Need Full Specifications?

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

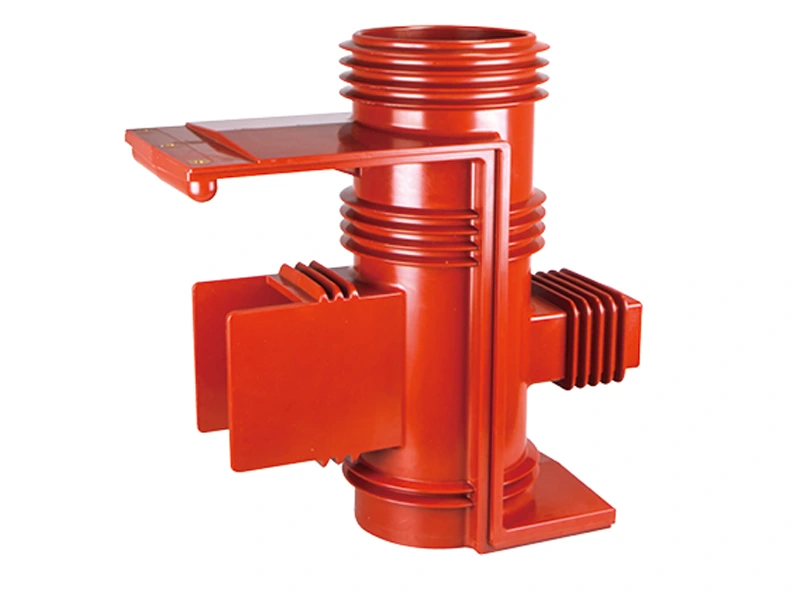

XBRELE’s Contact Boxes (also known as Switchgear Spouts or Static Contact Housings) are precision-molded using APG Epoxy Resin. Designed for KYN28 and UniGear panels, they ensure superior dielectric strength and PD < 5pC reliability for Medium Voltage systems.

XBRELE Contact Boxes (technically referred to as Switchgear Spouts or Static Contact Housings) serve as the critical insulation interface in air-insulated switchgear cabinets. They isolate the static contacts from the busbar compartment, ensuring safe operation for 12kV, 24kV, and 40.5kV distribution networks.

Manufactured using advanced APG (Automatic Pressure Gelation) technology with high-grade epoxy resin, our contact boxes offer superior dielectric strength and void-free mechanical stability. Unlike standard insulators, XBRELE’s epoxy contact boxes undergo rigorous testing to guarantee a Partial Discharge (PD) of < 5pC, preventing insulation breakdown over long operational cycles.

Designed for seamless compatibility, our CH3 series is the standard choice for KYN28A-12, KYN61, and UniGear ZS1 type armored removable AC metal-enclosed switchgear. Compliance with international standards, such as IEC 62271-1 High-voltage switchgear , ensures our medium voltage contact boxes meet global safety requirements for creepage distance and impulse withstand voltage (BIL).

For a complete range of insulators, bushings, and other switchgear components, please visit our main Switchgear Parts & Accessories pillar page .

12kV – 40.5kV epoxy resin contact boxes. Verified specifications for KYN28, KYN61, and JYN cabinets.

XBRELE contact boxes (switchgear spouts) are manufactured using advanced APG (Automatic Pressure Gelation) technology, ensuring superior dielectric strength and void-free insulation structure. Our products meet rigorous international standards for Partial Discharge and Impulse Withstand Voltage, providing reliable isolation for 12-40.5kV switchgear. For more insulation components, visit our Switchgear Parts pillar page .

Internal defects in epoxy insulation can lead to catastrophic failure. XBRELE contact boxes undergo strict PD testing to guarantee long-term reliability.

Designed to protect against lightning surges and switching transients, our epoxy contact boxes offer exceptional insulation margins.

Hidden cracks or poor bonding between copper inserts and epoxy can compromise safety. We use X-Ray technology to see what others can’t.

XBRELE combines advanced APG (Automatic Pressure Gelation) casting, precision mold design, and rigorous 100% routine testing to ensure that our contact boxes (switchgear spouts) deliver zero-defect insulation performance for 12-40.5kV medium voltage switchgear.

Our manufacturing line for epoxy resin components is optimized to eliminate internal voids, ensure high mechanical strength, and achieve precise dimensional tolerance for seamless KYN28/UniGear integration.

Molds are cleaned and pre-heated to precise temperatures. Copper inserts (static contact housings) are positioned with high accuracy to ensure alignment.

Epoxy resin is injected under vacuum and high pressure using APG technology. This eliminates air bubbles, ensuring high dielectric strength and < 5pC partial discharge.

Controlled curing cycles prevent internal stress and micro-cracking. Once cured, the contact box is demolded and inspected for surface finish.

Every batch undergoes X-Ray inspection to verify the bonding between the copper insert and the epoxy matrix, ensuring no hidden structural defects.

Routine tests for dimension, withstand voltage, and visual appearance are conducted before the switchgear components are packed for shipment.

All contact boxes are tested in accordance with IEC 60694 / GB 3906 standards to guarantee safety and reliability in critical power distribution networks.

XBRELE ensures rapid delivery of 12kV-40.5kV epoxy contact boxes and switchgear spouts to panel builders worldwide. We coordinate mold customization, secure packaging, and technical support for both OEM production and retrofit maintenance projects.

We maintain a strategic inventory of high-demand models like CH3-12/150 and CH3-12/250 to support urgent maintenance needs for KYN28/UniGear panels.

Beyond standard catalogs, XBRELE offers mold customization services to fit unique busbar geometries or specific medium voltage switchgear designs.

Epoxy resin requires careful handling to prevent surface chipping. We use reinforced packaging to ensure every contact spout arrives in perfect condition.

Technical answers regarding contact box selection, material properties, partial discharge limits, and compatibility with KYN28 and other medium voltage switchgear cabinets.