Need Full Specifications?

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

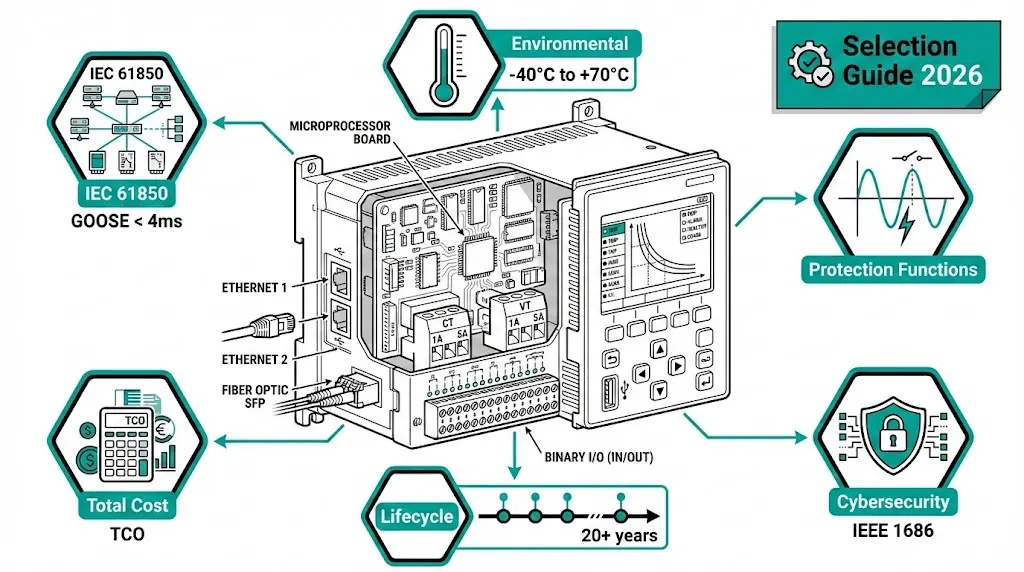

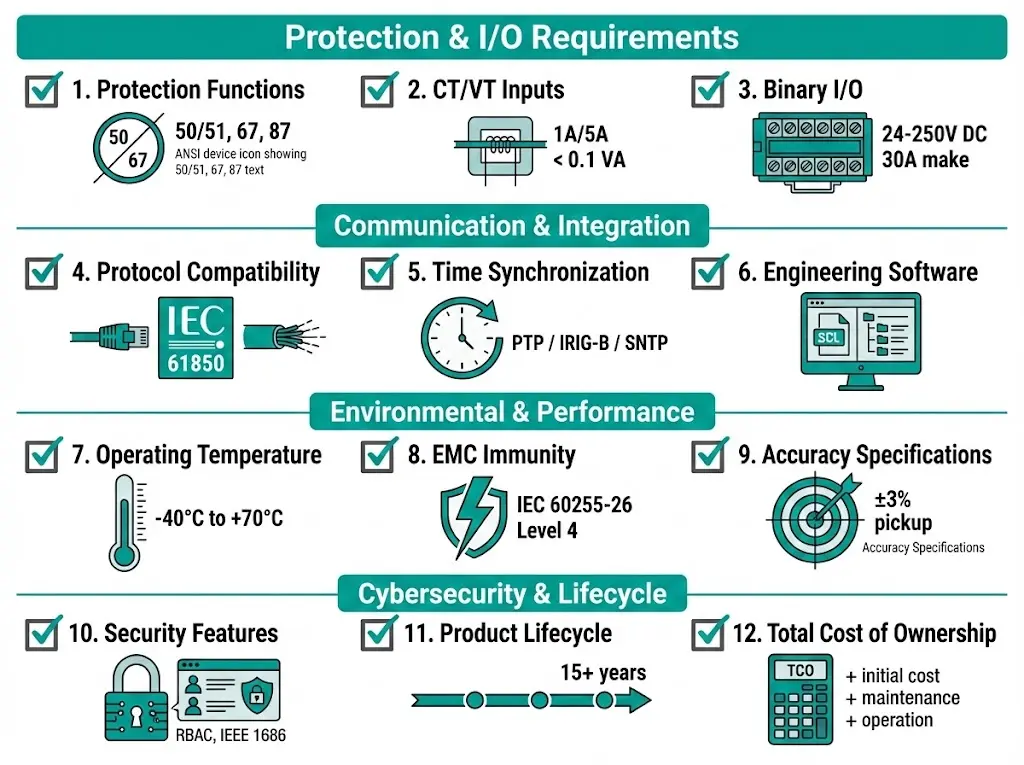

Protection relay manufacturers serving utility and medium-voltage switchgear must deliver proven expertise across fault detection, communication protocols, and grid integration. This guide evaluates leading manufacturers and provides a structured selection checklist for procurement teams specifying relays in the 3.3 kV to 36 kV range.

A protection relay functions as the decision-making core of every MV switchgear assembly. When a 15 kV distribution feeder experiences a phase-to-ground fault, the relay must detect abnormal current, apply time-current coordination logic, and issue a trip command—all within 20–40 milliseconds. This sequence completes before most operators notice the lights flicker.

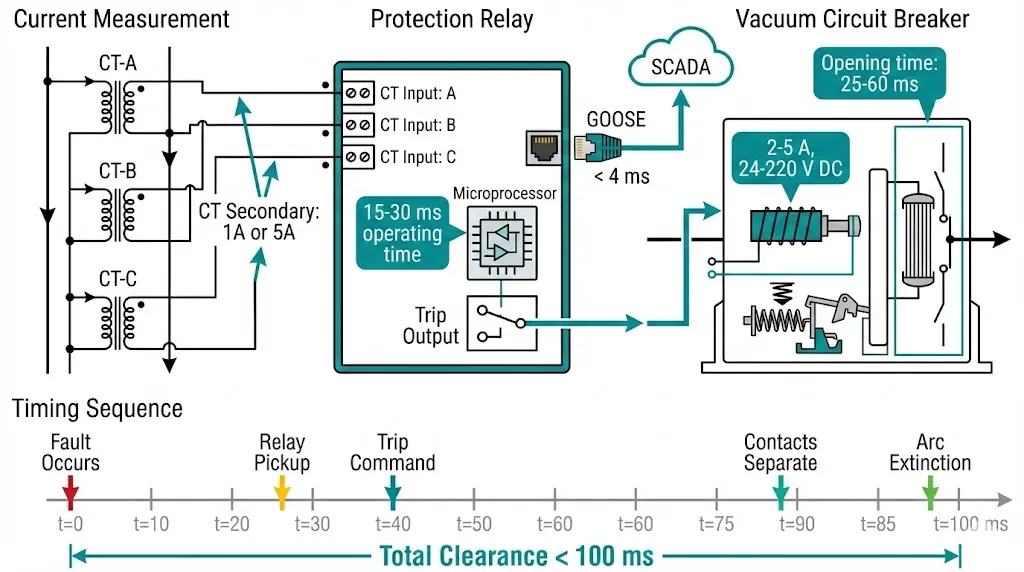

The relay’s output contacts energize the vacuum circuit breaker trip coil, releasing stored energy in the operating mechanism. Combined relay operating time (typically 15–30 ms for instantaneous elements) plus VCB mechanical opening time (25–60 ms) determines total fault clearance duration. Every millisecond matters: arc energy increases with the square of fault current multiplied by time.

Modern numerical relays have displaced electromechanical predecessors across 90% of new installations. These microprocessor-based devices integrate multiple protection functions, communication interfaces, and disturbance recording within a single platform. The current market transition centers on IEC 61850 adoption—manufacturers who invested early now offer mature implementations, while others retrofitted the protocol onto legacy hardware with varying success.

According to IEC 60255-151, protection relays must maintain timing accuracy of ±2.5% or ±10 ms (whichever is greater) to ensure predictable coordination between upstream and downstream devices. This standard establishes the baseline against which all manufacturers’ products should be evaluated.

Selecting the wrong manufacturer introduces risks beyond specification non-compliance: protection blind spots from inadequate algorithm implementations, nuisance tripping from poor noise immunity, integration failures preventing SCADA connectivity, and lifecycle disruption when spare parts become unavailable. The relay represents 3–8% of total switchgear cost but influences 100% of protection system reliability.

[Expert Insight: Field Deployment Observations]

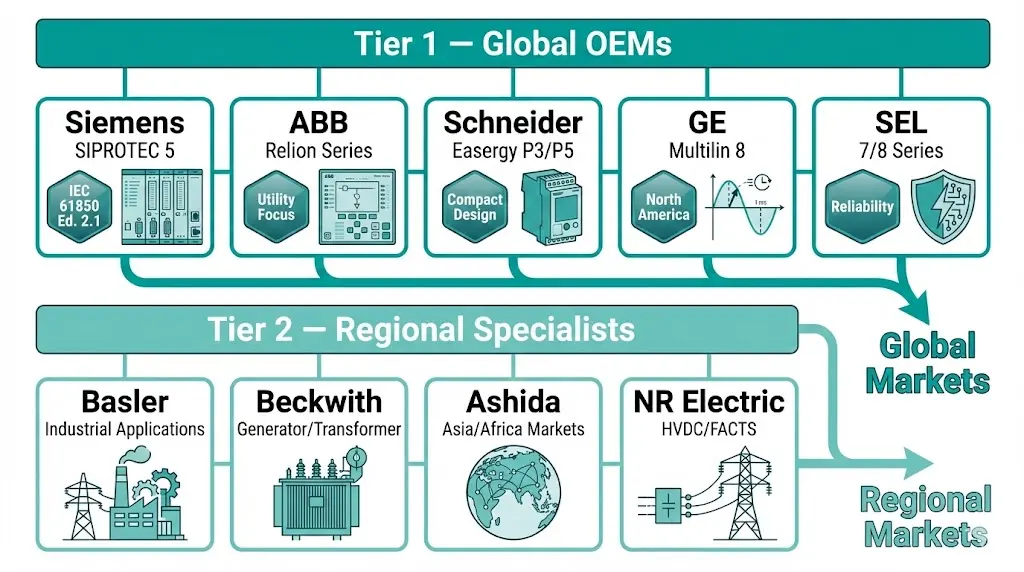

The protection relay market divides into global OEMs with comprehensive portfolios and regional specialists serving specific applications or geographies.

Tier 1 — Global OEMs

Siemens (SIPROTEC 5) offers modular architecture supporting configurations from simple overcurrent to complex busbar differential schemes. Native IEC 61850 Edition 2.1 support with GOOSE latencies under 4 ms suits process-bus applications. Field experience confirms robust performance in harsh industrial environments, though initial engineering effort for complex configurations exceeds some competitors.

ABB (Relion 615/620/630) covers feeder, transformer, and motor protection with consistent human-machine interface design. The Platform Engineering Tool streamlines IEC 61850 configuration, and ABB’s installed base in utility applications provides extensive reference projects. The REF615 has become a de facto standard in many utility specifications.

Schneider Electric (Easergy P3/P5) targets the 1–52 kV range with compact dimensions suitable for retrofit applications. Integration with the EcoStruxure platform appeals to operators seeking unified SCADA/protection architecture. Cybersecurity features align with IEC 62351 requirements.

GE Grid Solutions (Multilin 8 Series) maintains strong presence in North American utilities. The Universal Relay platform offers exceptional flexibility for complex protection schemes, and synchrophasor measurement integration positions these relays for wide-area protection applications.

SEL (Schweitzer Engineering Laboratories) dominates North American utility and industrial markets with relays engineered for extreme reliability. SEL’s conservative approach to new protocols means IEC 61850 implementations arrived later than competitors but with thorough validation. The SEL-751 feeder relay and SEL-487E transformer differential demonstrate their focus on protection security and dependability.

Tier 2 — Regional Specialists

Basler Electric serves industrial and small utility applications with straightforward configuration and competitive pricing. The BE1-851 overcurrent relay provides essential functions without complexity overhead.

Beckwith Electric specializes in generator and transformer protection. The M-3425A transformer relay offers comprehensive differential, overcurrent, and thermal protection—particularly strong in distributed generation interconnection.

Ashida Electronics (India) supplies numerical relays across Asia and Africa at price points 30–50% below Tier 1 manufacturers. Quality has improved significantly since 2018, though global service network depth remains limited.

NR Electric (China) has expanded beyond Chinese markets with competitive offerings, particularly in HVDC and FACTS protection. Utility adoption outside Asia requires evaluation of long-term support commitments.

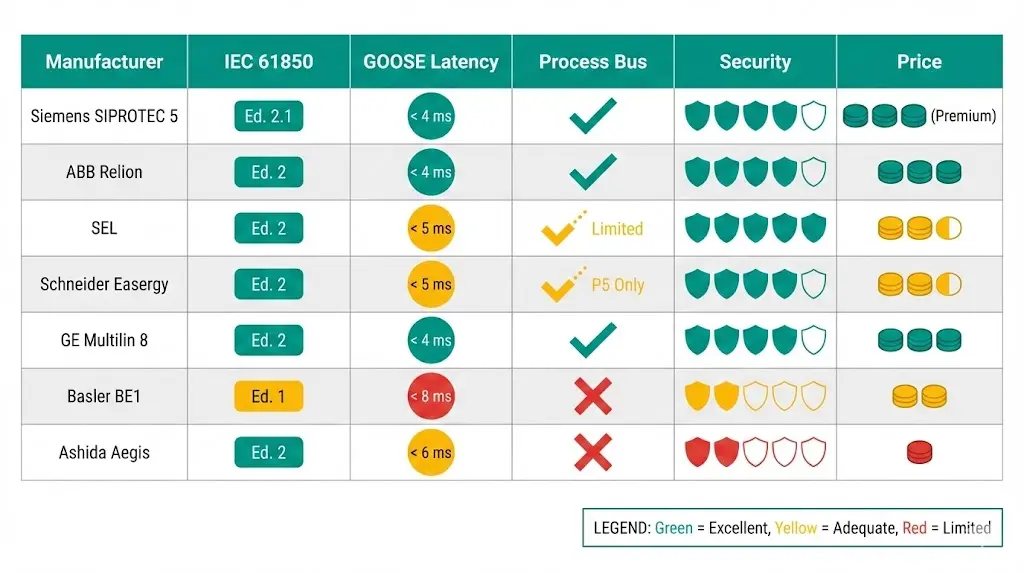

| Manufacturer | IEC 61850 Edition | GOOSE Latency | Process Bus | Cybersecurity | Price Position |

|---|---|---|---|---|---|

| Siemens SIPROTEC 5 | Ed. 2.1 | < 4 ms | Full | High | Premium |

| ABB Relion | Ed. 2 | < 4 ms | Full | High | Premium |

| SEL | Ed. 2 | < 5 ms | Limited | Very High | Mid-High |

| Schneider Easergy | Ed. 2 | < 5 ms | P5 Series | High | Mid-High |

| GE Multilin 8 | Ed. 2 | < 4 ms | Full | High | Premium |

| Basler BE1 | Ed. 1 | < 8 ms | No | Moderate | Mid |

| Ashida Aegis | Ed. 2 | < 6 ms | No | Moderate | Budget |

Communication protocol depth varies dramatically between manufacturers. Facilities implementing IEC 61850-compliant relays demonstrate measurable improvements in fault isolation speed, with peer-to-peer GOOSE messaging reducing zone interlocking times from 100–150 ms to under 4 ms compared to hardwired schemes.

For installations still using DNP3 or Modbus, verify that required protocol variants (DNP3 Secure Authentication, Modbus TCP) are supported without additional hardware modules.

When specifying protection relays for vacuum circuit breaker assemblies, verify trip coil compatibility. VCB trip coils typically require 2–5 A at 24–220 V DC sustained for 50–100 ms. Relay output contacts must exceed these demands with appropriate margin. For detailed VCB specification guidance, review the vacuum circuit breaker working principles that complement protection relay selection.

[Expert Insight: Commissioning Realities]

Protection relays installed in outdoor switchgear or industrial environments face conditions far harsher than climate-controlled relay rooms.

Standard commercial-grade relays specify -20°C to +55°C operation. Harsh environment variants extend to -40°C to +70°C but command 15–25% price premiums. Humidity tolerance at 95% RH non-condensing suits most installations, though tropical environments may require conformal coating on internal PCBs.

Vibration ratings per IEC 60255-21-1 separate into classes: Class 2 (0.5g, 10–150 Hz) suits most switchgear applications, while seismic zones require Class 3 certification. EMC immunity per IEC 60255-26 Level 4 represents the minimum for MV proximity—lower ratings invite nuisance operations from switching transients.

The relay-to-breaker interface determines protection scheme effectiveness. Modern relays offer direct trip coil supervision to detect open or shorted coils before a fault demands operation. Close supervision functions verify breaker-ready status, synchronism check for parallel sources, and anti-pumping logic—eliminating external interposing relays.

Arc-flash detection coordination achieves sub-cycle trip times when properly implemented. Light-sensitive sensors respond in under 2.5 ms; combined with relay operating time and VCB opening time, total arc duration stays below 100 ms for properly coordinated systems. Verify relay compatibility with arc-flash sensor manufacturers during specification.

Understanding vacuum circuit breaker manufacturer offerings helps specify relay timing margins appropriate for specific VCB operating mechanisms.

Most utilities adopt hybrid approaches balancing standardization benefits against competitive dynamics.

Unified configuration environments reduce engineering overhead. A standardized relay platform means one training program, one spare parts inventory, and one firmware management system. Support responsibility remains unambiguous when issues arise.

Competitive bidding maintains pricing discipline. Specialized vendors like Beckwith for transformer protection or SEL for generator applications offer depth that generalist portfolios may lack. Supply chain resilience improves when multiple qualified sources exist.

Standardize high-volume applications—feeder protection represents 60–70% of relay quantity in typical substations. Allow specialized vendors for complex applications where unique expertise justifies integration complexity. Establish clear interface specifications when mixing platforms.

Industrial facilities with limited protection engineering staff benefit most from single-source standardization. The engineering overhead of maintaining competency across multiple relay configuration tools often exceeds procurement savings from competitive bidding.

For comprehensive switchgear specification including protection devices and primary equipment, the switchgear component manufacturer guidance provides relevant procurement context.

XBRELE VCB assemblies accommodate major protection relay platforms including Siemens SIPROTEC, ABB Relion, SEL, and Schneider Easergy series. Pre-engineered mounting provisions support standard 19-inch rack and panel configurations without field modifications.

Protection relay timing coordinates with XBRELE VCB operating mechanisms during factory verification. Total fault clearance time—relay operating time plus VCB opening time—verifies below 100 ms for standard configurations. Arc-flash detection integration available for applications requiring sub-cycle protection.

Contact the XBRELE technical team to discuss protection relay integration requirements for your vacuum circuit breaker specifications.

External Reference: IEC 62271-106 — IEC 62271-106 standard for AC contactors

A: Numerical relays typically achieve 20–25 years of operational service, with manufacturers guaranteeing spare parts availability for 15 years minimum; actual lifespan depends on environmental conditions and firmware support continuation.

A: IEC 61850 enables multi-vendor interoperability through standardized GOOSE messaging, though interoperability testing during commissioning remains essential because implementation variations exist between manufacturers and product generations.

A: Industry practice recommends annual self-test log review and visual inspection, with comprehensive injection testing every 4–6 years based on criticality and environmental exposure.

A: Standard MV feeder protection requires 50/51 (phase overcurrent), 50N/51N (ground fault), and often 67/67N (directional overcurrent); transformer feeders typically add 87 (differential) and 49 (thermal) functions.

A: GOOSE provides Ethernet-based peer-to-peer signaling with latencies under 4–5 ms, while hardwired circuits use physical contact closure; critical applications often implement both methods for redundancy.

A: Utilities must verify compliance with IEEE 1686 and IEC 62351 authentication standards, role-based access control implementation, encrypted communication options, and security event logging capabilities before procurement approval.

A: Outdoor installations typically require extended temperature range (-40°C to +70°C), IEC 60255-21-1 Class 2 or higher vibration rating, and conformal coating options for humidity protection in tropical climates.