Need Full Specifications?

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

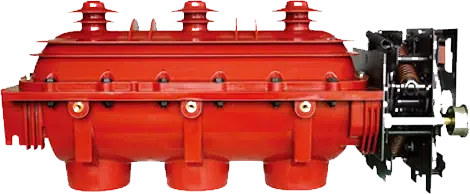

XBRELE manufactures precision-engineered Switchgear Parts for 12kV-40.5kV power systems. We supply the critical insulation backbone for KYN28, XGN, and GIS panels, ensuring seamless integration and IEC compliance.

Featuring advanced APG Technology and strict X-Ray Flaw Detection, our components deliver superior dielectric strength and zero partial discharge reliability.

XBRELE supplies the critical “passive ecosystem” for Medium Voltage power distribution. From the insulation backbone to the conductive core, our components are precision-molded to withstand the rigors of 12kV–40.5kV networks.

Quality starts with material science. We utilize international advanced APG (Automatic Pressure Gelation) technology for all Epoxy Contact Boxes and bushings, ensuring bubble-free insulation with superior dielectric strength. Every batch undergoes rigorous X-Ray flaw detection and Partial Discharge (PD) testing to guarantee zero internal defects.

Our mechanical portfolio is equally robust. Designed to integrate seamlessly with Vacuum Circuit Breakers, our high-purity T2 Copper Contacts feature thick silver plating for minimal resistance. Additionally, our snap-action JN15 Earthing Switches provide reliable safety grounding, fully compliant with IEC 60694 standards.

Browse our complete inventory of OEM parts for KYN28, XGN, and GIS switchgear panels. Fully IEC certified.

CH3 series spouts for KYN28 panels. APG epoxy resin insulation, 12kV to 40.5kV, rated for 630A–4000A.

TG3 through-wall insulators for busbar isolation. Available in rectangular (Air) and cone (Gas) types.

High-strength epoxy post insulators (ZJ) and capacitive voltage sensors (CG5) for live-line indication.

Indoor HV earthing switches for safety grounding. JN15 (12/24kV) and JN22 (40.5kV) with snap-action.

Silver-plated Tulip Contacts, T2 Copper Arms, and insulating rods for VS1/ZN85 vacuum circuit breakers.

FLN36-12 indoor HV SF6 load break switches and surge arresters for Ring Main Units (RMU).

Essential cabinet accessories: Electromagnetic locks (DSN), heaters, and voltage indicators (DXN).

As a dedicated manufacturer, XBRELE produces precision-engineered MV Switchgear Components designed to exceed IEC 60694 requirements. By combining high-purity materials with advanced APG molding, we deliver parts that ensure the long-term safety and stability of KYN28 and GIS distribution panels.

From air-insulated KYN28 panels to gas-insulated RMUs, XBRELE supplies the essential insulation and mechanical backbone. Our parts are dimensionally compatible with ABB, Siemens, and Schneider equivalent switchgear designs.

The primary application for our CH3 Contact Boxes and TG3 Wall Bushings. We provide the complete insulation kit for 12kV/24kV withdrawable switchgear, ensuring perfect alignment for VCB handcarts.

Specialized components for gas-insulated switchgear. Including FLN36 Load Break Switches, gas-tight bushings, and cable accessories designed for compact, sealed SF6 environments.

Essential safety mechanisms for power distribution stations. Our JN15 Earthing Switches and DXN Voltage Indicators provide critical protection for maintenance personnel during outages.

High-purity Tulip Contacts and Copper Arms for upgrading or repairing existing circuit breakers. We offer custom dimensions to replace legacy components in aging switchgear.

XBRELE is not just a parts supplier; we are an OEM partner. From raw material selection to final testing, we control every step to ensure your KYN28 and GIS switchgear meets global reliability standards.

We utilize international advanced epoxy resin automatic pressure gelation (APG) machines. This ensures bubble-free insulation, high mechanical strength, and zero partial discharge for all contact boxes and bushings.

Quality is verified, not assumed. Our facility is equipped with X-Ray flaw detectors, shielding partial discharge test rooms, and high-low temperature test units to guarantee defect-free delivery.

We use only high-purity T2 Copper for conductive arms and tulip contacts, enhanced with thick silver plating. This minimizes contact resistance and ensures stable temperature rise performance under load.

Simplify your supply chain. We provide the complete passive ecosystem for switchgear assembly—from insulation (insulators, spouts) to mechanisms (earthing switches, locks)—all from a single ISO-certified source.

Expert answers regarding insulation, earthing, and assembly for KYN28 & GIS panels.