresholds (typically ~5 A primary). Feeders with variable loading may experience control system brownouts during low-demand periods, requiring careful load analysis before specification.

Fleet Standardization Benefits:

Common recloser platforms across a utility’s service territory reduce training requirements, simplify spare parts inventory, and enable volume procurement leverage. Evaluate manufacturer’s installed base in your region—larger fleets generally correlate with better parts availability and faster service response.

XBRELE’s engineering team brings decades of experience in vacuum interrupter technology and medium-voltage switching equipment. Our product lines—including indoor and outdoor vacuum circuit breakers and vacuum contactors—share core interruption technology with recloser platforms, providing deep technical understanding of the components that determine field reliability.

For recloser procurement projects, we offer:

Whether you’re expanding rural distribution networks, upgrading urban feeders for smart grid integration, or specifying industrial incoming protection, our team can support your evaluation process.

Contact our MV switching engineering team to discuss your recloser project requirements.

Q: How long do vacuum reclosers typically last in field service?

A: Properly maintained vacuum reclosers achieve 25–30 years of service life, with vacuum interrupter replacement typically required at 15–20 year intervals depending on switching frequency and cumulative fault duty.

Q: What minimum load current do self-powered reclosers require?

A: Most self-powered units require approximately 5 A primary current minimum to sustain control system operation through line-mounted current transformers.

Q: Can existing hydraulic reclosers be upgraded to electronic control?

A: Yes, retrofit kits allow control system upgrades while retaining the existing interrupter and mechanism assembly, though mechanical interface compatibility must be verified with both the original manufacturer and retrofit supplier.

Q: How does altitude affect recloser insulation requirements?

A: Installations above 1,000 m elevation require BIL derating—typically 1% reduction per 100 m of additional elevation—due to reduced air density affecting external insulation strength.

Q: What communication protocols should modern reclosers support for SCADA integration?

A: DNP3.0 remains the most widely deployed protocol; IEC 61850 is increasingly required for smart grid integration and substation automation applications; Modbus serves legacy SCADA systems.

Q: How many fault current interruptions can a vacuum recloser handle before interrupter replacement?

A: CuCr contacts typically withstand 20–30 full-magnitude fault current interruptions; actual service life depends on fault current magnitude relative to rated breaking capacity and cumulative contact erosion.

Q: What is the key difference between IEC 62271-111 and IEEE C37.60 standards?

A: IEC 62271-111 serves as the international standard used globally, while IEEE C37.60 addresses North American utility requirements with region-specific test protocols; both establish similar performance benchmarks through different verification approaches.