Need Full Specifications?

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

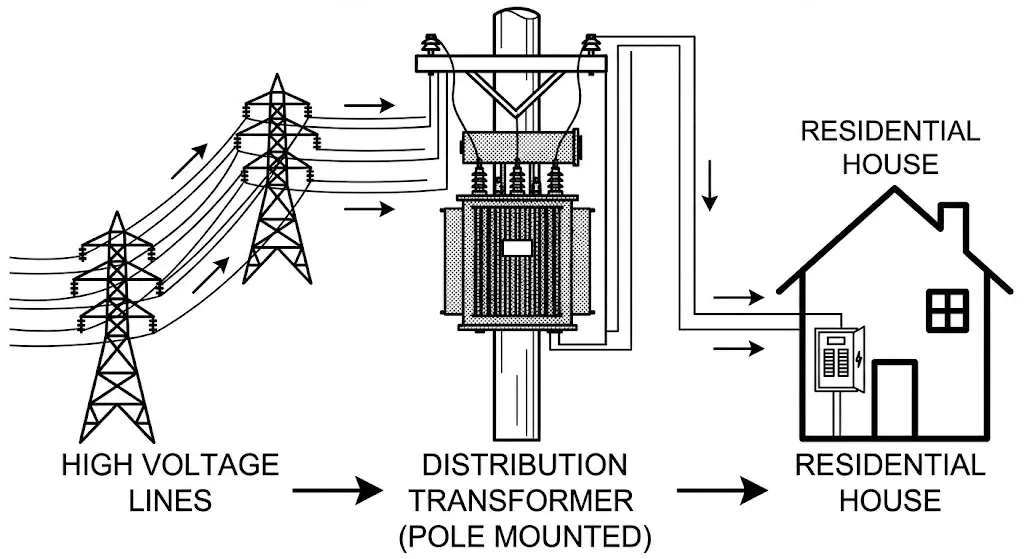

If you walk down any street or drive through an industrial park, you are never far from a distribution transformer. They are the unsung workhorses of the electrical grid, sitting quietly on poles or inside steel cabinets, performing the critical task that makes modern life possible: turning high-voltage transmission power into electricity safe enough to turn on a light switch or run a factory line.

For utility procurement managers, EPC contractors, and facility engineers, understanding the nuance of these machines—beyond just their kVA rating—is crucial. As global energy demands shift towards efficiency and renewable integration, the humble distribution transformer is evolving. It is no longer just a passive “step-down” bucket; it is a sophisticated node in the smart grid.

This guide moves past the textbook definitions to provide a practical, “in-the-field” perspective. We will cover everything from the fundamental distribution transformer function to complex sizing calculations and distribution transformer applications, ensuring you have the knowledge to make an informed purchasing decision.

Technically, a distribution transformer is a static electrical device that uses electromagnetic induction to transfer energy between two or more circuits. But in practical terms, it is the final gateway in the power delivery chain.

While transmission transformers handle massive loads (400kV and up) at substations, distribution transformers operate at the “last mile.” They typically step down medium voltages—usually 11kV, 22kV, or 33kV—to utilization voltages like 400V (three-phase) or 230V (single-phase).

Unlike generation transformers that might ramp up and down with a turbine, distribution transformers are designed for continuous duty. They must remain energized 24/7, 365 days a year, regardless of whether the load is 10% or 100%.

This operational reality drives their design philosophy:

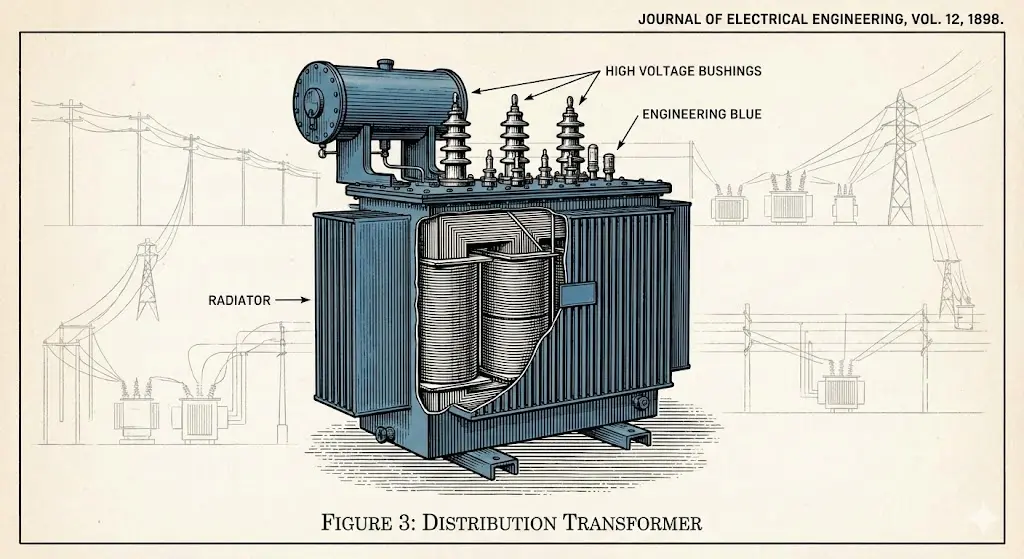

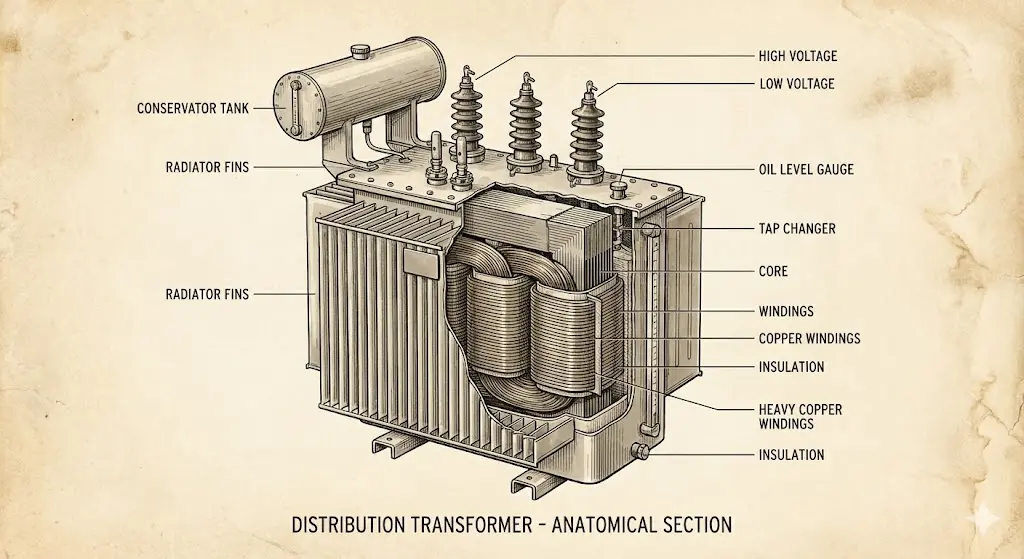

To make a smart buying decision, you need to know what’s under the tank cover. A distribution transformer isn’t a black box; it’s a system of carefully engineered components working in harmony.

The core is the heart of the unit. It creates the magnetic path for energy transfer.

This is where the electricity flows.

Often overlooked, bushings are critical. They insulate the high-voltage conductor as it passes through the grounded tank.

Heat is the enemy of a transformer. The insulation system determines the unit’s lifespan.

Where exactly are these units used? The distribution transformer applications are diverse, spanning from simple residential setups to complex industrial grids.

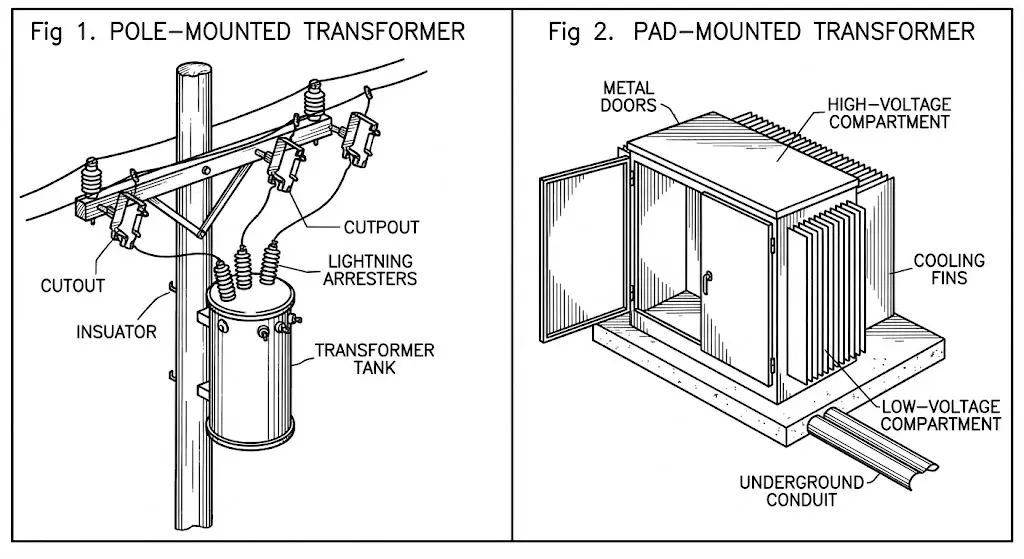

In neighborhoods, transformers step down voltage to 120/240V or 230/400V for household appliances. Reliability and safety are the top priorities here, often favoring pad-mounted units in modern subdivisions to remove unsightly overhead wires.

Factories have heavy inductive loads (motors, drives) that can introduce harmonics. Transformers here are often robustly sized to handle “dirty power” and high inrush currents. Commercial buildings often use dry-type transformers in basements to minimize fire risk.

This is a rapidly growing sector. Solar farms and wind turbines require specialized distribution transformers to step up voltage from the inverter (e.g., 800V) to the grid voltage (e.g., 33kV). These units must handle bi-directional power flow and harmonics generated by inverters.

Fast-charging stations place unique stress on transformers due to rapid load cycling (0% to 100% load in seconds). Specialized units with reinforced windings are often required to prevent mechanical fatigue.

The environment dictates the form factor. The internals might be similar, but the housing and protection radically differ.

These are the cylindrical tanks you see high up on utility poles. They are the backbone of rural and suburban electrification.

These are the green square boxes sitting on concrete pads in subdivisions, commercial parks, and underground distribution networks.

When reading a nameplate or a spec sheet, specific values determine whether the unit fits your application. Understanding the distribution transformer rating is essential to avoid under-sizing.

A transformer rated 11kV / 400V is standard. But grid voltage isn’t perfect. It fluctuates based on distance from the substation.

This cryptic code matters.

Usually 4% to 6%. This value dictates the short-circuit current limit.

It is a common error for junior engineers to confuse the two. Understanding distribution transformer vs power transformer differences is vital for procurement.

| Feature | Distribution Transformer | Power Transformer |

|---|---|---|

| Primary Function | Voltage delivery to end-user | Bulk energy transmission |

| Operating State | Always ON, load fluctuates heavily (0-100%) | Often runs near full load (80-100%) |

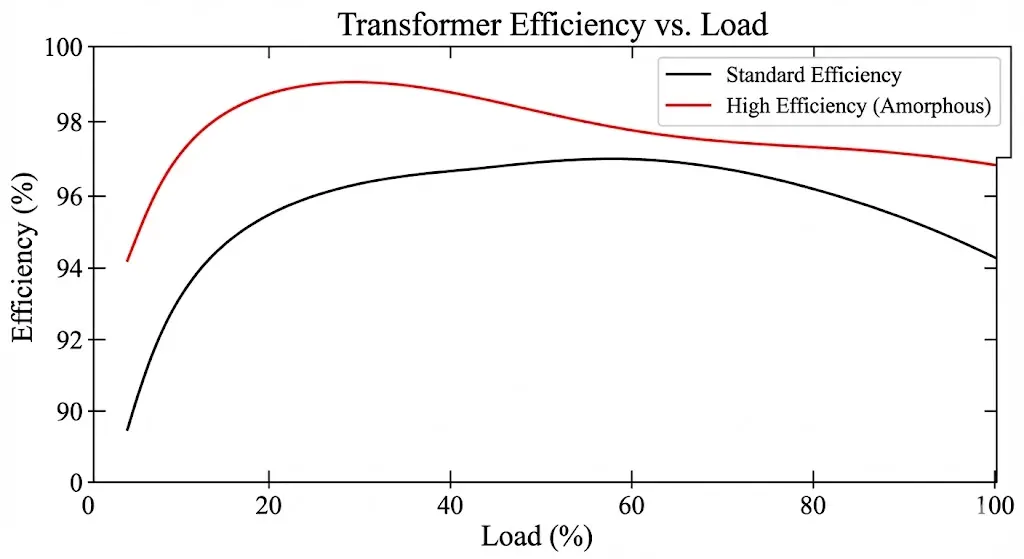

| Efficiency Design | Optimized for iron losses (Core losses) | Optimized for copper losses (Load losses) |

| Size | Small to Medium (up to 2.5 MVA) | Massive (up to 1000 MVA) |

| Location | Poles, basements, streets | Fenced-off substations |

In the global market, the IEC 60076 distribution transformer standard is the bible of manufacturing. It covers everything from temperature rise limits to the ability to withstand short circuits. You can reference the official scope at the IEC Webstore.

However, simply “meeting IEC” is the baseline. Smart buyers look for:

(Check compliance and manufacturing standards here: Distribution Transformer Manufacturer)

Over-sizing wastes capital; under-sizing risks failure. Here is how to hit the sweet spot.

Don’t just sum up the connected wattage. You need the maximum demand.

If you are powering a data center or a factory full of Variable Frequency Drives (VFDs), standard transformers will overheat due to harmonics.

A “cheap” transformer is often expensive in the long run.

A transformer is only as good as its protection.

Q: What is the lifespan of a distribution transformer? A: With proper maintenance, specifically managing oil quality and preventing overloads, a unit can last 25 to 40 years.

Q: What maintenance is required? A:

Q: Can I run a distribution transformer at 110% load? A: Briefly, yes. IEC 60076-7 provides loading guides. You can overload during winter peaks without damage, provided the unit cools down afterward.

Q: How do I choose between Copper and Aluminum? A: Electrically, both perform equally if designed correctly. Copper is better for corrosive environments or where size constraints exist. Aluminum is better for budget-conscious utility projects.

A distribution transformer is a 30-year asset. The unit you buy today will likely still be humming decades from now. Choosing the right unit requires balancing the immediate capital cost (CAPEX) with the long-term operational cost (OPEX).

Whether you need a rugged pole mounted distribution transformer for a rural expansion or a high-efficiency pad mounted distribution transformer for a green building project, working with a reputable manufacturer is key.

Don’t leave your power network to chance.

👉 Ready to spec your project? Request a distribution transformer quotation today and ensure your infrastructure is built on quality.

Master your procurement strategy for 2025. This comprehensive guide provides expert checklists and technical standards for selecting MV/HV switchgear, vacuum breakers, and transformers in global markets.

Download 2025 Buyer’s Guide