Need Full Specifications?

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

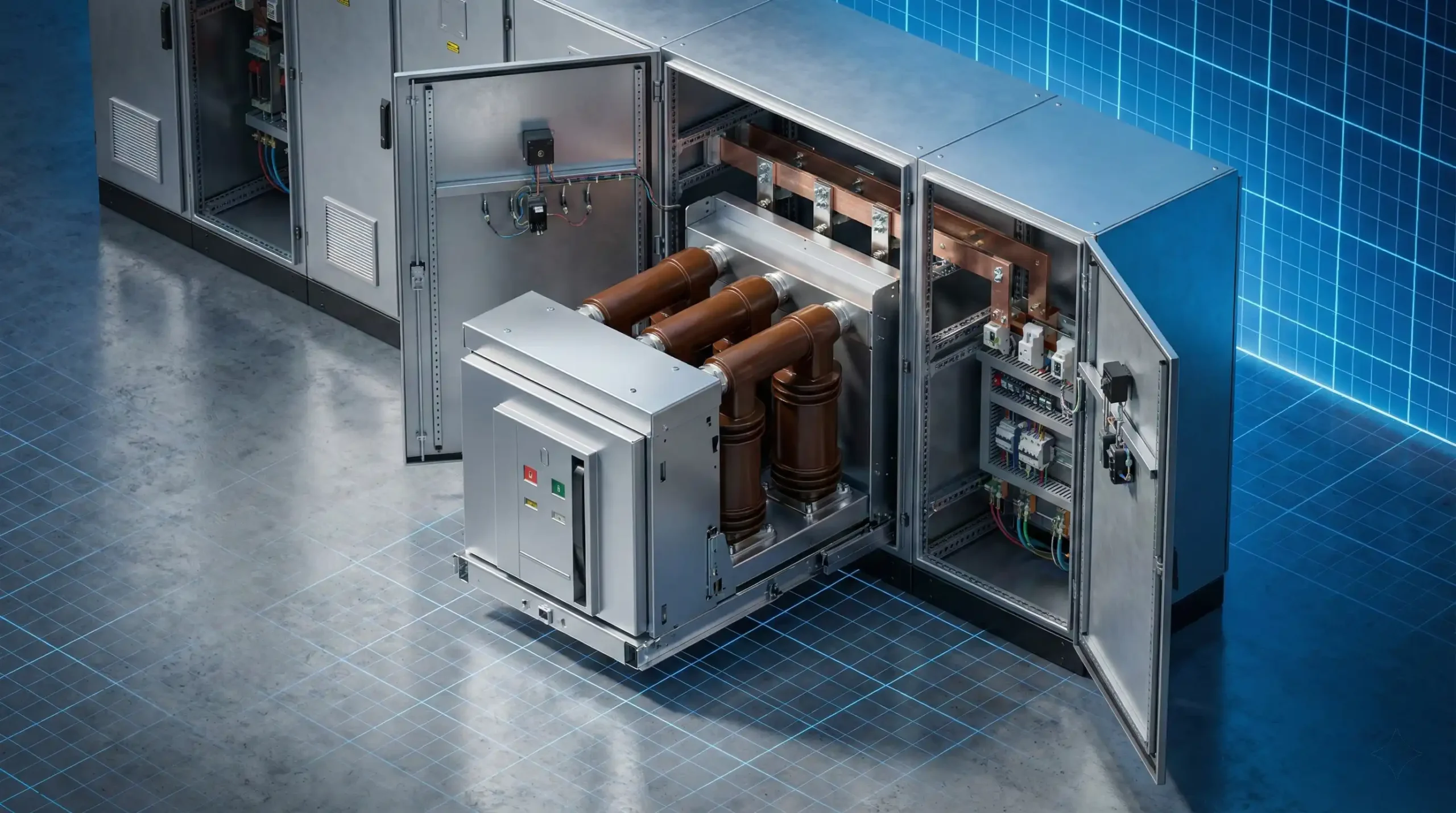

The Vacuum Circuit Breaker (VCB) is the globally accepted standard for medium-voltage switching, offering a maintenance-free and environmentally safe alternative to SF6 and Oil technologies.

Read time: ~8 mins | Target Audience: Electrical Engineers, EPCs, Utility Operators

Standard Reference: IEC 62271-100, IEEE C37.04

In the rapidly evolving landscape of medium-voltage (MV) power distribution, the “fit-and-forget” philosophy has become the gold standard for switching equipment. As power systems transition from centralized generation to complex, decentralized grids integrated with renewables, the demands on switchgear have shifted. It is no longer enough to simply interrupt a fault; modern breakers must handle frequent switching operations, withstand harsh environmental conditions, and minimize operational expenditure (OPEX).

Within this context, the vacuum circuit breaker (VCB) has decisively won the technological battle for voltage levels between 12 kV and 40.5 kV. Having displaced bulk oil and minimum oil breakers decades ago, VCBs are now systematically replacing SF₆ (Sulfur Hexafluoride) technology, driven by both superior technical performance and stringent environmental mandates against greenhouse gases.

For electrical engineers, plant managers, and EPC contractors, a superficial understanding of VCBs is insufficient. Correctly specifying equipment for a high-duty cycle steel mill, a critical data center, or a remote mining substation requires a deep grasp of the VCB’s internal physics, thermal behavior, and dielectric limits. This guide provides that engineering-level insight.

A vacuum circuit breaker is a medium- or high-voltage switching device where the core function—current interruption—occurs inside a hermetically sealed chamber known as a Vacuum Interrupter (VI). The “vacuum” typically refers to a pressure level below $10^{-4}$ Pa ($10^{-6}$ mbar).

To truly define a VCB from an engineering perspective, we must look at the physics of the arc. In other technologies, the arc is an ionized gas (plasma) formed from the surrounding medium (oil vapor, air, or SF₆). In a vacuum circuit breaker, there is no surrounding gas. The arc is purely a metal vapor plasma, generated by the vaporization of the contact material itself at the moment of separation.

Understanding what a VCB is requires understanding what it is not. See our detailed comparison on Vacuum Contactor vs Vacuum Circuit Breaker for panel selection nuances, but generally:

The VCB leverages the Mean Free Path principle: in a high vacuum, electrons can traverse the contact gap without colliding with gas molecules. Without collisions, an electron avalanche (breakdown) is difficult to initiate, giving vacuum gaps a dielectric strength far superior to air or SF₆ at small distances.

A vacuum circuit breaker is not just a “switch”; it is a precision-integrated system. Reliability depends on the synergy between the vacuum interrupter, the insulation, and the mechanism.

The heart of the VCB is the vacuum interrupter. Its integrity is non-negotiable.

The Achilles’ heel of early designs, the bellows is a stainless steel, accordion-like tube that allows the moving contact to travel typically 6mm to 20mm without breaking the vacuum seal. Modern hydro-formed bellows are rated for M2 class endurance (10,000 to 30,000 mechanical operations), far exceeding the lifespan of the primary system.

Because vacuum interrupters have a very short stroke (distance) compared to SF₆ or Oil breakers, the mechanism must deliver high force over a short distance with precise damping.

This includes the anti-pumping relay (preventing the breaker from cycling open-close-open on a sustained fault), trip coils, and auxiliary contacts for SCADA feedback.

The operation is a race against time—specifically, a race between the Transient Recovery Voltage (TRV) rising across the contacts and the Dielectric Recovery of the vacuum gap.

Current flows through the fixed and moving contacts. The contact resistance is extremely low (measured in micro-ohms, $\mu\Omega$). The external mechanism applies immense pressure (contact spring force) to prevent the contacts from popping open due to electrodynamic forces during a short circuit.

Upon receiving a signal from the protection relay, the latch releases. The opening springs pull the moving contact downward. The separation speed is critical—too slow, and the arc burns too long; too fast, and the bellows may fracture.

(Note: Please refer to the diagram in Section 3 for the detailed component breakdown. An exploded view is critical for understanding the mechanical linkage).

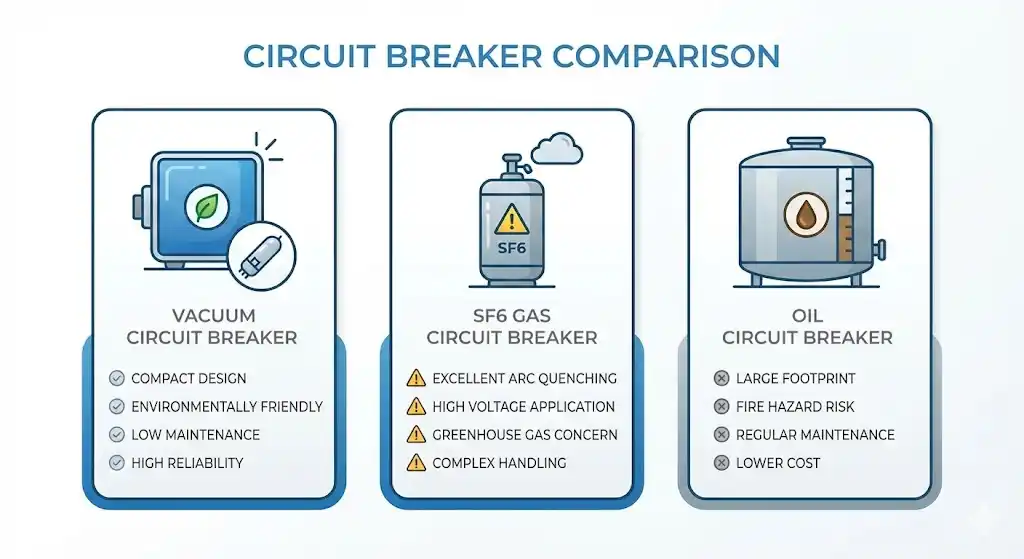

The comparison chart below highlights why VCB is the choice for MV, while SF₆ is reserved for HV/EHV.

| Feature | Vacuum Circuit Breaker (VCB) | SF₆ Circuit Breaker | Air Circuit Breaker (ACB) |

|---|---|---|---|

| Arc Quenching Medium | Vacuum ($<10^{-6}$ bar) | Sulfur Hexafluoride Gas | Atmospheric Air |

| Number of Operations | High (10,000 – 30,000) | Medium (2,000 – 5,000) | Low |

| Maintenance | Sealed for Life | Gas Pressure Checks Required | Arc Chute Cleaning |

| Size / Footprint | Very Compact | Compact | Large / Bulky |

| Fire Hazard | None | Low (Non-flammable gas) | Moderate (Ionized air) |

| Environmental | Green (Zero Emissions) | High Impact (GHG) | Neutral |

| Restrike Risk | Very Low (High recovery speed) | Low | Medium |

Utilities use VCBs for distribution feeders (11kV to 33kV). The high reliability means they can be installed in remote unmanned substations.

This is a VCB stronghold. Motors require frequent starting and stopping. VCBs can handle thousands of switching cycles without contact maintenance.

Electric Arc Furnaces (EAF) are the ultimate torture test, requiring up to 100 switching operations per day. Only VCBs (often with magnetic actuators) can survive this duty cycle. The hermetically sealed contacts are also immune to the conductive coal dust and humidity often found in mines.

Smart grids require automated switching at the distribution level.

1. What is the “Current Chopping” phenomenon? Because vacuum is such an efficient interrupter, it can sometimes extinguish the arc before the natural current zero (e.g., at 3A or 4A instead of 0A), specifically when switching small inductive currents (like unloaded transformers). This sudden “chop” traps magnetic energy, creating high transient over-voltages. While modern CuCr contact materials minimize this, surge arresters are recommended for sensitive loads.

2. How do I test a Vacuum Circuit Breaker? You cannot check the vacuum visually.

3. Why do VCBs have a “spring charging” motor? The closing spring requires significant force to compress. A small electric motor charges this spring automatically after every closing operation, ensuring the breaker is always ready to perform an “Open-Close-Open” (O-C-O) cycle immediately if a fault occurs.

4. Can VCBs be used for DC applications? Generally, no. VCBs rely on the AC current zero to extinguish the arc. In a DC circuit, current never crosses zero naturally. Special “counter-current injection” circuits are needed to use vacuum technology for DC breaking.

5. What happens if the bellows fail? If the bellows develop a microscopic crack, the vacuum is lost. The interrupter will fail to clear a fault, likely resulting in a catastrophic explosion of the pole unit due to the uncontained arc. This is why mechanical endurance (M2 class) is a critical specification.

6. Are VCBs suitable for capacitor bank switching? Yes, they are excellent for this (Class C2 rating) due to high dielectric strength. However, precise point-on-wave switching or pre-insertion resistors are sometimes used to limit inrush currents.

The vacuum circuit breaker has evolved from a niche technology to the backbone of modern medium-voltage infrastructure. Its dominance is not accidental—it is the result of inherent physical advantages: a metal vapor arc that extinguishes at current zero, a recovery speed that outpaces grid transients, and a sealed design that ignores dirty environments.

However, not all VCBs are created equal. The quality of the brazing, the purity of the CuCr alloy, and the precision of the operating mechanism determine whether a breaker lasts 5 years or 30.

Don’t compromise on grid reliability. For critical infrastructure projects, working with an experienced manufacturer is essential. XBRELE specializes in high-end vacuum switching technology tailored for demanding industrial and utility applications.

Ready to specify your next project? Contact XBRELE’s engineering team to discuss vacuum circuit breaker selection, OEM customization, or consult our vacuum circuit breaker manufacturer page for detailed technical specifications.

Explore the critical safety benefits of JCZ vacuum contactors in hazardous mining environments. This guide covers arc suppression in sealed chambers, fire risk reduction, and high-frequency motor control[cite: 11, 13, 97].

Download Mining Safety Guide