Need Full Specifications?

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

XBRELE is a specialized Power Distribution Transformers manufacturer delivering high-efficiency solutions for global grids. From hermetically sealed oil-immersed S13 units to fire-safe cast resin dry-type models, our step-down transformers are certified to IEC 60076 standards.

As a specialized Power Distribution Transformers manufacturer, XBRELE integrates advanced capabilities—including fully automatic foil winding machines and vacuum drying systems—to produce reliable medium voltage equipment consistent with IEC 60076 standards.

Our portfolio covers the full spectrum of grid requirements: from robust 10kV/11kV distribution transformers for urban networks to heavy-duty 35kV power transformers for industrial substations. We maintain precise control over core stacking and coil winding to ensure optimal electrical performance.

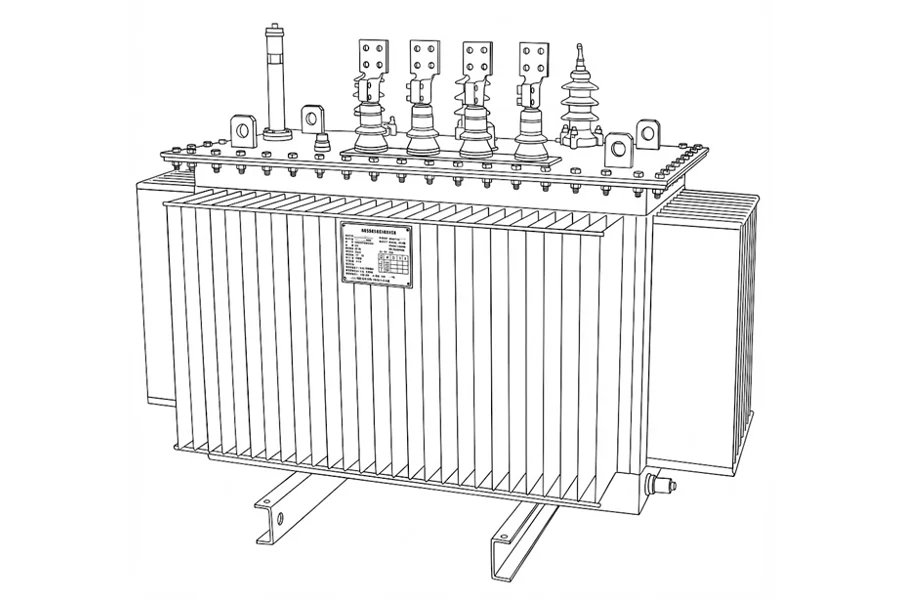

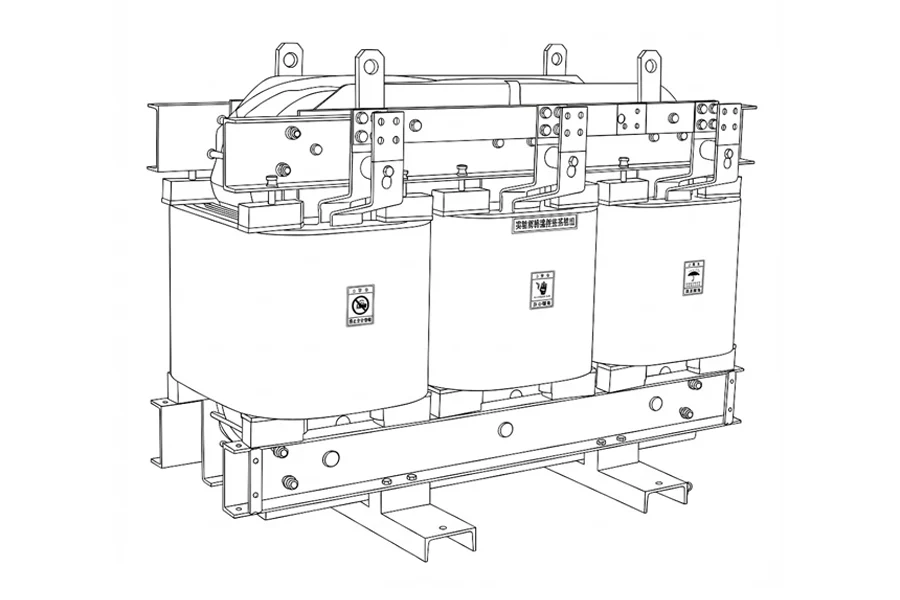

We offer two primary technologies: Oil-Immersed units with hermetically sealed corrugated tanks for outdoor durability, and Cast Resin Dry-Type units for indoor fire safety. Whether utilizing high-permeability silicon steel or advanced amorphous alloys, our focus is on reducing no-load losses and ensuring maintenance-free operation.

XBRELE supplies three distinct transformer technologies tailored for specific environments: Oil-Immersed for outdoor efficiency, Cast Resin Dry-Type for indoor safety, and Amorphous Alloy for green energy projects.

Our Oil-Immersed range includes the standard S11/S13 distribution transformers (10kV-20kV) and the heavy-duty SZ-35kV power transformers. Featuring a corrugated tank structure that eliminates the oil conservator, they are fully hermetically sealed to prevent oxygen ingress and oil aging.

Designed for high fire-safety requirements, our Dry-Type series covers standard SCB10/11/12/13 (10kV-20kV), environmental SG(B)10 (Class H), and the high-voltage SCB11-35kV power transformer.

For projects demanding maximum energy efficiency, the SBH15 (Oil) and SCBH15 (Dry) series utilize advanced amorphous alloy strip cores. This technology reduces no-load losses by approximately 75% compared to silicon steel S9 models.

XBRELE transformers are engineered for low-loss stability. We utilize high-permeability grain-oriented cold-rolled silicon steel for the core and oxygen-free copper for windings, ensuring compliance with global efficiency standards.

XBRELE transformers are engineered for resilience. From dust-heavy mining sites to strict fire-safety zones in urban centers, our equipment ensures stable power distribution in the most demanding environments.

Our hermetically sealed oil-immersed transformers (S11/S13) are specifically suited for petroleum, metallurgy, and coal industries. The corrugated tank design withstands high-dust environments common in chemical and industrial zones.

For commercial centers, high-rise buildings, and residential districts, our SCB Dry-Type series offers superior fire safety. They can be installed directly in load centers to reduce line losses and ensure safe power supply.

Providing reliable power for airports, ports, and railway transportation. Our cast resin transformers are designed to handle vibration and load fluctuations, ensuring continuous operation for critical transit infrastructure.

Supporting power plants and regional substations. Our Amorphous Alloy (SBH15) and 35kV power transformers are optimized for power generation and supply networks, minimizing transmission losses.

We control every stage of production. From our Computer-Aided Design (CAD) center to our advanced testing shielding rooms, XBRELE ensures every transformer meets the highest industry standards.

Our facility utilizes fully automatic aluminum foil winding machines and CNC silicon steel transverse cutting lines. This automation ensures consistent coil tension and core stacking precision for low-loss performance.

We employ fully automatic vacuum drying and coating devices. This process completely removes moisture and prevents air contact during assembly, guaranteeing the insulation longevity of our hermetically sealed units.

Reliability is verified. All XBRELE transformer series have passed the rigorous type tests certification of the National Transformer Quality Supervision and Inspection Center, complying with GB and IEC standards.

Trusted internationally. Our transformers are currently powering grids and industrial projects across diverse regions, with successful exports to markets including Vietnam, Malaysia, and Mongolia.

Expert answers on selecting reliable Power Distribution Transformers. Learn about our S13 Oil-Immersed, SCB Dry-Type, and 35kV power solutions for global grids.