Need Full Specifications?

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

Standard vacuum circuit breakers carry mechanical endurance ratings of 10,000 operations—adequate for facilities switching once or twice daily. Mining hoists, electric arc furnaces, and heavy motor drives operate differently: 50 to 200+ cycles every 24 hours. At 100 operations per day, a standard VCB exhausts its rated life in under three years.

This selection guide identifies the engineering specifications, mechanism types, and application-specific factors that separate high-endurance VCBs from standard units. The goal: match breaker capability to actual duty cycles, avoiding premature failures and unplanned outages.

A typical 12kV VCB carries mechanical endurance of 10,000 operations (Class M2 per IEC 62271-100) and electrical endurance of 2,000 operations at rated short-circuit current (Class E1). For substations switching once daily, these numbers translate to decades of service. Frequent-switching applications operate in a different reality.

The Mathematics of Premature Failure

Consider a mine hoist VCB cycling 80 times per day:

An electric arc furnace running 20 heats daily with 4 switching operations per heat reaches identical exhaustion timelines. These calculations assume ideal conditions without accounting for accelerated wear from high fault currents.

Contact Erosion: The Non-Linear Reality

Contact wear does not progress linearly. Laboratory testing and field data reveal a three-phase pattern:

The final 2,000 operations of a 10,000-operation interrupter may consume contact material equivalent to 4,000–6,000 steady-state operations. Simple operation counts underestimate wear as contacts approach end-of-service.

Vacuum Integrity Under Cyclic Stress

Each cycle flexes the stainless steel bellows sealing the vacuum interrupter. Standard bellows designs carry cycle ratings of 10,000–15,000 full-stroke cycles. High-cycle applications stress bellows beyond these assumptions, initiating micro-cracks at weld joints. Unlike contact erosion, vacuum degradation offers limited advance warning—an interrupter may test satisfactory at 9,500 operations and fail catastrophically at 10,200.

For frequent-switching duty, proactive replacement beats condition monitoring.

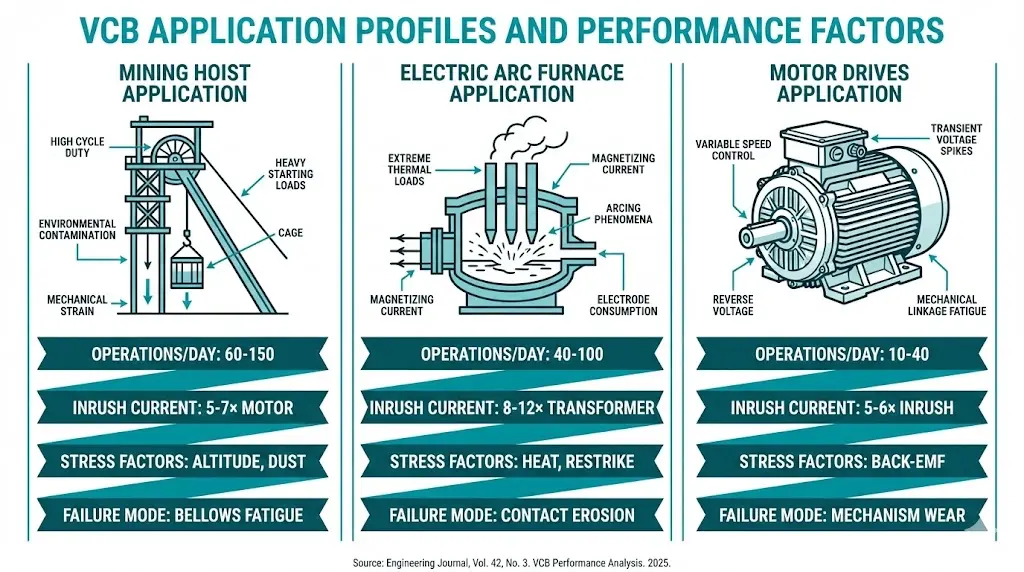

Understanding specific duty cycle characteristics guides specification decisions. Each application presents unique electrical and environmental stresses.

Mining Hoists and Winders

Production hoists execute 60–150 operations daily during active extraction. Each start subjects the VCB to motor inrush currents of 5–7× rated load. Regenerative braking creates voltage spikes requiring careful transient recovery voltage coordination.

Environmental factors compound the challenge. Many mining operations sit above 2,000m elevation—Andean copper mines, Tibetan plateau extraction sites. Dielectric strength decreases approximately 1% per 100m above 1,000m. Dust ingress and temperature extremes (-30°C to +45°C) stress sealing systems.

Field experience across Chilean copper operations shows that even VCBs specified at 30,000+ mechanical endurance require planned interrupter replacement at 18–24 month intervals for critical hoist circuits.

Electric Arc Furnace Switching

EAF operations present the most demanding switching duty in industrial applications. A typical melt shop runs 15–25 heats daily, with 2–4 switching operations per heat—40 to 100 VCB operations every 24 hours.

The electrical stress is severe. Transformer magnetizing inrush reaches 8–12× rated current with asymmetric DC offset decaying over 0.5–2 seconds. De-energizing unloaded transformers creates restrike risk, potentially damaging winding insulation through steep-front voltage surges.

Ambient conditions near furnaces routinely exceed 45°C. Metallic dust contaminates surrounding equipment.

Frequent-Start Motor Drives

Crushers, ball mills, and conveyor drives typically see 10–40 starts daily—moderate compared to hoists or EAF, but still exceeding standard VCB design assumptions. Motor switching differs from transformer switching: higher power factor, lower inrush asymmetry, but back-EMF risk during fast re-closing when motors remain spinning.

For applications under 7.2kV, below 400A, and fewer than 1,000 operations daily, vacuum contactors often prove more economical than VCBs.

[Expert Insight: Mining Application Realities]

- Chilean and Peruvian copper mines above 3,000m elevation require both altitude-rated insulation AND sealed enclosures

- Hoist circuit VCBs experience 3× higher contact erosion rates than nameplate calculations suggest due to regenerative braking transients

- Planned interrupter rotation (two units alternating service) extends effective maintenance windows by 40%

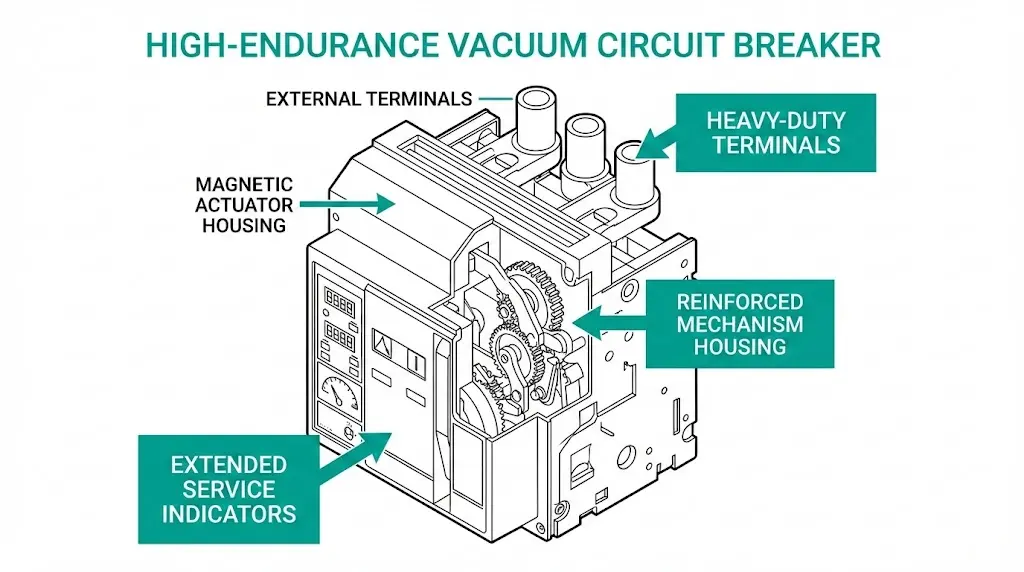

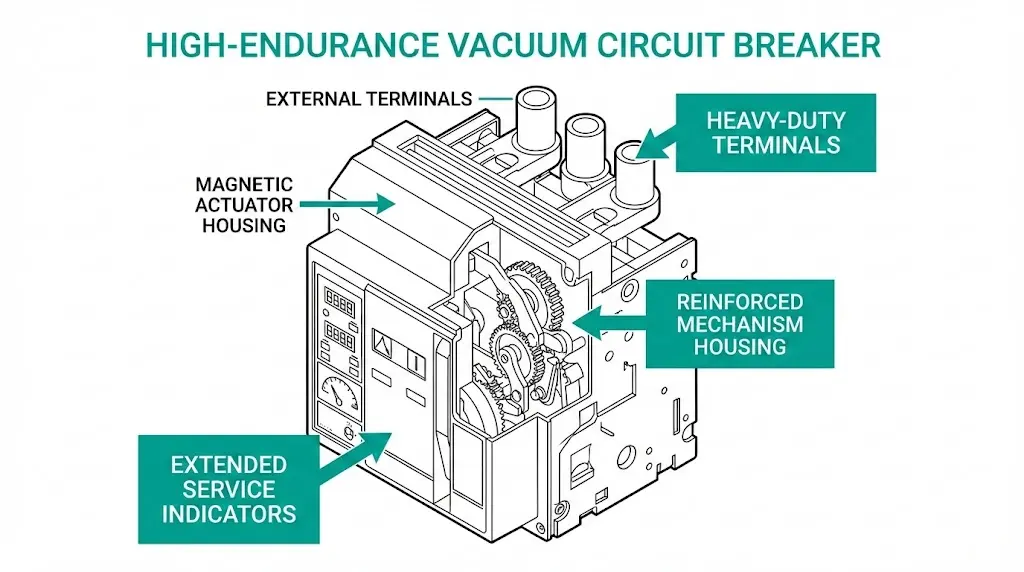

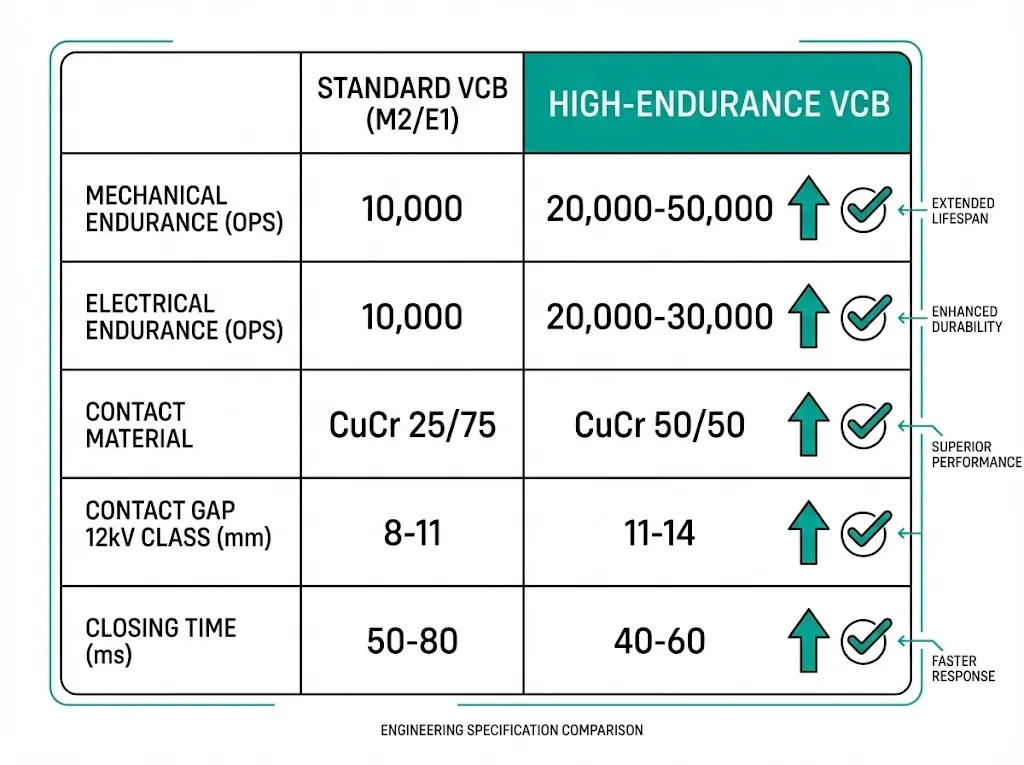

Specification comparison reveals the engineering differences between standard and high-endurance designs. These parameters directly determine service life under frequent-switching conditions.

| Parameter | Standard VCB (M2/E1) | High-Endurance VCB | Selection Notes |

|---|---|---|---|

| Mechanical endurance | 10,000 operations | 20,000–50,000 operations | Match to 5-year operation projection |

| Electrical endurance (rated current) | 10,000 operations | 20,000–30,000 operations | Contact material dependent |

| Electrical endurance (short-circuit) | 2,000 operations (E1) | 5,000+ operations (E2) | Rarely limiting in practice |

| Contact material | CuCr 25/75 | CuCr 50/50 or CuCr-Te | Higher Cr = better erosion resistance |

| Contact gap (12kV class) | 8–11mm | 11–14mm | Larger gap accommodates erosion |

| Closing time | 50–80ms | 40–60ms | Faster = reduced arc energy |

Contact Material Selection

CuCr ratio determines erosion rate and chopping current behavior. Standard CuCr 25/75 (25% chromium) provides adequate performance for typical distribution duty. CuCr 50/50 delivers 30–40% better erosion resistance—critical when projecting 30,000+ operations.

Specialty alloys containing tellurium or bismuth (CuCr-Te, CuCr-Bi) further reduce erosion for extreme duty cycles. Request manufacturer erosion test data per IEC 62271-100 Annex E for your specific switching duty.

Mechanism Life Alignment

The operating mechanism must match or exceed interrupter endurance. Spring mechanism wear points—cam followers, latches, charging motors—accumulate damage with each cycle. Lubrication intervals increase with operation count. A 30,000-operation interrupter paired with a 20,000-operation mechanism creates a maintenance mismatch.

Auxiliary Contact Ratings

Often overlooked during specification. Auxiliary contacts for protection relay signaling must match main contact mechanical endurance. Standard auxiliary blocks may fail before the primary interrupter reaches service limits.

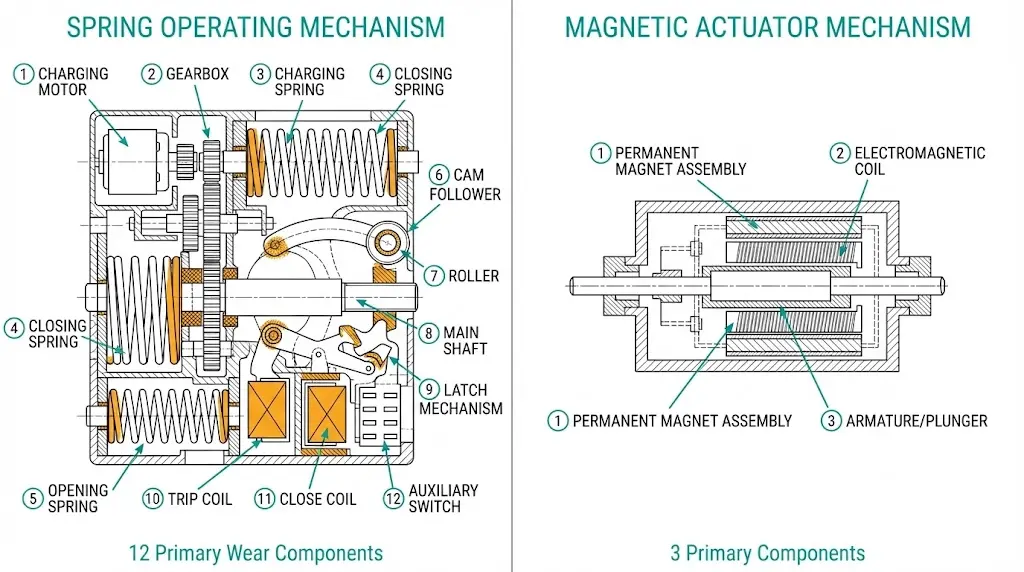

The operating mechanism determines maintenance burden and ultimate operational life. Two technologies dominate high-endurance applications.

Spring-Operated Mechanisms

Proven technology with broad market availability. Energy storage via charged spring enables operation during control power interruption. However, mechanical wear points limit ultimate endurance:

Lubrication intervals typically fall at 2,000–5,000 operations. Practical service limit: 20,000–30,000 operations before major overhaul. Lower initial cost makes spring mechanisms appropriate for moderate-duty applications below 30,000 lifetime operations.

Magnetic Actuator Mechanisms

Permanent magnets hold contact position without mechanical latching. Electromagnetic coils drive opening and closing motions. This design eliminates most mechanical wear surfaces.

Key advantages for frequent-switching duty:

The cost premium runs 15–25% above equivalent spring mechanisms. For applications projecting 50,000+ lifetime operations, magnetic actuators deliver lower total cost of ownership despite higher acquisition price.

[Expert Insight: Mechanism Selection Economics]

- Break-even point typically occurs at 35,000–40,000 projected operations

- Magnetic actuator VCBs show 60% lower unplanned maintenance costs over 10-year service life

- Spring mechanism overhaul labor (8–12 hours) often exceeds magnetic actuator total maintenance time (2–3 hours) across equivalent operational periods

- Hybrid designs (spring closing, magnetic holding) require evaluation of total moving part count—not always superior to pure magnetic designs

The vacuum interrupter itself determines electrical endurance. Design features distinguish high-endurance units from standard production.

Contact Geometry

Three primary designs serve different duty requirements:

AMF designs reduce localized erosion by 30–40% compared to radial field configurations. For applications above 25kA fault duty with frequent switching, AMF contacts justify their cost premium.

Contact Gap Sizing

Standard 12kV interrupters use 8–11mm contact gaps. High-endurance designs extend this to 11–14mm, providing erosion allowance while maintaining dielectric withstand. As contacts erode, the gap increases—larger initial gaps ensure adequate dielectric margin throughout service life.

Arc Energy Budget

Each switching operation deposits arc energy into contact surfaces. The integral ∫i²dt determines material transfer per operation. Practical erosion rates:

Interrupter design must accommodate this material reserve in contact thickness and vapor shield capacity.

Bellows Construction

Stainless steel edge-welded bellows seal the vacuum chamber while permitting contact motion. High-cycle designs use optimized convolution geometry rated for 1.5–2× the mechanical endurance target. Bellows failure causes immediate vacuum loss with no partial degradation warning.

Site conditions frequently require specification adjustments beyond standard ratings.

Altitude Derating

Standard vacuum circuit breaker ratings apply to 1,000m elevation. Above this threshold, reduced air density decreases external dielectric strength:

Internal vacuum dielectric remains unaffected by altitude—only external creepage and clearance require compensation.

Temperature Considerations

Standard ambient range spans -25°C to +40°C. EAF environments regularly exceed 45°C, requiring either current derating (typically 1% per °C above 40°C) or enhanced cooling provisions.

Cold environments present different challenges. Mechanism lubricants must maintain viscosity at operating temperature. Anti-condensation heaters prevent moisture accumulation during temperature cycling.

Contamination Protection

Mining environments demand minimum IP4X enclosure ratings. Conductive dust from ore processing can bridge external insulation surfaces. Pressurized switchgear housings provide additional protection in severe contamination environments.

Proactive maintenance extends service life and prevents unplanned failures. High-cycle applications require compressed inspection intervals.

Condition Monitoring Requirements

Inspection Intervals by Operation Count

| Interval | Required Actions |

|---|---|

| 2,500 operations | Visual inspection, auxiliary contact verification |

| 5,000 operations | Lubrication check (spring mechanisms), timing test |

| 10,000 operations | Contact resistance measurement, mechanism adjustment, detailed inspection |

| Rated mechanical life | Full overhaul or interrupter replacement |

Spare Parts Strategy

Stock complete interrupter assemblies for applications exceeding 50 daily operations. Waiting for manufacturer delivery during an unplanned outage costs far more than inventory carrying costs. Also stock mechanism rebuild kits and closing/opening coils—high-cycle duty accelerates coil insulation aging.

Match VCB specification to projected duty cycle using this framework:

| Daily Operations | Recommended Specification | Inspection Cycle | Rebuild Interval |

|---|---|---|---|

| <10 ops/day | Standard M2/E1 VCB | Annual | 10–15 years |

| 10–50 ops/day | Extended-life (20,000+ mechanical) | Semi-annual | 5–8 years |

| 50–150 ops/day | High-endurance (30,000+), magnetic actuator preferred | Quarterly | 3–5 years |

| >150 ops/day | Premium high-endurance OR dual-unit rotation | Monthly | 2–3 years |

Cost-Benefit Analysis

High-endurance VCB premium typically runs 20–40% above standard units. Evaluate against:

For critical circuits in mining or EAF applications, the premium pays back within the first avoided unplanned outage.

Dual-Breaker Rotation Strategy

Extreme duty applications (>200 operations daily) benefit from installing two VCBs in rotation. One unit operates while the second undergoes maintenance or stands in reserve. This approach doubles effective service intervals and eliminates single-point failure risk for critical loads.

Review vacuum circuit breaker ratings documentation to verify manufacturer claims align with your duty cycle projections.

XBRELE engineers vacuum circuit breakers for demanding industrial duty cycles. Our VS1 indoor series and ZN85 embedded pole designs are available in high-endurance configurations:

Our technical team reviews your actual duty cycle data—daily operations, fault current exposure, environmental conditions—to recommend specifications matching real-world requirements rather than conservative nameplate assumptions.

[Request High-Endurance VCB Technical Consultation]

How many daily operations qualify as “frequent switching” for VCB selection?

Applications exceeding 30 switching operations per day generally benefit from high-endurance VCB specifications. Below this threshold, standard Class M2 breakers typically provide adequate service life with normal maintenance intervals.

What distinguishes high-endurance vacuum interrupters from standard designs?

High-endurance interrupters feature increased contact mass (larger erosion budget), optimized CuCr alloy composition with higher chromium content, extended contact gaps accommodating wear, and bellows rated for 1.5–2× the mechanical endurance target.

When should I specify a magnetic actuator over a spring mechanism?

Magnetic actuators become cost-effective when projected lifetime operations exceed 35,000–40,000 cycles. Below this threshold, spring mechanisms offer lower acquisition cost without significant maintenance penalty.

How does altitude affect VCB selection for mining applications?

External dielectric strength decreases approximately 1% per 100m above 1,000m elevation. At 3,000m, either derate voltage ratings by 20% or specify enhanced external insulation. Internal vacuum dielectric remains unaffected by altitude.

Can contact resistance measurement predict remaining interrupter life?

Monthly contact resistance trending using a 100A or higher micro-ohmmeter typically provides 3–6 months advance warning of approaching end-of-life. Rising resistance indicates contact erosion progression and surface degradation.

What contact material provides best performance for EAF transformer switching?

CuCr 50/50 or specialty alloys (CuCr-Te) deliver 30–40% better arc erosion resistance than standard CuCr 25/75 formulations. The higher chromium content proves critical for applications combining high current magnitude with frequent switching.

Should I stock spare interrupter assemblies for high-cycle applications?

For applications exceeding 50 daily operations, maintaining one spare interrupter assembly on-site eliminates lead time during planned or unplanned replacements. The inventory cost typically represents less than one hour of production downtime value.