Need Full Specifications?

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

When vacuum circuit breaker quotations arrive, test documentation often determines which supplier earns the contract. Some provide comprehensive type test certificates from accredited laboratories. Others send factory routine test sheets. Both reference IEC 62271-100—but they prove fundamentally different things.

Type tests validate a design. Routine tests validate each manufactured unit. Confusing these categories leads to specification gaps, commissioning failures, or warranty disputes that could have been avoided with precise RFQ language.

This guide breaks down what IEC 62271-100 requires for each test category, which reports you should demand, and the specific questions that separate thorough suppliers from those cutting corners.

IEC 62271-100 is the International Electrotechnical Commission’s definitive standard for AC circuit breakers rated above 1 kV. For medium-voltage vacuum circuit breakers—typically 3.6 kV to 40.5 kV—this standard defines rated characteristics, construction requirements, and the tests proving those ratings hold true.

The standard creates two distinct verification layers:

Type tests validate the design itself. When a manufacturer claims their vacuum circuit breaker interrupts 25 kA at 12 kV, type tests prove that claim. Performed at accredited high-power laboratories, these tests stress representative samples to their limits—sometimes destroying them. Once a design passes, results remain valid unless significant modifications occur.

Routine tests validate each manufactured unit. Every breaker leaving the factory undergoes these checks. They confirm proper assembly, contact engagement, insulation integrity, and mechanical function. Routine tests catch manufacturing defects—not design flaws.

This separation matters for procurement. A supplier providing only routine test certificates has proven their factory built each unit correctly. Without type test documentation, you have no evidence the underlying design meets its rated performance. Conversely, impressive type test reports mean nothing if routine testing is superficial.

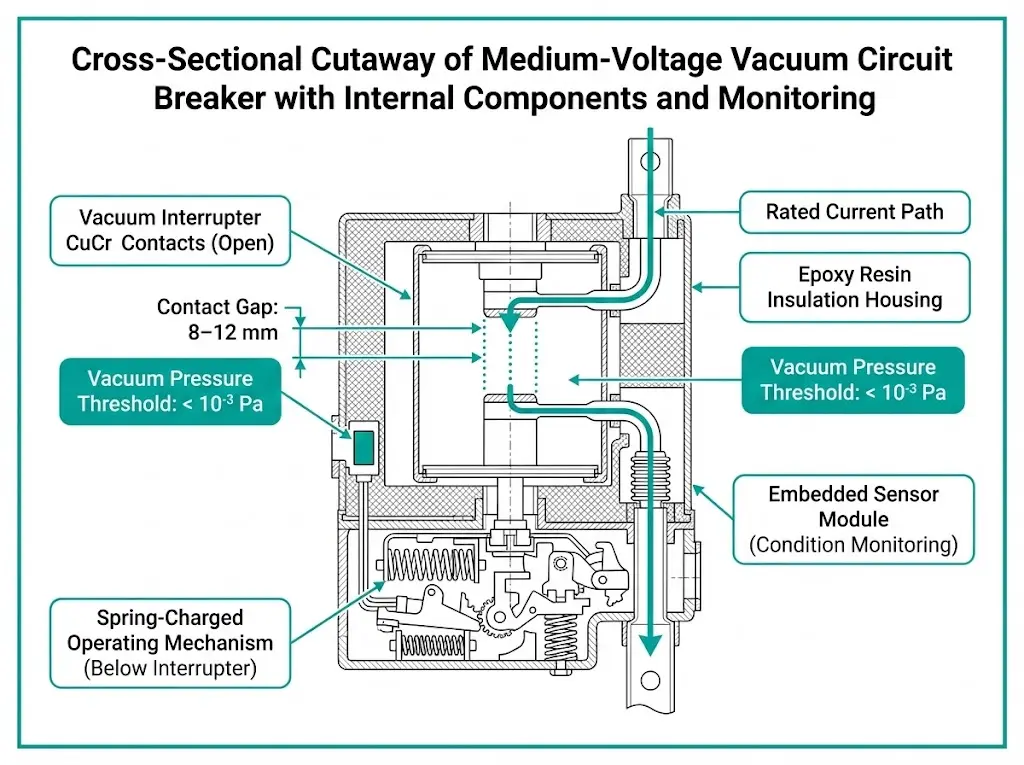

Understanding why vacuum circuit breakers require dual-layer verification connects directly to arc extinction physics. The working principle explained at https://xbrele.com/what-is-vacuum-circuit-breaker-working-principle/ shows why short-circuit interruption capability cannot be verified through simple factory checks.

Type tests demonstrate that a circuit breaker design meets all rated characteristics under worst-case conditions. These examinations occur on representative samples—not every unit. A complete type test program spans months and requires specialized facilities. Investment runs into hundreds of thousands of dollars per breaker family.

| Test Category | What It Proves | Typical Facility |

|---|---|---|

| Dielectric tests | Insulation withstands rated lightning impulse (BIL) and power-frequency voltage | High-voltage laboratory |

| Temperature-rise tests | Contacts and conductors stay within thermal limits at rated continuous current | Climate-controlled test bay |

| Short-circuit making and breaking | Breaker interrupts and closes on rated fault current across test duties (T10, T30, T60, T100) | High-power laboratory |

| Mechanical endurance | Mechanism survives rated operation count (typically 10,000 for VCB) | Manufacturer or third-party lab |

| Short-time withstand | Main circuit carries rated short-time current (1s or 3s) without damage | High-power laboratory |

| Critical current tests | Verifies performance at low fault currents where arc instability increases | High-power laboratory |

A legitimate type test report contains:

If a supplier provides only summary sheets without oscillograms or laboratory accreditation details, request the complete package.

[Expert Insight: Type Test Report Evaluation]

- Oscillograms are non-negotiable—summary tables without waveforms can be fabricated

- Check that the tested sample’s vacuum interrupter matches current production; VI substitution invalidates prior testing

- Reports older than 10 years warrant revalidation evidence, especially if component suppliers changed

- Test duties T100 (100% rated breaking current) provide the most demanding validation

Routine tests confirm each manufactured circuit breaker left production without defects. These occur at the factory on 100% of shipped units. They verify assembly quality and basic functionality without stressing the breaker to design limits.

| Routine Test | Acceptance Criterion |

|---|---|

| Power-frequency voltage withstand (dry) | No flashover or puncture at rated voltage × specified multiplier (typically 42 kV for 12 kV equipment) |

| Main circuit resistance measurement | Below design limit—typically 20–80 μΩ depending on rating |

| Mechanical operation test | Correct O-CO sequence timing; no binding or misfires |

| Auxiliary circuit wiring check | Continuity and insulation of control wiring |

| Visual inspection | No visible damage, proper labeling, nameplate accuracy |

For each delivered unit:

| Aspect | Type Test | Routine Test |

|---|---|---|

| Frequency | Once per design/rating | Every manufactured unit |

| Location | Accredited high-power laboratory | Factory floor |

| Duration | Weeks to months | Hours |

| Cost | $100,000–$500,000+ per design | Included in production cost |

| Destructive? | Often (samples may be sacrificed) | Non-destructive |

| Proves | Design meets rated claims | Unit free of manufacturing defects |

| Required documents | Laboratory certificate with oscillograms | Factory protocol with serial number |

The rated characteristics validated through type tests—voltage, current, breaking capacity—are detailed at https://xbrele.com/vacuum-circuit-breaker-ratings/. Understanding these specifications helps you verify that type test reports cover your actual requirements.

Include these specific requests in your RFQ to ensure complete test documentation:

For broader RFQ guidance beyond test documentation, the comprehensive checklist at https://xbrele.com/vcb-rfq-checklist/ covers commercial and technical specification elements.

[Expert Insight: Procurement Documentation Workflow]

- During bid evaluation, verify laboratory accreditation status before detailed technical review

- Request complete type test packages only from shortlisted suppliers—reduces administrative burden

- Correlate delivered nameplate serial numbers against routine test reports at site acceptance

- Archive all test documentation for warranty reference; disputes often surface 2–3 years post-installation

During bid evaluation, watch for these warning signs based on patterns observed across numerous procurement cycles:

Incomplete type test packages:

Questionable routine test practices:

Standards version confusion:

Vacuum interrupter origin ambiguity:

In one recent project, a supplier’s type test report showed 25 kA breaking capacity—but the tested unit contained vacuum interrupters from a manufacturer no longer used in production. The substitution rendered the type test invalid for the offered equipment. This gap only emerged during technical clarification; the initial quotation appeared compliant.

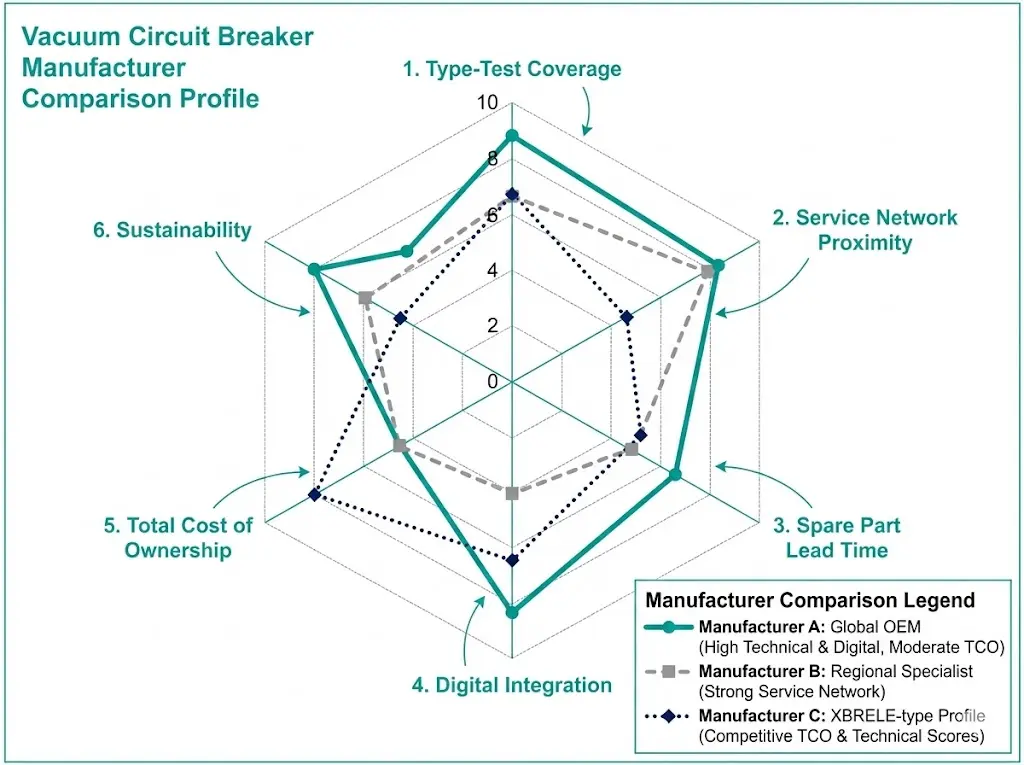

Not all test laboratories carry equal weight. The most recognized high-power testing facilities include KEMA (now DNV, Netherlands), CESI (Italy), XIHARI (China), and KERI (South Korea). For vacuum circuit breakers manufactured in Asia, XIHARI test reports are common and generally acceptable when the laboratory holds proper accreditation.

To verify laboratory credentials, consult the International Laboratory Accreditation Cooperation database at https://ilac.org/ilac-mra-and-signatories/. This confirms whether a laboratory operates under mutual recognition agreements accepted internationally.

Supplier evaluation indicators:

For manufacturers with verified type test programs, accessible documentation, and routine test transparency, explore the vacuum circuit breaker product range at https://xbrele.com/vacuum-circuit-breaker-manufacturer/.

Q1: What is the fundamental difference between type tests and routine tests for circuit breakers?

Type tests validate a circuit breaker design’s performance capability through rigorous laboratory examination of representative samples, while routine tests verify that each individual manufactured unit meets quality standards before shipment.

Q2: How many units undergo type testing versus routine testing?

Type tests examine one or more representative samples per design series, with results applying to all units of that design. Routine tests are mandatory for 100% of production units before factory release.

Q3: Can I request witnessed type tests for my specific project?

Yes, though this adds significant cost and schedule. Witnessed type testing is typically reserved for critical applications—generator breakers, main incomers, or custom ratings not covered by existing test programs.

Q4: What vacuum interrupter contact resistance range indicates acceptable routine test results?

Main circuit resistance typically falls between 20–80 μΩ for medium-voltage vacuum circuit breakers, varying with rated current. Values significantly above the manufacturer’s stated limit may indicate contact alignment or pressure issues.

Q5: Are type test reports from laboratories outside Europe and North America acceptable?

Laboratories holding ISO 17025 accreditation under ILAC mutual recognition arrangements are generally accepted internationally. XIHARI (China) and KERI (South Korea) are widely recognized for MV/HV equipment testing.

Q6: How long do type test results remain valid?

Type test validity continues indefinitely for unchanged designs. Significant modifications—different vacuum interrupters, altered mechanisms, changed insulation materials—require revalidation. Industry practice suggests reviewing reports older than 10 years.

Q7: What happens if routine tests reveal a defect after type testing passed?

Routine test failures indicate manufacturing issues with that specific unit, not design problems. The unit should be rejected, repaired, or replaced. Repeated routine test failures across multiple units may signal systemic production quality issues requiring investigation.