Need Full Specifications?

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

See 11kV transformer price ranges, key cost factors, and tips to select the best unit for your project. Compare oil-immersed vs dry-type and save on total costs.

You might wonder what the 11kv transformer price looks like today. Right now, you can find options starting at $800 for smaller units, but some high-end models reach $60,000. The 11kv transformer price changes a lot based on what you need. If you pick a higher kVA rating, expect a jump in cost since more copper and steel go into bigger units. The cooling type also matters—forced-air or oil systems push the 11kv transformer price up because they need extra fans, pumps, and controls. Want a tap changer? That feature alone can add $10,000 to $30,000. When you compare offers, you’ll see the 11kv transformer price depends on these choices.

11kV transformer prices range from $800 to $60,000, depending on size and features.

Consider your specific needs to avoid overspending on unnecessary transformer capacity.

Oil-immersed transformers are generally cheaper than dry-type models, but check local safety regulations.

Customization options can significantly affect the price; choose features that align with your project requirements.

Always request a detailed quote from suppliers to understand the total cost, including installation and maintenance.

Efficiency matters; investing in a high-efficiency transformer can save money on energy bills over time.

Look for reputable brands to ensure reliability and support, even if they come at a higher initial cost.

Plan for future power needs to avoid costly upgrades later; a slightly larger transformer can be more economical in the long run.

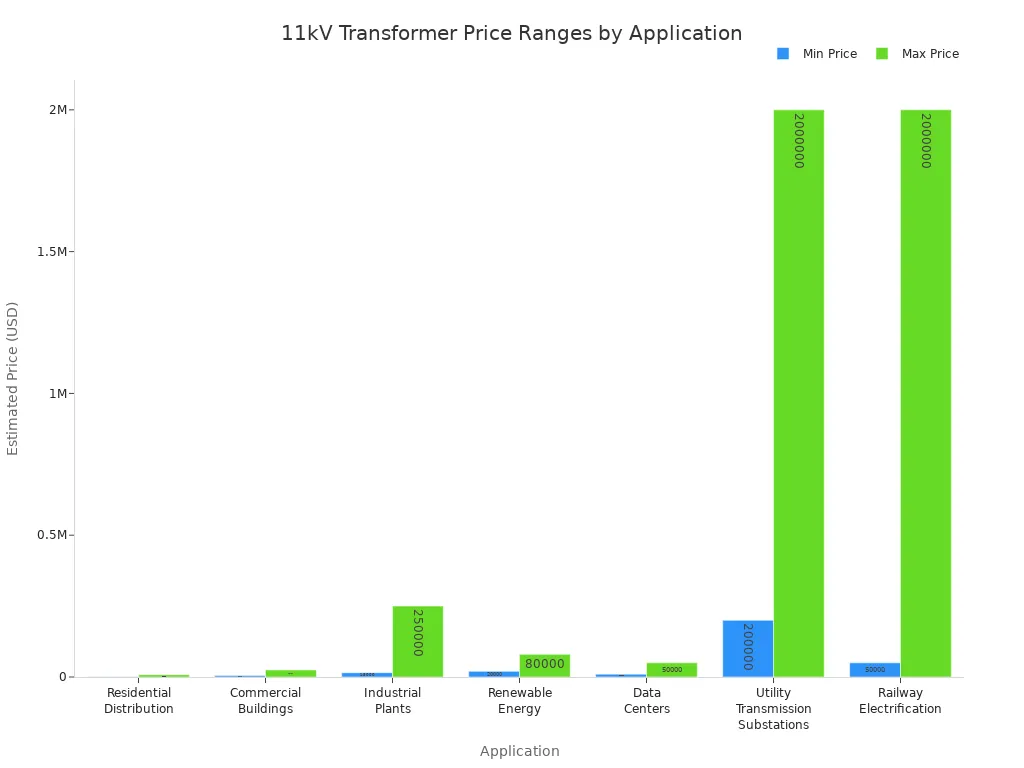

When you start looking at transformer pricing, you’ll notice a wide range. The average price ranges of transformers depend on where you plan to use them. For example, a small unit for a residential area might cost just $1,000. If you need a transformer for a big industrial plant, the price can jump to $250,000 or more. The transformer price overview below shows how much you might pay for different applications:

Application | Estimated Price Range (USD) |

|---|---|

Residential Distribution | $1,000 – $8,000 |

Commercial Buildings | $5,000 – $25,000 |

Industrial Plants | $15,000 – $250,000+ |

Renewable Energy | $20,000 – $80,000 |

Data Centers | $10,000 – $50,000+ |

Utility Transmission Substations | $200,000 – $2,000,000+ |

Railway Electrification | $50,000 – $2,000,000+ |

You can see that the price for a transformer in a 11kv substation is much higher than for a small building. The cost goes up as the application gets bigger and more complex.

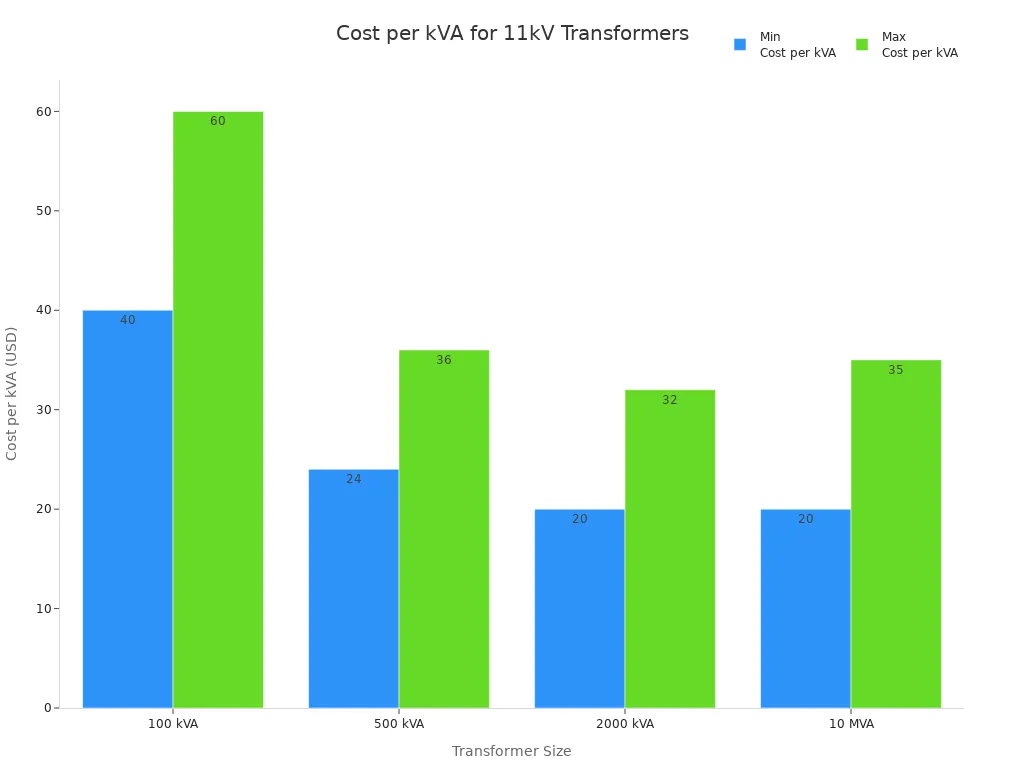

The size of the transformer makes a big difference in price. If you need a 100 kVA unit for a small 11kv substation, you might pay between $4,000 and $6,000. For a 500 kVA transformer, the price jumps to $12,000–$18,000. If you need a 2000 kVA transformer, expect to pay $40,000–$65,000. The cost per kVA drops as the size increases, so bigger units give you better value for each kVA.

Transformer Size | Approx. Price Range | Cost per kVA |

|---|---|---|

100 kVA | $4,000 – $6,000 | $40 – $60 |

500 kVA | $12,000 – $18,000 | $24 – $36 |

2000 kVA | $40,000 – $65,000 | $20 – $32 |

10 MVA | $200,000 – $350,000 | $20 – $35 |

If you want to save money, you should think about your actual needs for the 11kv substation. Buying a bigger transformer than you need will raise your cost without giving you extra benefits.

You’ll find two common types of electric transformers for a 11kv substation: oil-immersed and dry-type. The cost differences between oil-immersed and dry-type transformers can be pretty big. Oil-immersed transformers usually cost less. For example, a 500 kVA oil-immersed unit might cost $12,000, while a dry-type unit of the same size could reach $18,000 or more. Dry-type transformers use special insulation and cooling, which adds to the price.

Tip: If you need a transformer for a place with strict fire safety rules, you might have to pick a dry-type model even though the cost is higher. Always check your local codes before you buy.

The cost differences between oil-immersed and dry-type transformers also show up in maintenance. Oil-immersed units need regular oil checks and sometimes oil changes. Dry-type transformers need less maintenance, but their upfront price is higher. If you want to keep your long-term cost low, you should think about both the purchase price and the maintenance cost.

When you compare transformer pricing, don’t forget to look at extra features. Adding an on-load tap changer (OLTC) or a de-energized tap changer (DETC) can increase the price by $10,000–$30,000. These features help you adjust voltage in your 11kv substation, but they add to the total cost.

If you want the best deal, always ask for a full transformer price overview from your supplier. Make sure you know what’s included in the price, like installation, delivery, and warranty. That way, you won’t get surprised by extra costs later.

When you start comparing transformer prices, the power rating stands out as one of the key factors affecting transformer cost. The power rating tells you how much electrical load your transformer can handle. If you need a transformer for a small 11kv substation, you might look at units with lower kVA ratings. These usually cost less. As you move up to higher power ratings, the price goes up quickly. Bigger transformers need more copper, steel, and insulation, which drives up the cost.

Here’s a quick look at how power rating affects price:

Transformer Type | Power Rating | Approximate Price Range (USD) |

|---|---|---|

Low-Voltage Dry-Type | 5–100 kVA | $1,000 – $10,000 |

Medium-Voltage Dry-Type | 10–1,000 kVA | $5,000 – $30,000 |

Oil-Immersed Distribution | 20–3,000 kVA | $1,000 – $50,000 |

Outdoor Pad-Mounted | 100–9,500 kVA | $1,000 – $100,000 |

Power Transformer | 5–500 MVA | $200,000 – $5,000,000+ |

If you choose a higher power rating than you need, you’ll pay more without getting extra value. Always match the transformer size to your actual load. This helps you avoid unnecessary cost and keeps your 11kv substation running efficiently.

Cooling type is another big factor when you look at transformer prices. You’ll see two main cooling systems: oil-immersed and dry-type. Oil-immersed transformers use oil to keep the unit cool. These usually cost less up front. Dry-type transformers use air or special insulation for cooling. They cost more because they need advanced materials and extra safety features.

If your 11kv substation sits in a place with strict fire codes, you might need a dry-type transformer. This will raise your cost. Oil-immersed units work well in outdoor settings and cost less, but they need regular oil checks and maintenance. Dry-type units cost more at first, but you save on maintenance over time.

Tip: Always check local safety rules before you pick a cooling type. The right choice can save you money and trouble later.

The materials inside your transformer play a huge role in both price and efficiency. Copper and aluminum are the two main choices for windings. Copper costs more, but it gives you better conductivity and higher efficiency. Aluminum costs less, but it’s not as efficient.

Winding Material | Cost Impact | Conductivity | Efficiency |

|---|---|---|---|

Copper | Higher | Excellent | High |

Aluminum | Lower | Good | Moderate |

The core material also affects cost. High-quality silicon steel reduces energy losses, but it costs more. Grain-oriented electrical steel (GOES) gives you better efficiency, but you’ll pay a premium. Amorphous steel can cut no-load losses by up to 80%, but it’s the most expensive option.

High-quality silicon steel lowers core losses but increases cost.

Grain-oriented electrical steel boosts efficiency at a higher price.

Amorphous steel slashes no-load losses but costs the most.

If you want your 11kv substation to run efficiently, you might choose better materials. This will raise the price, but you’ll save on energy bills over time. When you look at factors that influence electric transformer price, always consider the trade-off between upfront cost and long-term savings.

When you look at the price of a transformer for your 11kv substation, the tap changer makes a big difference. A tap changer lets you adjust the output voltage. This helps you keep your system stable when the input voltage changes. You can choose between two main types: on-load tap changer (OLTC) and de-energized tap changer (DETC).

OLTC: You can change the voltage while the transformer is running. This feature adds a lot to the cost. You might see the price go up by $10,000 to $30,000 just for this option.

DETC: You have to turn off the transformer to adjust the voltage. This type costs less, but it is not as flexible.

If your 11kv substation needs to handle changing loads or you want to avoid downtime, you should pick an OLTC. The extra price pays off in better control and less risk of power problems. If your system runs at a steady load, a DETC can save you money. Always ask your supplier about the tap changer type because it is one of the key factors affecting transformer cost.

Tip: Don’t forget to check if the tap changer comes with extra controls or monitoring systems. These can add to the total cost, so make sure you know what’s included in the price.

You might think standards and certifications are just paperwork, but they have a real impact on both cost and price. When you buy a transformer for your 11kv substation, you want to make sure it meets the right standards. This keeps your system safe and helps you avoid problems with local rules.

Transformers that meet international standards like IEC, ANSI, IEEE, or ISO usually cost more. The reason is simple: the manufacturer has to follow strict quality checks and do extra testing. For example, a project that needed both IEC and ANSI standards saw the price go up by about 15% compared to a standard model. If you need special certifications like UL or CSA, the cost can rise even more.

Here’s a quick look at how different certifications affect the price and what you get in return:

Certification Type | Cost Impact | Benefit |

|---|---|---|

Basic (e.g., ISO 9001) | Minimal | Quality assurance |

IEC/ANSI Compliance | Moderate | International acceptance |

Special (e.g., UL, CSA) | Significant | Market-specific entry |

Custom Requirements | High | Meeting unique project needs |

If your 11kv substation is part of a global project or needs to meet special rules, you should expect a higher price. Always ask your supplier which certifications are included. This is one of the key factors affecting transformer cost that many buyers overlook.

The brand you choose for your transformer can change the price a lot. Well-known global brands charge more, but you get proven designs and strong support. Regional brands offer a balance between cost and performance. Local or unknown brands might save you money, but you could face risks with quality or after-sales service.

Here’s how different brands affect the price:

Manufacturer Category | Price Influence | Reason |

|---|---|---|

Tier 1 (Global OEMs) | +10–20% | Proven design reliability and documentation |

Tier 2 (Regional Manufacturers) | ±0% | Balanced cost and performance |

Unknown / Local Brand | –20–30% | Uncertain design and test history |

If your 11kv substation is critical to your business, you might want to pay more for a trusted brand. This can save you from costly breakdowns or delays. If you have a tight budget, a regional brand can give you good value without the high price. Always check the manufacturer’s track record and ask for references before you decide. The brand is not just a name—it can affect the total cost and long-term reliability of your transformer.

When you start shopping for an 11kV transformer, you’ll notice that customization plays a huge role in the final price. You don’t just pick a transformer off the shelf. You get to choose features that fit your project, and each choice can change the cost.

Let’s break down some common customization options and how they affect what you pay:

Customization Option | What It Means For You | How It Impacts Price |

|---|---|---|

Open or Enclosed Styles | You can pick a transformer with an open frame or a fully enclosed case. Enclosed styles protect against dust and weather, but they cost more. | Price goes up with more complex enclosures. |

Double-wound and Auto-wound | You might need a transformer with special winding types, like double-wound or auto-wound. These change how the transformer handles voltage and current. | Different winding designs can raise the price. |

Step-up Voltage | Sometimes you need a custom voltage, like boosting from 110V or 240V up to 11kV. Special voltage ratings mean extra engineering. | Higher voltage ratings increase the cost. |

Resin Encapsulated Coils | If you want extra protection, you can ask for resin encapsulated coils. These help the transformer handle high voltages and tough environments. | Expect to pay more for this feature. |

Air-cooled with Fans | For bigger transformers, like 1000kVA units, you can add air cooling with fans. This keeps things running smoothly, especially in hot spots. | Cooling systems add to the overall price. |

Cast Resin Transformers | You can choose cast resin models for better reliability and longer life. These are great for places with strict safety rules. | Premium pricing for advanced features. |

You might wonder why these options matter. Custom features help your transformer work better in your specific setup. For example, if your site gets a lot of dust or rain, an enclosed style keeps your equipment safe. If you need to boost voltage for a special machine, a step-up transformer does the job.

Tip: Always ask your supplier about customization. You don’t want to pay for features you don’t need, but you also don’t want to miss out on something important for your site.

Here’s a quick checklist to help you decide:

Do you need extra protection from weather or dust?

Are you working with special voltage requirements?

Is reliability or long service life a top priority?

Will your transformer run in a hot environment?

If you answer “yes” to any of these, customization makes sense. Just remember, every upgrade adds to the price. You get more value, but you also need to balance your budget.

Choosing the right options helps you avoid problems down the road. You get a transformer that fits your needs, runs efficiently, and lasts longer. Take your time, ask questions, and make sure you understand what each feature does. That way, you’ll get the best deal for your 11kV substation.

If you need a transformer for a small project or a compact substation, you might look at the 100 kVA 11kV model. The electric transformer price for this size usually sits between $4,000 and $6,000. You get a reliable unit that handles basic loads for small buildings or local distribution. The price depends on the cooling type and the materials inside. Oil-immersed models cost less, while dry-type units push the electric transformer price higher. You might see extra costs if you want special features like tap changers or advanced monitoring. Always check what’s included before you buy. Some suppliers add delivery and installation to the electric transformer price, but others leave those out.

Tip: If you want to keep your budget in check, ask for a breakdown of the electric transformer price. This helps you spot hidden fees and compare offers more easily.

You might need a bit more power for a medium-sized building or a small industrial site. The electric transformer price for a 250 kVA 11kV unit covers a wide range. Here’s what you can expect:

The average electric transformer price for a 250 kVA 11kV model runs from $1,000 to $20,000.

Oil-immersed transformers usually sit at the lower end of the price range.

Dry-type and customized models push the electric transformer price higher.

Accessories like tap changers, special enclosures, or advanced controls add to the price.

You should always match the transformer size to your actual load. If you pick a bigger unit than you need, you pay more without getting extra value. The electric transformer price reflects not just the size, but also the features and brand.

If your project needs even more power, you might look at the 500 kVA 11kV transformer. The electric transformer price for this size depends on the type and any custom options. Here’s a quick table to help you compare:

Transformer Type | Estimated Price Range (USD) |

|---|---|

Oil-Immersed 500kVA | $6,000 – $12,000 |

Dry-Type 500kVA | $8,000 – $15,000 |

Amorphous Core 500kVA | $10,000 – $18,000 |

Customized (with accessories) | $12,000 – $25,000 |

You see a big jump in electric transformer price when you choose dry-type or amorphous core models. These offer better safety and lower losses, but you pay more up front. If you need special accessories, the price climbs even higher. Always ask your supplier for a detailed quote. This helps you understand the electric transformer price and avoid surprises later.

Note: The electric transformer price for 500 kVA units can change based on market demand and material costs. If you want the best deal, compare several suppliers and check what’s included in the price.

If you need a serious boost in power for your project, a 1000 kVA 11kV transformer might be just what you’re looking for. These units work well for large commercial buildings, factories, or even small substations. You’ll notice the price can swing quite a bit, depending on what you want and which brand you choose.

Here’s what you can expect when you start shopping for a 1000 kVA 11kV transformer:

The price usually falls between $8,000 and $25,000.

Dry-type transformers cost more than oil-filled ones. If you need extra fire safety or want less maintenance, you’ll probably lean toward dry-type, but you’ll pay a premium.

Well-known brands like ABB, Schneider Electric, or Siemens charge more. You get better support and proven reliability, but the price tag reflects that.

Custom features, like special enclosures, advanced monitoring, or extra cooling fans, will push the price higher.

Copper windings add to the cost. Aluminum windings save you money, but copper gives you better efficiency and longer life.

Don’t forget about the extras. Shipping, taxes, and installation can add another 10–30% to your total bill. Always ask your supplier for a full quote so you know exactly what you’re paying for.

Tip: If you want to keep costs down, stick with standard features and compare a few brands. Sometimes, a regional manufacturer offers great value without the big-name markup.

You might wonder how the price of a 1000 kVA transformer stacks up against other types. Here’s a quick table to help you compare different 11kV transformer options. This can make your decision a lot easier:

Transformer Type | Price Range (USD) |

|---|---|

Oil-Immersed | $1,200 – $1,800 |

Dry-Type Resin | $1,600 – $2,500 |

With Accessories | Up to $3,000 |

Keep in mind, these prices reflect smaller capacity units. As you move up to 1000 kVA, the numbers climb, but the same trends hold true. Oil-immersed models usually cost less, while dry-type and units with extra features cost more.

When you compare prices, always look at what’s included. Some suppliers bundle in accessories, delivery, or even installation. Others list those as separate charges. If you want the best deal, line up all the details side by side. That way, you can spot hidden costs and make a smart choice for your project.

Note: The cheapest option isn’t always the best fit. Think about your long-term needs, safety requirements, and how much downtime you can handle. Sometimes, spending a little more up front saves you headaches later.

You want to make sure your transformer matches your project. This step is one of the key considerations when purchasing a transformer. If you skip it, you might end up with equipment that costs more than you need or doesn’t work well. Here are some practical tips for a smart purchase:

Figure out your load requirements. How much power do you need every day? Will your demand grow in the future?

Decide on the transformer type. Oil-immersed or dry-type? Each has its own cost and maintenance needs.

Check voltage levels. Your transformer must match your supply and output voltages.

Think about environmental conditions. Will your transformer sit outdoors or indoors? Is the area dusty, humid, or hot?

Look at efficiency and loss considerations. Higher efficiency means lower energy bills.

Make sure your transformer meets safety certifications and standards. This keeps your equipment procurement process smooth and avoids trouble later.

If you want to know how to choose the right transformer, start with these points. You’ll avoid costly mistakes and get the best value for your total installed cost.

Efficiency plays a huge role in the power transformer cost over time. You might pay more up front for a high-efficiency model, but you save money every month on your energy bill. Efficient transformers generate less heat, so you spend less on cooling and maintenance. They also last longer, which means fewer replacements and less downtime.

Here’s a quick look at how efficiency and losses affect your total installed cost:

Key Point | Explanation |

|---|---|

Efficiency Impact | Higher efficiency reduces energy losses, leading to lower operational costs over the transformer’s lifespan. |

Cooling Needs | Transformers with lower losses require less cooling, further decreasing energy consumption and maintenance costs. |

Initial Investment vs. Long-term Savings | Although efficient transformers may have a higher initial cost, the long-term savings from reduced operational costs make them more cost-effective. |

Life Cycle Cost Evaluation | Evaluating life cycle costs rather than just initial costs can yield significant savings over the transformer’s expected lifespan of 30 to 40 years. |

You want a transformer that runs cool and lasts for decades. Efficiency not only cuts your energy costs, but also helps you meet environmental rules. If you focus on life cycle cost, you’ll see that the best tips for reducing transformer costs often involve spending a little more up front for big savings later.

Space and installation matter more than you might think. If you don’t plan for these, your equipment procurement can get expensive fast. You need to know the size and weight of your transformer before you buy. This helps you avoid surprises during installation and commissioning.

Here’s a table showing what to check:

Aspect | Description |

|---|---|

Dimensions | Get accurate front, side, and top views to plan your space. |

Weight | Make sure your building or platform can support the transformer. |

Terminal Layouts | Check HV and LV terminal layouts for safe and easy wiring. |

Cooling Ducts | Look for designs that allow natural or forced air circulation. |

Maintenance Reference | Make sure the core and coil assembly are marked for easy maintenance. |

Support Frame | Confirm lifting lugs and support frames for safe transport and installation. |

Bushing Connections | Identify bushing connections for electrical safety. |

Electrical Configuration | Review the vector group diagram to understand the setup. |

If you want the best tips for reducing transformer costs, plan your installation and commissioning early. This keeps your total installed cost low and helps you avoid delays. Always ask your supplier for detailed drawings and specs before you finalize your equipment procurement.

When you buy an 11kV transformer, you want more than just the equipment. After-sales service and warranty can make a big difference in your experience and your budget. Here’s why you should pay close attention:

A strong warranty helps you avoid big repair bills. If something goes wrong early, you won’t have to pay out of pocket.

Good after-sales support gives you peace of mind. You know help is available if you run into trouble.

On-site troubleshooting and installation guidance can save you time and prevent mistakes.

Service and maintenance packages help you plan your costs. You won’t get hit with surprise expenses.

A solid warranty can even boost the resale value of your transformer if you ever upgrade or sell.

Tip: Always ask what the warranty covers and how long it lasts. Some suppliers offer only basic coverage, while others include spare parts and labor.

Choosing a supplier with full after-sales support means you get help when you need it most. This support protects your investment and keeps your transformer running smoothly.

Not all transformer suppliers are the same. You want to compare them carefully before you decide. Price matters, but it’s not the only thing to look at. Here’s a table to help you see what really counts:

Criteria | Key Considerations | Impact on Value |

|---|---|---|

Price | Base unit cost, transport, taxes | Initial expenditure |

Technical Compliance | Meets IEC 60076 / IEEE C57 standards | Safety and performance |

Warranty & Service | Duration, coverage, spare parts availability | Maintenance cost and uptime |

Delivery Times | Realistic production and shipping timelines | Project completion timeline |

Shipping Options | Cost-effective and timely delivery | Cost efficiency |

Logistics Capabilities | Reliable and safe delivery | Reliability of supply |

Supplier Reputation | Years in business, certifications, customer reviews | Risk mitigation |

You should also check what other customers say. Look for positive feedback on quality and service. See how the supplier handles problems. Testimonials from long-term customers can tell you a lot about dependability.

Note: Technical compliance and certification should always come first. Certified transformers keep your system safe and reliable, which lowers your total cost of ownership in the long run.

When you look at transformer prices, don’t just focus on the sticker price. The total cost of ownership includes everything you spend over the life of the transformer. This means you need to think about installation, maintenance, energy losses, repairs, and even resale value. Sometimes, a cheaper transformer costs more in the end because it needs more repairs or uses more energy. If you choose a model with a good warranty, strong after-sales support, and high efficiency, you can save money year after year. Always add up all the costs before you make your final choice. That way, you get the best value for your investment.

When you shop for an 11kV transformer, you want to avoid the most common mistakes buyers make. These errors can lead to higher cost, wasted time, and headaches down the road. Let’s break down the top pitfalls so you can make a smarter choice.

You might think you know the total cost of your transformer, but many buyers miss hidden expenses. These can sneak up on you and make your project much more expensive than you planned.

Faster equipment deterioration means you may need to buy a new transformer sooner, which increases your overall cost.

Downtime from unexpected failures can interrupt your operations and lead to lost profits.

Labor and supplies for repairs and installations add to your cost, especially if you need emergency service.

Increased maintenance demands can drive up your ongoing cost, especially if your transformer isn’t reliable.

Safety risks from failing transformers can result in extra cost, like workers’ compensation claims or fines.

Tip: Always ask your supplier for a full breakdown of the cost, including installation, maintenance, and warranty. This helps you avoid surprises and keeps your budget on track.

You might focus only on what you need today, but forgetting about future growth can lead to much higher cost later. If your business expands or your power needs increase, a transformer that’s too small will hold you back.

Over the life of your transformer, energy dissipated as heat can cost up to five times the purchase price. If you choose a cheaper model now, you could pay much more in operational cost over the next 30 to 40 years. Planning for future capacity helps you avoid expensive upgrades and keeps your cost lower in the long run.

Note: Think about your future needs before you buy. A little extra investment now can save you a lot of cost later.

It’s easy to look for the lowest price, but that’s not the smartest way to buy a transformer. The initial price is just one part of the total cost. You need to consider everything you’ll spend over the life of the equipment.

Cost Factor | Description |

|---|---|

Initial Price | The upfront cost of purchasing the transformer. |

Operational Expenses | Costs incurred during the transformer’s lifespan, including energy losses. |

Maintenance Costs | Regular upkeep required to ensure efficient operation. |

Downtime Risk | Potential costs associated with transformer failure and downtime. |

Residual Value | The expected value of the transformer at the end of its life. |

Total Cost of Ownership (TCO) | A comprehensive view that includes all costs over 20-30 years. |

Low initial price does not guarantee low operating cost. Sometimes, a higher efficiency transformer costs more up front but saves thousands every year in energy losses. If you focus only on price, you might end up paying much more in total cost.

Callout: Always compare the total cost of ownership, not just the sticker price. This helps you make a smart investment and avoid regrets.

You’ve seen how the price for an 11kV transformer can range from $30,000 to $150,000, depending on what you need. Check out this quick table for a snapshot:

Specification | Estimated Price (USD) |

|---|---|

Standard Oil-Immersed Transformer | $30,000 – $50,000 |

High-Efficiency Copper Winding Model | $50,000 – $80,000 |

Custom-Built with Advanced Protection | $80,000 – $120,000 |

Smart Transformer with Remote Monitoring | $120,000 – $150,000 |

Don’t forget about extra cost like shipping, installation, and maintenance. The main cost factors include:

Core and winding material

Cooling system

Efficiency and energy losses

Insulation and protection

Manufacturer and country of origin

Customization and accessories

If you want to keep your cost low, look at every detail before you buy. You should use the cost guide and tips to make a smart, cost-effective choice. Reputable suppliers help you manage cost by offering tailored support and expert advice. Their technical teams work with you to meet your needs and keep your cost under control. You get reliable transformers and strong after-sales service, which protects your investment and reduces long-term cost.

Tip: Always ask for a full quote so you know the total cost up front. This helps you avoid surprises and keeps your project on budget.

You can expect to pay anywhere from $4,000 to $60,000 for an 11kV transformer. The price depends on size, type, and features. Always ask for a detailed quote.

Delivery usually takes 4 to 12 weeks. Custom designs or large orders may take longer. Ask your supplier for a timeline before you order.

Oil-immersed transformers cost less and work well outdoors. Dry-type models offer better fire safety and need less maintenance. Your choice depends on your site and safety rules.

You should budget for shipping, installation, taxes, and maintenance. Some suppliers include these in the quote, but others do not. Always check the details.

You cannot upgrade the core transformer easily. If you expect growth, choose a larger unit now. This saves you money and trouble in the future.

Look for certifications like IEC, ANSI, or UL. Ask your supplier for test reports and compliance documents. Certified transformers keep your system safe.

Most suppliers offer a 1- to 3-year warranty. Some brands provide longer coverage or extra service packages. Always read the warranty terms before you buy.

Hire a licensed electrician or a certified installer. Proper installation keeps your equipment safe and protects your warranty.