Need Full Specifications?

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

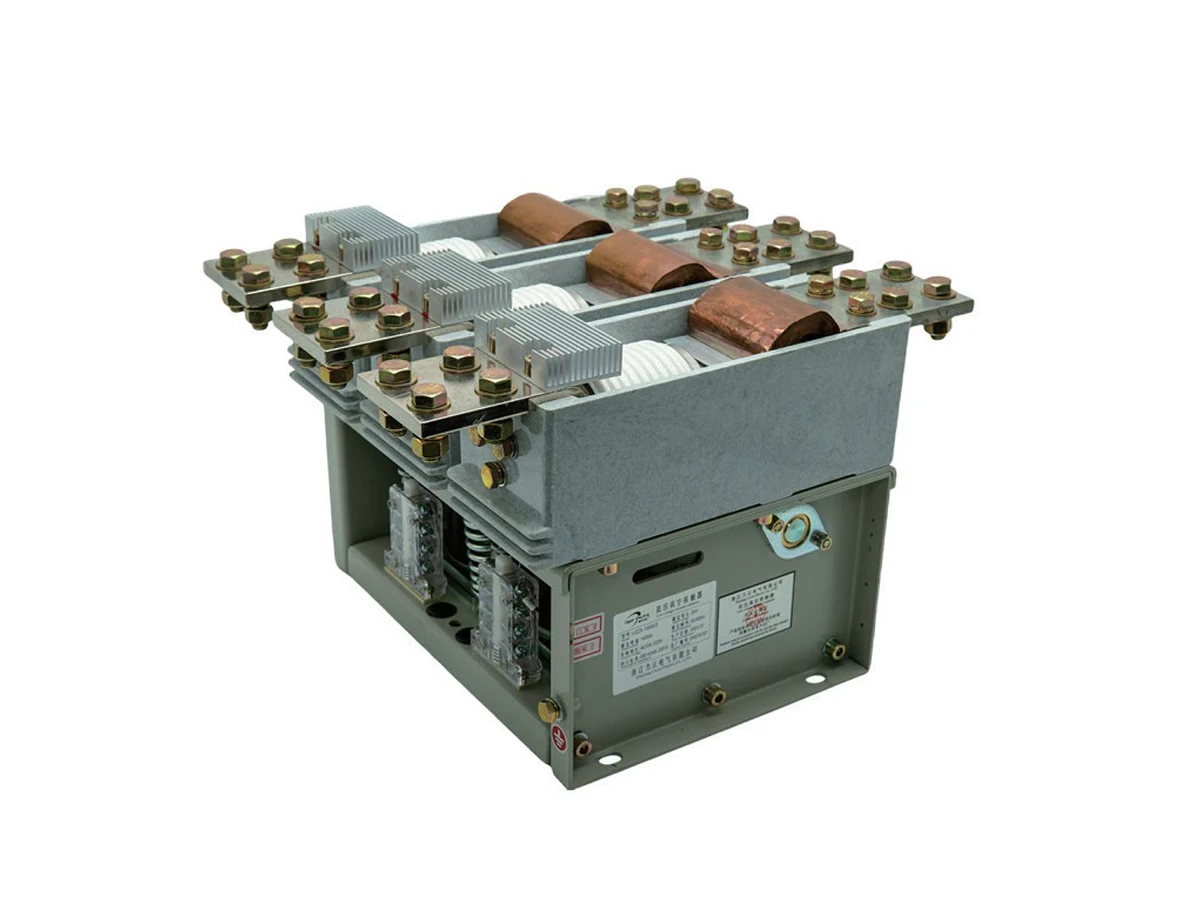

XBRELE delivers specialized switching solutions for harsh environments. Featuring the CKJ Series for 1140V mining networks (AC-4 Duty) and the LZNJ Series with solid-embedded poles for maintenance-free 12kV operation in dust and humidity.

This specialized portfolio targets applications where standard medium-voltage contactors may not fit. We offer two distinct categories to address specific industrial challenges:

1. Low Voltage Series (CKJ & LCZ3): Designed for 1.14kV (1140V) and 2kV networks common in mining and heavy industrial drives. With rated currents extending up to 3200A, these low voltage vacuum contactors are perfect for controlling large motors in soft-starter cabinets and oilfield equipment.

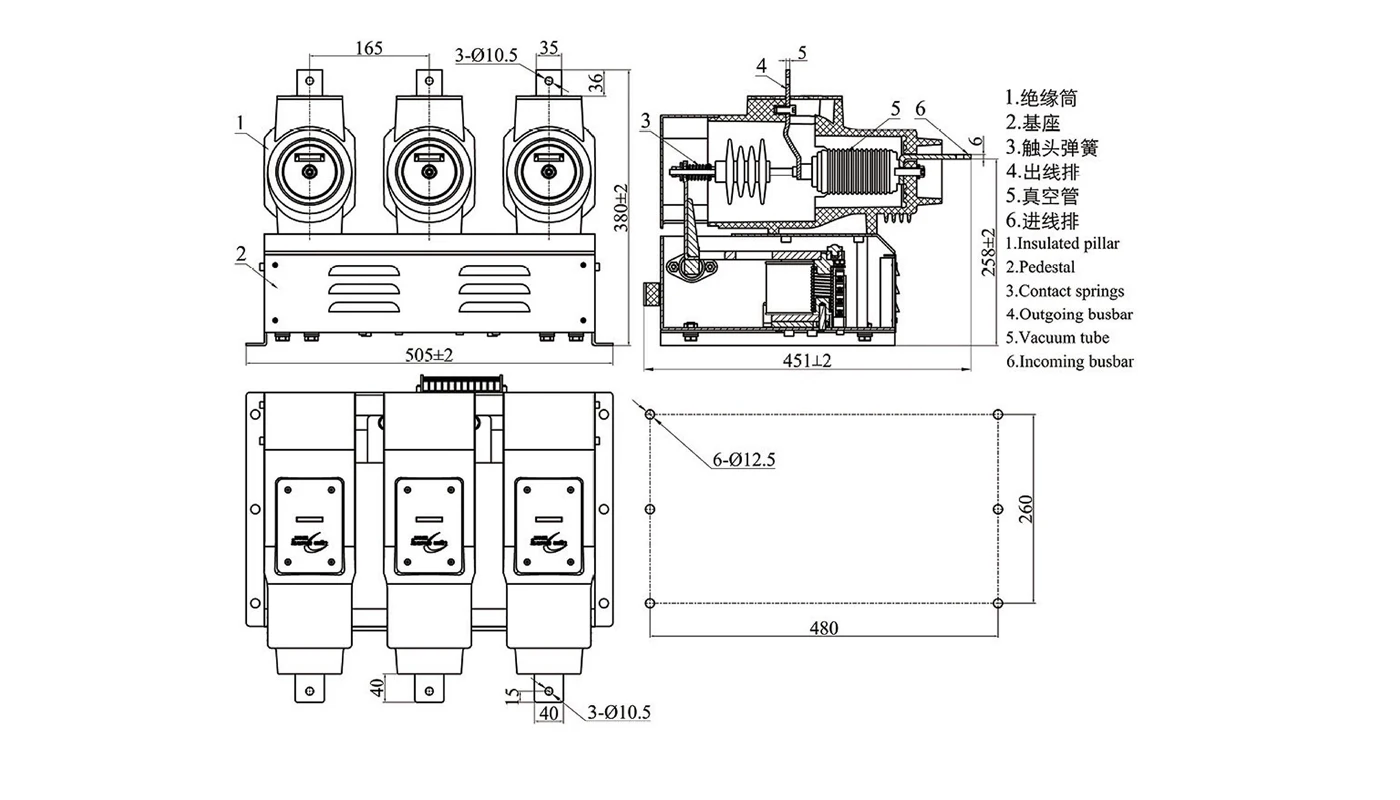

2. Solid-Insulated Series (LZNJ): A 12kV vacuum contactor featuring Solid-Embedded Poles. By encapsulating the vacuum interrupter in epoxy resin, the LZNJ series offers superior resistance to dust, moisture, and vibration, making it the ultimate choice for polluted environments like cement and steel plants.

For our complete range of switching solutions, visit the Vacuum Contactor pillar page .

Select a category below to view full technical parameters for our 1.14kV Mining, 2kV High Current, and 12kV Solid-Insulated series.

Engineered for 1140V underground mining networks. Capable of handling AC-4 duty cycles (frequent inching/plugging) common in mining machinery.

Technical Parameters: CKJ Series (1.14kV)

| No. | Item | Unit | CKJ5-1.14 | CKJ20-1.14 | CKJ1-1.14 |

|---|---|---|---|---|---|

| 1 | Rated Voltage | kV | 1.14 | 1.14 | 1.14 |

| 2 | Rated Current | A | 1000, 1250 | 630, 800 | 160 |

| 3 | Vacuum Fracture Withstand | V | 7000 | 6000 | 6000 |

| 4 | Power Freq. Withstand | V | 4200 | 4200 | 4200 |

| 5 | Rated Breaking Capacity | – | 5kA | 8Ie (25 times) | 8Ie (25 times) |

| 6 | Rated Making Capacity | – | 6.3kA | 10Ie (100 times) | 10Ie (100 times) |

| 7 | Short-time Withstand | kA | 6.3 | 6.3 (10Ie) | 1.6 (10Ie) |

| 8 | Peak Withstand | kA | 16 | 16 (25Ie) | 4 (25Ie) |

| 9 | Overload Withstand | kA | 9.45 | 9.45 | 2.4 (15Ie) |

| 10 | Short Circuit Break/Close | – | – | 10Ie (1 time) | 10Ie (1 time) |

| 11 | Rated Contact Gap | mm | 3±0.5 | 2.5±0.5 | 2±0.5 |

| 12 | Overtravel | mm | ≥1.5 | ≥1.5 | ≥1 |

| 13 | Closing Synchronism | ms | 2 | 2 | – |

| 14 | Mechanical Life | 10⁴ | 50 | 50 | 50 |

| 15 | Electrical Life (AC3 / AC4) | 10⁴ | 25 / 10 | 25 / 10 | 25 / 10 |

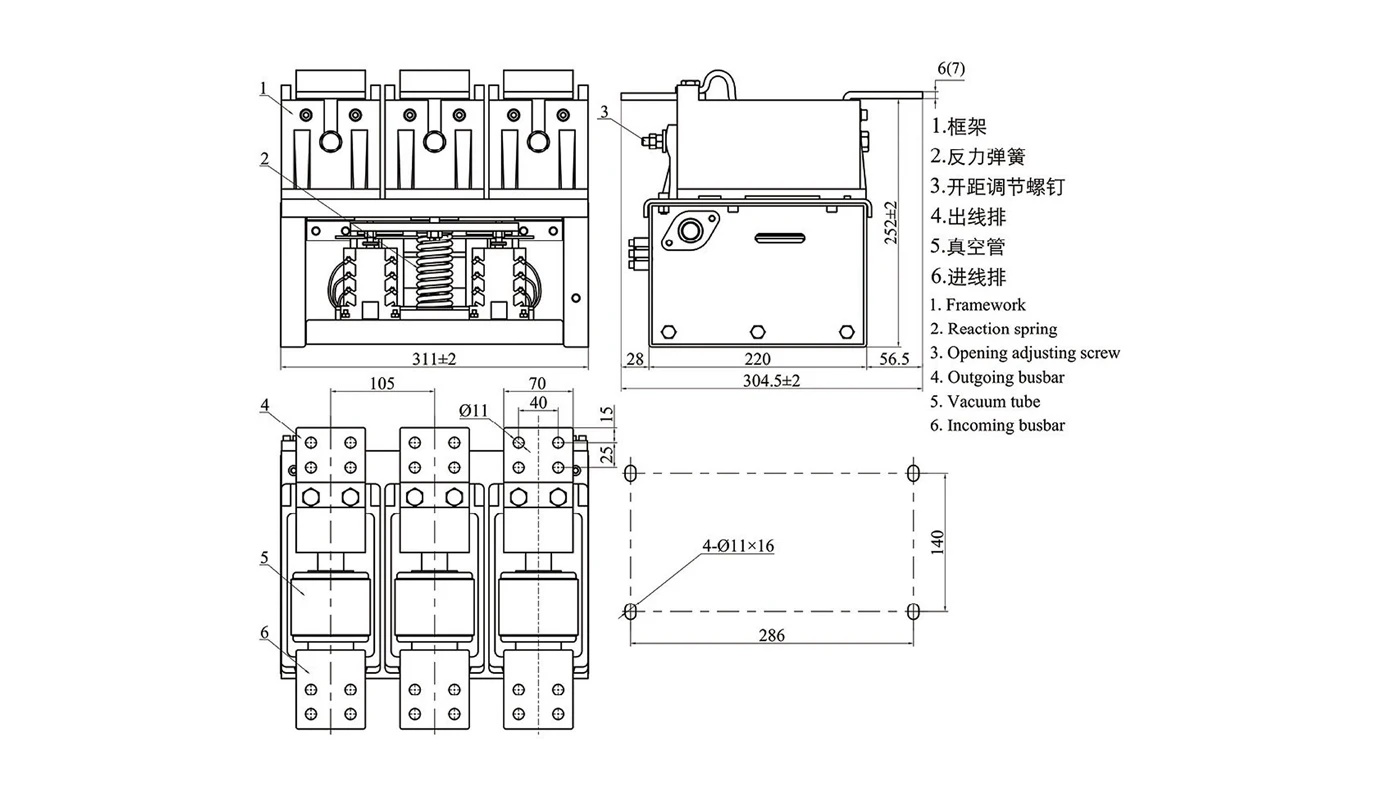

Outline Dimensions

Designed for heavy industrial drives and soft starters requiring high current capacity (up to 3200A) at voltages of 1.14kV and 2kV.

Technical Parameters: LCZ Series (High Current)

| No. | Item | Unit | LCZ3-3200 | LCZ3-2000 | LCZ1-1.14 |

|---|---|---|---|---|---|

| 1 | Rated Voltage | kV | 2 | 2 | 1.14 |

| 2 | Rated Current | A | 3200 | 1600, 2000 | 1600, 2000 |

| 3 | Vacuum Fracture Withstand | V | 10000 | 10000 | 7000 |

| 4 | Power Freq. Withstand | V | 4200 | 4200 | 4200 |

| 5 | Rated Breaking Capacity | – | 2.5Ie (AC2) | 4Ie (AC2) | 4Ie (AC2) |

| 6 | Rated Making Capacity | – | 4Ie (AC2) | 4Ie (AC2) | 4Ie (AC2) |

| 7 | Overload Withstand | kA | 10 | 10 | 10 |

| 8 | Rated Contact Gap | mm | 3.5±0.5 | 3.5±0.5 | 3.5±0.5 |

| 9 | Overtravel | mm | 2 | 2 | 2 |

| 10 | Closing Bounce | ms | 2 | 2 | 2 |

| 11 | Closing Time | ms | – | – | 60 |

| 12 | Opening Time | ms | – | – | 40 |

| 13 | Mechanical Life | 10⁴ | 50 | 50 | 50 |

| 14 | Electrical Life (AC2) | 10⁴ | 25 | 25 | 25 |

Outline Dimensions (LCZ LV Series)

The LZNJ series features a maintenance-free solid insulation structure. Vacuum interrupter is embedded in epoxy resin for superior protection.

Technical Parameters: LZNJ Series

| No. | Item | Unit | LZNJ-12/630 |

|---|---|---|---|

| 1 | Rated Voltage | kV | 12 |

| 2 | Rated Current | A | 630 |

| 3 | Power Freq. Withstand | kV | 42 |

| 4 | Lightning Impulse | kV | 75 |

| 5 | Rated Breaking Capacity | A | 8Ie (25 times) |

| 6 | Rated Closing Capacity | A | 10Ie (100 times) |

| 7 | Short-time Withstand | kA | 6.3 (10Ie) |

| 8 | Peak Withstand | kA | 16 (25Ie) |

| 9 | Peak Current Time | s | 2 |

| 10 | Rated Contact Gap | mm | 5.5±0.5 |

| 11 | Overtravel | mm | 1.5 |

| 12 | Main Circuit Resistance | μΩ | ≤80 |

| 13 | Closing/Opening Time | ms | ≤60 / ≤40 |

| 14 | Mechanical Life | 10⁴ | 30 (300,000) |

| 15 | Electrical Life (AC3 / AC4) | 10⁴ | 25 / 10 |

Outline Dimensions

From the dusty depths of mines to humid industrial plants, XBRELE’s specialized contactors are built to endure conditions where standard equipment fails.

The LZNJ series uses epoxy resin to completely encapsulate the vacuum interrupter, isolating it from the external environment.

Specifically rated for 1140V networks, bridging the gap between standard LV (690V) and MV (3.3kV) for underground equipment.

For massive industrial motors and drives, we offer specialized solutions handling up to 3200A at 2kV voltage levels.

Whether it’s the casting quality of our solid poles or the durability of our heavy-duty contactors, XBRELE ensures zero compromise through specialized manufacturing checks.

Our manufacturing line is adapted to handle both the precision casting required for solid insulated poles and the heavy-duty assembly required for demanding industrial and mining contactor applications.

For solid-insulated designs, we use Automatic Pressure Gelation (APG) epoxy casting to mould the pole. This ensures a void-free structure with high dielectric strength and tracking resistance.

Low-voltage contactors undergo rigorous AC-3 and AC-4 duty testing to simulate frequent inching, plugging and heavy starting conditions under high arc stress.

Each vacuum interrupter is checked for contact resistance in the micro-ohm range and undergoes vacuum integrity testing before assembly to guarantee arc-extinguishing performance.

We precisely adjust overtravel and contact pressure to keep bounce within limits and prevent contact welding in the event of short-circuit or overload conditions.

Finished units are subjected to power-frequency withstand tests in line with product standards, ensuring safety margins between main circuit, control circuit and ground.

Our testing protocols comply with IEC and GB standards for both low-voltage switchgear and solid-insulated components, ensuring reproducible performance from batch to batch.

Detailed test reports and type test certificates can be provided on request for project documentation and third-party verification.

Whether you need urgent replacements for a mining site or batch delivery for a new plant, XBRELE ensures your low voltage and solid-insulated contactors arrive on time and ready to install.

Our manufacturing lines are optimized for quick turnaround of standard industrial models.

Industrial shipping requires robust packaging. We ensure your equipment withstands long-distance transport.

Our technical team helps you integrate these specialized contactors into your control panels.

Engineering insights on selecting the right low voltage vacuum contactor for mining (1.14kV) or solid-insulated models for harsh industrial environments.