¿Necesita las especificaciones completas?

Descargue nuestro Catálogo de productos 2025 para obtener planos detallados y parámetros técnicos de todos los componentes de los equipos de conmutación.

Obtener catálogo

Descargue nuestro Catálogo de productos 2025 para obtener planos detallados y parámetros técnicos de todos los componentes de los equipos de conmutación.

Obtener catálogo

Descargue nuestro Catálogo de productos 2025 para obtener planos detallados y parámetros técnicos de todos los componentes de los equipos de conmutación.

Obtener catálogo

Los disyuntores de vacío fallan de formas predecibles. La erosión de los contactos por la energía del arco, la desviación de la temporización por el desgaste del mecanismo, la degradación del aislamiento por la humedad... estos modos de deterioro se anuncian a través de indicadores medibles meses antes del fallo catastrófico.

A diferencia de los contactores, que conmutan cargas miles de veces al año, los VCB interrumpen los fallos ocasionalmente, pero deben funcionar a la perfección cuando se les llama. Un solo fallo en la eliminación de un cortocircuito puede provocar daños en los equipos, tiempos de inactividad prolongados e incidentes de seguridad. La diferencia entre un disyuntor que despeja una avería de 25 kA en 50 ms y uno que no interrumpe cuesta decenas o cientos de miles de dólares.

El mantenimiento detecta el deterioro a tiempo. Una inspección visual trimestral identifica las conexiones sueltas antes de que provoquen daños por arco eléctrico. Una prueba de sincronización anual revela una velocidad de apertura 15% más lenta, que aún no es un fallo, pero que tiende hacia el umbral de sustitución. El mantenimiento estructurado transforma los fallos aleatorios en sustituciones planificadas durante las paradas programadas.

Esta lista de comprobación proporciona las tareas de mantenimiento trimestrales y anuales específicas, los criterios de aceptación y las plantillas de registros de campo que los ingenieros necesitan para mantener disyuntor de vacío fiabilidad en instalaciones eléctricas, industriales y comerciales de 12-40,5 kV.

Tanto los disyuntores como los contactores utilizan interruptores de vacío, pero sus requisitos de mantenimiento difieren significativamente.

Comparación del ciclo de trabajo:

| Parámetro | Disyuntor de vacío | Contactor de vacío |

|---|---|---|

| Función principal | Interrupción por fallo | Conmutación de carga |

| Operaciones/año | 5-20 (eliminación de averías raras) | 5.000-50.000 (cambio frecuente de carga) |

| Corriente interrumpida | 10-40× nominal (cortocircuito) | 1-8× nominal (arranque/normal) |

| Energía del arco por operación | Muy alto (fallos de nivel kA) | Moderado (corrientes a nivel de carga) |

| Energía de arco acumulada | Moderado (pocas operaciones × alta energía) | Alta (muchas operaciones × energía moderada) |

| Consecuencia del fracaso | Catastrófico (destrucción de equipos, seguridad) | Moderado (interrupción del proceso) |

| Prioridad de mantenimiento | Integridad de la protección | Fiabilidad operativa |

El mantenimiento del VCB hace hincapié en disponibilidad-asegurar que el interruptor funcionará correctamente durante el raro evento de fallo. El mantenimiento de contactores hace hincapié en resistencia-seguimiento del desgaste acumulado por el cambio frecuente.

Los requisitos de mantenimiento también varían según disyuntor de vacío diseño, clase de tensión y entorno de aplicación. La aparamenta de interior puede requerir una limpieza más frecuente en entornos polvorientos, mientras que las instalaciones de exterior se enfrentan a problemas de intemperie y ciclos de temperatura.

Ambos requieren la medición de la resistencia de los contactos y comprobaciones de la integridad del vacío, pero los VCB añaden un enfoque crítico sobre la temporización/recorrido (la capacidad de interrupción depende de la velocidad de apertura) y la coordinación de la protección (los ajustes del relé deben coincidir con el rendimiento real del interruptor).

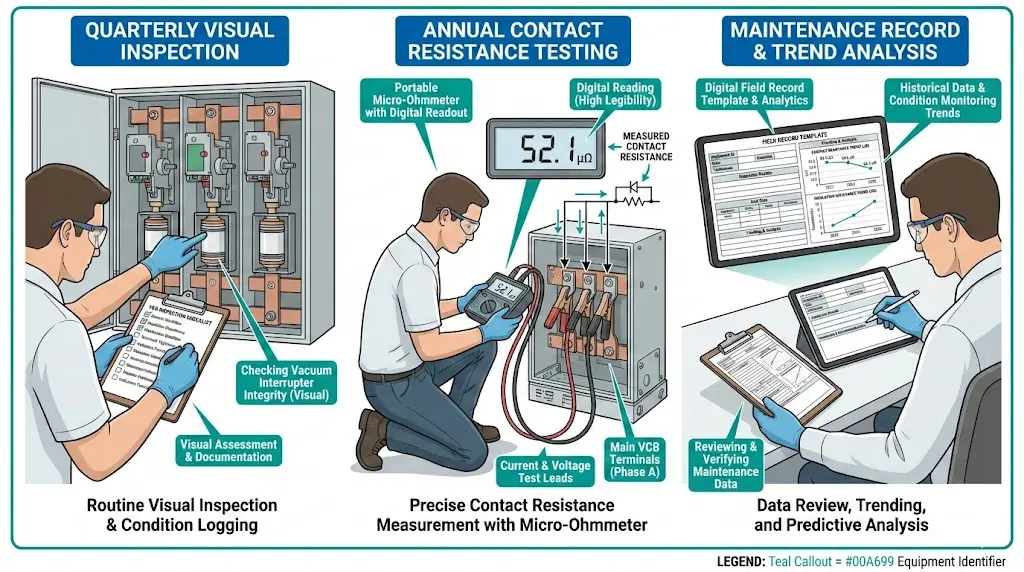

Combine activadores basados en el tiempo, el funcionamiento y las condiciones para una cobertura completa.

Alcance: Inspección visual, comprobaciones funcionales básicas

Duración: 30-60 minutos por disyuntor

Puede realizarse: Durante las rondas por las instalaciones, impacto mínimo en la producción

Tareas:

Alcance: Pruebas eléctricas y mecánicas detalladas

Duración2-4 horas por disyuntor

Requiere: Aislamiento de disyuntores, equipos de prueba especializados, personal formado

Tareas:

Alcance: Evaluación exhaustiva, a menudo coincide con cortes importantes.

Duración: Jornada completa por disyuntor (con acceso al panel)

Tareas:

Independientemente del tiempo, realice una inspección completa después:

Seguimiento de las operaciones a través de:

Realice una inspección inmediata no programada cuando:

Las revisiones trimestrales detectan los problemas antes de que requieran reparaciones urgentes.

Compruébalo:

Criterios de aceptación:

Medidas correctoras:

Procedimiento:

Aceptación:

Cuestiones que indican la necesidad de una inspección detallada:

Medición de la tensión:

Mida la tensión de control de CC en:

Aceptación85-110% de tensión nominal (por ejemplo, 110-138 V para un sistema de 125 V CC)

Baja tensión (<85%): Indica caída de tensión del cableado, batería débil, fallo del cargador

Alta tensión (>110%): Indica un mal funcionamiento del cargador, daño potencial de la bobina.

Comprobación de contactos auxiliares:

Conexiones críticas (control anual, control por muestreo trimestral):

Utilice una llave dinamométrica calibrada según las especificaciones del fabricante (normalmente):

Signos de conexiones sueltas:

Récord de tendencias:

Las temperaturas elevadas (>40°C sostenidos) o la humedad elevada (>85% HR) aceleran la degradación del aislamiento, por lo que puede ser necesario reducir la potencia o mejorar el control ambiental.

Las pruebas anuales verifican la integridad eléctrica y mecánica mediante parámetros medibles.

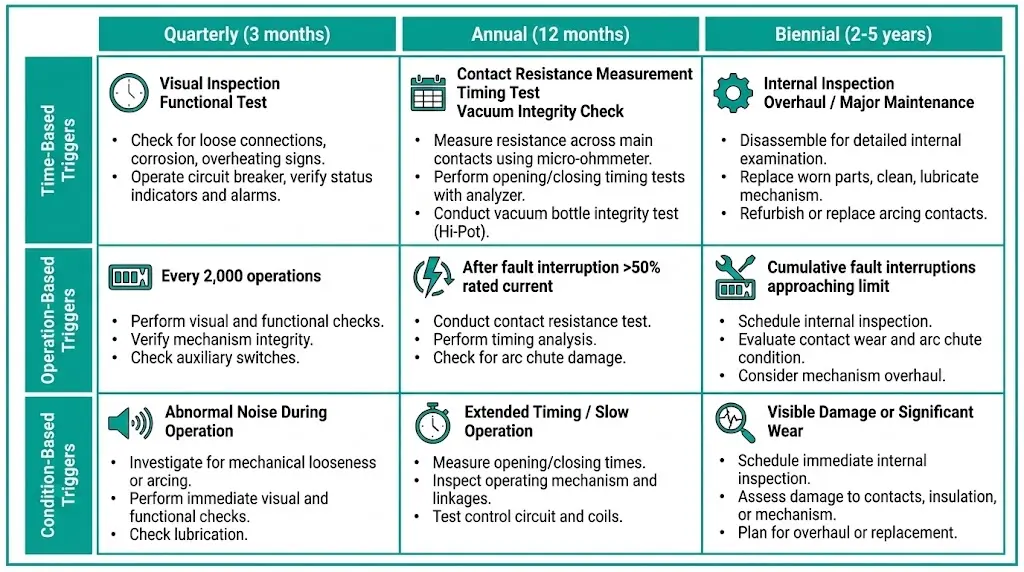

Propósito: Detecta la erosión de los contactos, la contaminación y la desalineación antes de que la resistencia provoque un sobrecalentamiento o una pérdida de capacidad de interrupción.

Equipo:

Procedimiento:

Valores típicos para VCB de 12-36 kV:

Evaluación:

| Resistencia | Tendencia | Acción |

|---|---|---|

| <80 μΩ | Estable | Aceptable, seguir controlando |

| 80-120 μΩ | Aumento gradual | Supervisar en el siguiente intervalo, planificar la sustitución |

| >120 μΩ | Acercándose al límite | Sustituir los contactos en la próxima interrupción |

| >150 μΩ | Superación del límite de servicio | Se requiere sustitución inmediata |

| Salto repentino (aumento >50%) | Anormal | Repetir la prueba para confirmar; si se confirma, investigar la desalineación o la contaminación. |

Variación entre polos:

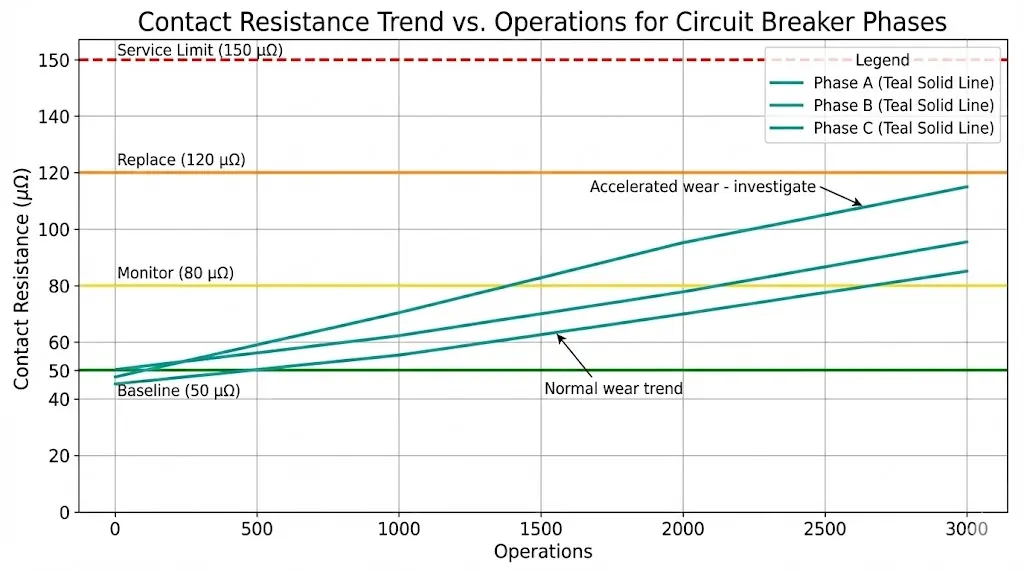

La capacidad de interrupción del VCB depende de la velocidad de apertura. Las pruebas de temporización verifican el rendimiento del mecanismo según las especificaciones del fabricante.

Equipamiento necesario:

Medidas:

Horario de apertura: Tiempo desde la activación de la bobina de disparo hasta la separación de los contactos

Hora de cierre: Tiempo desde la activación de la bobina de cierre hasta el contacto

Contacto viajes: Distancia total que recorren los contactos de completamente abiertos a completamente cerrados

Velocidad: Velocidad media de separación de los contactos durante la apertura

Procedimiento:

Criterios de aceptación:

Condiciones fuera de especificación:

| Síntoma | Causa probable | Remedio |

|---|---|---|

| Tiempo de apertura lento (>10% sobre especificación) | Lubricante seco, fatiga del muelle, fricción | Lubricar, ajustar, sustituir muelles |

| Tiempo de apertura rápido (>10% bajo especificación) | Muelles sobretensados, amortiguación reducida | Ajustar la tensión del muelle, comprobar el amortiguador |

| Temporización incoherente (varía >15% entre operaciones) | Encuadernación, juego mecánico, desgaste del pestillo | Inspeccionar el mecanismo, sustituir las piezas desgastadas |

| Recorrido bajo (<90%) | Desgaste del mecanismo, hinchazón del interruptor de vacío (pérdida de vacío) | Ajustar el mecanismo; si se pierde el vacío, sustituir VI |

| Desplazamiento excesivo (>110%) | Pérdida del ajuste del tope, riesgo de daños por sobrecarrera | Ajustar los topes mecánicos |

Verifica la integridad del aislamiento entre las partes activas y tierra, evitando corrientes de fuga y descargas eléctricas.

Equipo: Comprobador de resistencia de aislamiento (Megger), tensión de prueba de 2,5 kV o 5 kV

Puntos de prueba:

Baja resistencia de aislamiento (<100 MΩ en el circuito principal):

Tendencias: Realice un seguimiento de la resistencia del aislamiento a lo largo del tiempo. Una disminución gradual indica que se está desarrollando un problema, aunque siga estando por encima del mínimo.

La rigidez dieléctrica de los interruptores de vacío depende del mantenimiento de un alto vacío (<10-⁴ Pa). La pérdida de vacío puede no impedir la conmutación de la carga, pero falla catastróficamente durante la interrupción del fallo.

Método 1: Prueba de resistencia a alta tensión (más definitivo)

Equipo: Equipo de prueba de alta tensión CA, 10-50 kV ajustable

Procedimiento:

Aceptación:

Método 2: Resistencia de aislamiento a tensión reducida (campo-expediente)

Procedimiento:

Menos definitiva que la prueba de alto voltaje, pero adecuada para el cribado rutinario.

Método 3: Medición de la corriente de apantallamiento (avanzado, requiere equipo especializado)

Algunos fabricantes proporcionan puertos de medición de corriente de blindaje para la evaluación no invasiva del vacío.

Comprobación de la lubricación:

Acción:

Inspección de desgaste:

Comprobación de alineación:

Relés auxiliares:

Ajustes del relé de protección:

Anunciación:

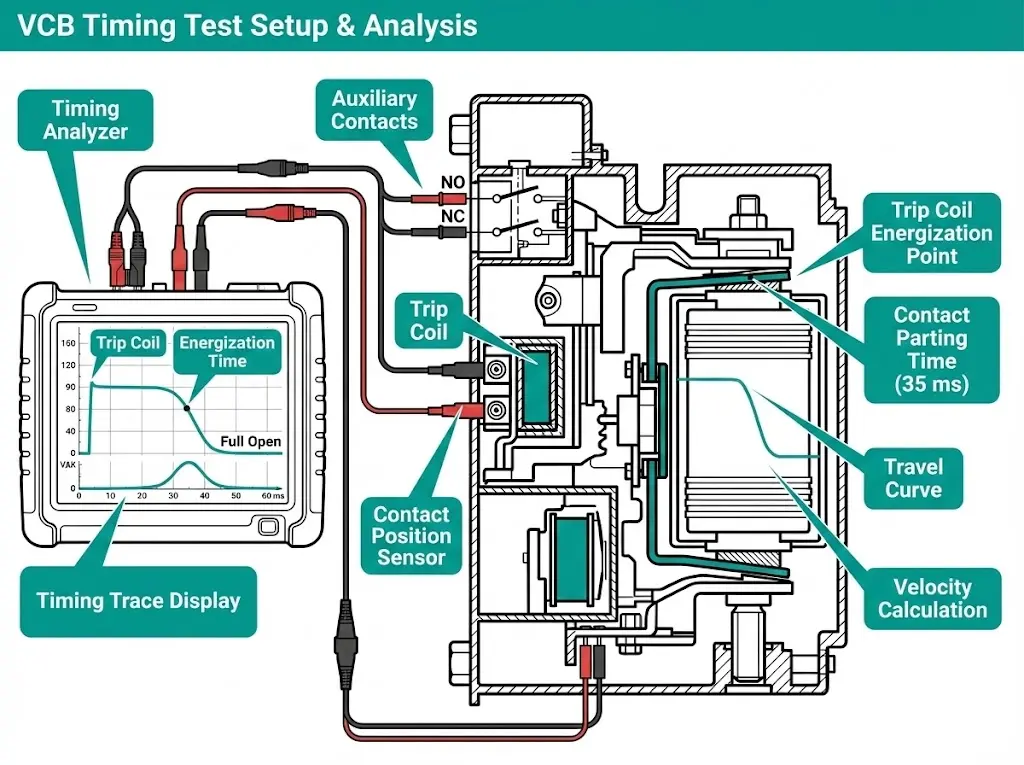

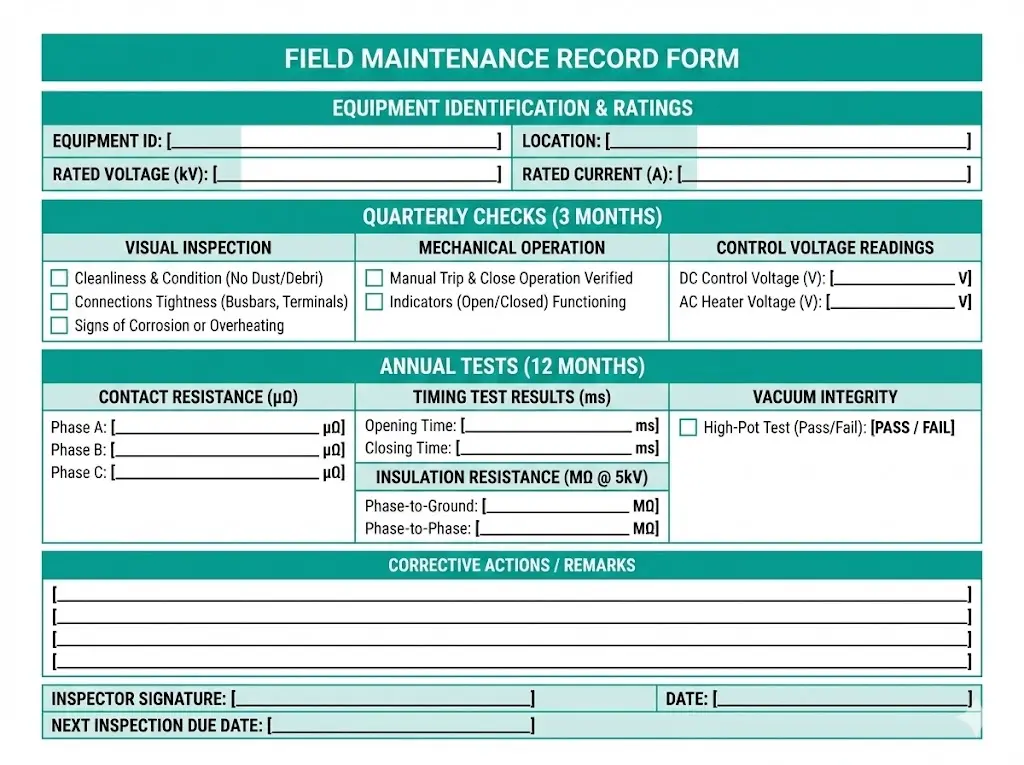

Una documentación coherente permite analizar las tendencias. Utilice esta plantilla o adáptela a su sistema GMAO.

REGISTRO DE MANTENIMIENTO DEL DISYUNTOR DE VACÍO

Equipo ID: ________________ Ubicación: ________________

Fabricante: ________________ Número de serie: ________________

Tensión nominal: _______ kV Corriente nominal: _______ A

Cortocircuito nominal: _______ kA Año de instalación: _______

TIPO DE MANTENIMIENTO: [ ] Trimestral [ ] Anual [ ] Post-fallo

Fecha: _______________ Operaciones desde la última inspección: _______

Temperatura ambiente: _____ °C Humedad: _____ %

═══════════════════════════════════════════════════════════

CONTROLES TRIMESTRALES (si procede):

Inspección visual:

[ ] Exterior limpio, sin marcas

[ ] Sin daños físicos ni grietas

[ ] Sin humedad/corrosión

[ ] Ventilación adecuada

Funcionamiento mecánico:

[ ] Cierra suavemente

[ ] Se dispara rápidamente

[ ] Se cierra correctamente

[ ] El motor de carga se detiene correctamente

Tensión de control (medida):

Bobina de disparo: _______ V (Especificación: 85-110% de _____ V)

Bobina de cierre: _______ V

Auxiliar: _______ V

Comprobación de conexiones:

[ ] No se observan conexiones sueltas

[ ] No hay decoloración alrededor de los terminales

═══════════════════════════════════════════════════════════

PRUEBAS ANUALES (si procede):

RESISTENCIA AL CONTACTO (μΩ):

Fase A: _______ (Línea de base: _____) Estado: [ ] OK [ ] Vigilar [ ] Sustituir

Fase B: _______ (Línea de base: _____) Estado: [ ] OK [ ] Supervisar [ ] Sustituir

Fase C: _______ (línea de base: _____) Estado: [ ] OK [ ] Supervisar [ ] Sustituir

PRUEBA DE TIEMPO

Tiempo de apertura: _______ ms (Espec: _____ ± _____ ms) [ ] Pasa [ ] Falla

Tiempo de cierre: _______ ms (Especificación: _____ ± _____ ms) [ ] Pasa [ ] No pasa

Recorrido de contacto: _______ mm (Especificación: _____ ± _____ mm) [ ] Pasa [ ] No pasa

Velocidad media: _______ m/s (Especificación mínima: _____ m/s) [ ] Pasa [ ] No pasa

RESISTENCIA DE AISLAMIENTO (MΩ):

Fase A a tierra: _______ (Mín: 1000 MΩ) [ ] Pasa [ ] No pasa

Fase B a tierra: _______ (Mín: 1000 MΩ) [ ] Pasa [ ] Falla

Fase C a tierra: _______ (Mín: 1000 MΩ) [ ] Pasa [ ] Falla

Circuito de control: _______ (Mín: 10 MΩ) [ ] Pasa [ ] Falla

INTEGRIDAD DEL VACÍO:

Método de prueba utilizado: [ ] Resistencia HV [ ] Prueba Megger [ ] Corriente de apantallamiento

Resultado: [ ] Pasa (vacío intacto) [ ] Falla (vacío perdido)

En caso de fallo: Es necesario sustituir el interruptor: [ ] Sí

INSPECCIÓN DEL MECANISMO:

[ ] Estado de lubricación aceptable

[ ] No se observa desgaste excesivo

[ ] Alineación dentro de tolerancia

[ ] Muelles en buen estado

═══════════════════════════════════════════════════════════

MEDIDAS CORRECTORAS ADOPTADAS:

____________________________________________________________

____________________________________________________________

PIEZAS SUSTITUIDAS:

____________________________________________________________

PRÓXIMA INSPECCIÓN PREVISTA:

Fecha: _______________ O Operaciones: _______

ESTADO DEL MARTILLO:

[ ] Retornado al servicio (todas las pruebas superadas)

[Fuera de servicio (requiere reparaciones)

[ ] Sustitución de contactos programada para: _______________

Inspector: _____________________ Signature: __________

Revisado por: ___________________ Fecha: ____________

Las mediciones individuales son instantáneas. Las tendencias revelan patrones de deterioro.

Parámetros clave de la tendencia:

Acciones de mantenimiento predictivo:

Tendencias de la flota:

Si mantiene varios VCB idénticos, compárelos:

| Síntoma | Prueba diagnóstica | Causa probable | Remedio |

|---|---|---|---|

| No tropieza | Comprobar la tensión de la bobina de disparo | Baja tensión, circuito abierto | Corregir la alimentación de tensión, reparar el cableado |

| Comprobar el varillaje mecánico | Encuadernación, atasco mecánico | Mecanismo libre, lubricar | |

| Prueba del circuito antibombeo | Falso bloqueo | Reiniciar relé, verificar circuito | |

| No se cierra | Comprobar la tensión de la bobina de cierre | Baja tensión, fallo de bobina | Corregir la alimentación, sustituir la bobina |

| Carga del mecanismo de control | Muelle descargado, presión hidráulica baja | Mecanismo de carga | |

| Verificar los enclavamientos | Enclavamiento que impide el cierre | Comprobar estado de enclavamiento, borrar fallo | |

| Tiempo de apertura lento | Prueba de sincronización | Lubricación seca, fatiga del muelle | Relubricar, sustituir muelles |

| Medir la fuerza del muelle | Resorte débil | Sustituir el conjunto de muelles | |

| Contacto rebote | Análisis de la traza temporal | Velocidad de cierre excesiva, pérdida de amortiguación | Ajustar la velocidad de cierre, sustituir la compuerta |

| Alta resistencia de contacto | Tendencia de la resistencia | Erosión por contacto, desalineación | Limpiar contactos (si accesibles), sustituir si >límite |

| Baja resistencia de aislamiento | Medición con humedad controlada | Humedad | Secar el panel, mejorar la estanqueidad |

| Inspección visual | Contaminación, seguimiento | Limpie los aisladores, sustitúyalos si presentan huellas | |

| Prueba de vacío fallida | Prueba de integridad al vacío | Degradación del interruptor de vacío | Sustituir el interruptor de vacío |

El mantenimiento del VCB implica energía almacenada, alta tensión y riesgos mecánicos.

Antes de empezar a trabajar:

Durante las pruebas:

Después del mantenimiento:

Para procedimientos detallados sobre tipos específicos de VCB, consulte las guías de mantenimiento del fabricante.

Referencia externa: IEC 62271-106 - Norma IEC 62271-106 para contactores de CA

P1: ¿Con qué frecuencia debo realizar pruebas de resistencia de contacto en un VCB?

R: Anualmente para disyuntores de distribución estándar, semestralmente para disyuntores de generador o esquemas de transferencia con operaciones frecuentes (>500 operaciones/año). Comprobar siempre después de cualquier interrupción de falta >50% de corriente nominal de cortocircuito, ya que la energía del arco de falta acelera la erosión de los contactos.

P2: ¿Cuál es la diferencia entre el mantenimiento de VCB y el mantenimiento de contactores?

R: Los VCB hacen hincapié en la preparación de la protección (precisión de temporización, capacidad de interrupción), mientras que los contactores hacen hincapié en la resistencia operativa (seguimiento del desgaste acumulado). Los VCB requieren un análisis de temporización/recorrido más detallado porque la interrupción del fallo depende de la velocidad de separación precisa de los contactos; los contactores se centran más en la tendencia de la resistencia de los contactos debido a la exposición frecuente a los arcos.

P3: ¿Puedo realizar pruebas de integridad del vacío sin equipos de alta tensión?

R: Sí: utilice un Megger de 1.000-2.500 V a través de contactos abiertos como prueba de detección rápida en campo. Un buen vacío muestra una resistencia >100 MΩ. Este método es menos definitivo que la prueba de resistencia a alta tensión, pero adecuado para comprobaciones anuales rutinarias. Realice la prueba de alta tensión cada 3-5 años o si los resultados del Megger son marginales.

P4: ¿Qué hace que la temporización se desvíe de las especificaciones con el paso del tiempo?

R: Causas principales: (1) envejecimiento de la lubricación-la grasa se seca o licua, aumentando la fricción; (2) fatiga de los muelles-los muelles pierden tensión a lo largo de miles de operaciones; (3) desgaste mecánico-los orificios del pivote se alargan, los pasadores del enganche se desgastan, creando holgura; (4) desgaste del pestillo-reduce el tiempo de enganche. Un desplazamiento gradual es normal; los cambios repentinos indican un fallo específico del componente.

P5: ¿Cómo sé cuándo debo sustituir los contactos frente a todo el interruptor en vacío?

R: Si la resistencia de los contactos excede el límite de servicio (típicamente 150 μΩ) O falla la integridad del vacío, se debe reemplazar todo el interruptor en vacío-los contactos y la envoltura de vacío son una unidad sellada que no se puede reparar en campo. Coste: $300-$1.500 por interruptor dependiendo de la tensión/corriente nominal. Tiempo de sustitución: 2-6 horas por VCB.

P6: ¿Debe realizar el mantenimiento trimestral y anual el mismo personal?

R: Las comprobaciones trimestrales pueden ser realizadas por electricistas de las instalaciones familiarizados con el equipo. Las pruebas anuales requieren equipos de prueba especializados (microóhmetro, analizador de temporización, equipo de prueba de alta tensión) y formación para la interpretación de los resultados.

P7: ¿Cómo afectan las interrupciones por avería a los intervalos de mantenimiento?

R: Cada interrupción de fallo provoca una erosión significativa de los contactos y tensión mecánica. Realice pruebas de resistencia y temporización de los contactos después de CUALQUIER interrupción de fallo >50% de corriente nominal de cortocircuito. Múltiples operaciones de fallo pueden consumir años de vida operativa normal en segundos; ajuste la planificación de sustitución en consecuencia basándose en el historial de fallos, no sólo en el número de operaciones.