Need Full Specifications?

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

XBRELE LCZ Series offers robust high voltage vacuum contactors engineered for the toughest environments. From 12kV Plateau models (3500m altitude) to 40.5kV ultra-high voltage units, we provide reliable single-pole switching solutions for mining and heavy industry.

The XBRELE LCZ series is designed to meet the specialized needs of industrial power systems requiring a high voltage vacuum contactor beyond the standard 12kV range. With ratings extending to 40.5kV and specialized single-pole enclosed structures, this series ensures safety and reliability where ordinary contactors fail.

12kV & 15kV Plateau Models (GF): Specifically engineered for high-altitude regions. Verified for installation at altitudes up to 3500 meters, they feature reinforced insulation to prevent flashover in thin air environments like mountain mines.

24kV & 40.5kV Ultra-High Voltage Models: For demanding feeder automation, the LCZ7-40.5F offers powerful breaking capacity. These high voltage vacuum contactors feature extended creepage distances (Impulse withstand up to 185kV), making them ideal for wind farms and heavy industrial grids.

For a broader view of XBRELE’s full switching portfolio, including standard medium-voltage solutions, please visit the Vacuum Contactor pillar page .

Detailed parameters for our single-pole series. Select a voltage range to view specifications for 12kV, 24kV, and 40.5kV models, designed for high-voltage switchgear integration.

This group features the LCZ1 and LCZ7 series designed for 12kV and 15kV applications. A key highlight is the inclusion of “GF” (Plateau) models, which are engineered to withstand the challenging insulation requirements of high-altitude environments up to 3500 meters.

These contactors feature a single-pole enclosed design, making them highly adaptable for custom switchgear in mining, traction power, and industrial control.

Please refer to the table below for the complete list of 15 technical parameters.

Technical Parameters: 12kV / 15kV Models

| No. | Item | Unit | LCZ1-12F | LCZ1-12GF | LCZ7-12GF | LCZ7-15F |

|---|---|---|---|---|---|---|

| 1 | Rated voltage | kV | 12 | 12 | 12 | 15 |

| 2 | Rated current | A | 160-630 | 160-630 | 160-630 | 160-630 |

| 3 | Power freq. withstand | kV | 42 | 42 | 42 | 50 |

| 4 | Lightning impulse | kV | 75 | 75 | 75 | 88 |

| 5 | Rated breaking capacity | A | 8Ie | 8Ie | 8Ie | 8Ie |

| 6 | Rated closing capacity | A | 10Ie | 10Ie | 10Ie | 10Ie |

| 7 | Short-time withstand | kA | 10Ie | 10Ie | 10Ie | 10Ie |

| 8 | Peak withstand | kA | 25Ie | 25Ie | 25Ie | 25Ie |

| 9 | Overload withstand | kA | 15Ie | 15Ie | 15Ie | 15Ie |

| 10 | Short circuit break/close | A | 10Ie | 10Ie | 10Ie | 10Ie |

| 11 | Rated contact gap | mm | 5.5±0.5 | 6±0.5 | 6±0.5 | 6±0.5 |

| 12 | Overtravel | mm | 1.5 | 1.5 | 1.5 | 1.5 |

| 13 | Main circuit resistance | μΩ | – | – | ≤100 | ≤100 |

| 14 | Mechanical life | 10⁴ | 50 | 50 | 50 | 50 |

| 15 | Electrical life (AC3) | 10⁴ | 25 | 25 | 25 | 25 |

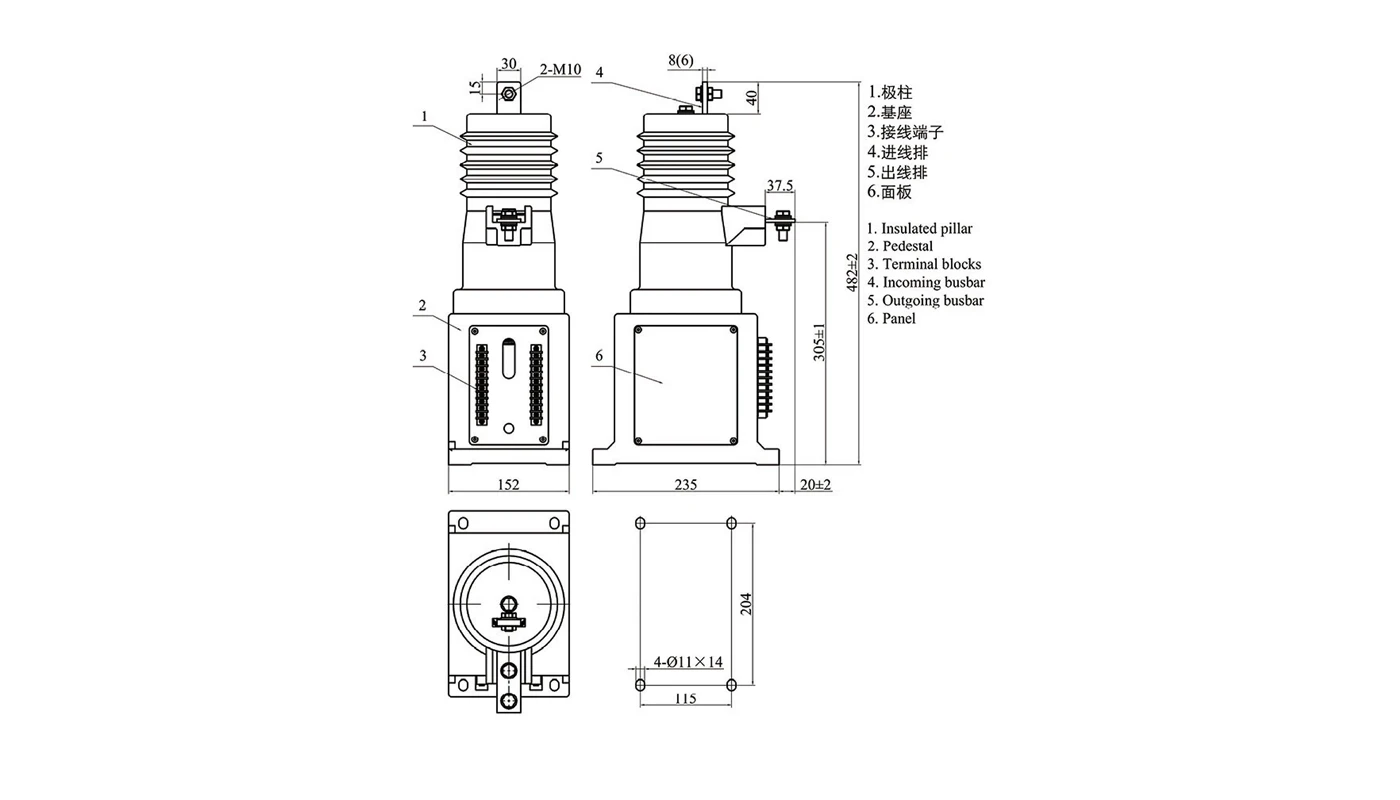

Outline & Mounting Dimensions

For applications surpassing standard MV ratings, the LCZ series offers reliable high voltage vacuum contactors at 24kV and 40.5kV. The LCZ1 and LCZ7 series in this class feature elongated insulation paths to handle extreme impulse voltages.

The table below provides the complete set of 15 technical specifications for these ultra-high voltage units.

Technical Parameters: 24kV / 40.5kV Models

| No. | Item | Unit | LCZ7-24F | LCZ1-40.5F | LCZ7-40.5F |

|---|---|---|---|---|---|

| 1 | Rated voltage | kV | 24 | 40.5 | 40.5 |

| 2 | Rated current | A | 630, 800 | 630-1250 | 630-1250 |

| 3 | Power freq. withstand | kV | 65 | 95 | 95 |

| 4 | Lightning impulse | kV | 125 | 185 | 185 |

| 5 | Rated breaking capacity | A | 8Ie | 8Ie | 8Ie |

| 6 | Rated closing capacity | A | 10Ie | 10Ie | 10Ie |

| 7 | Rated short-time current | kA | 10Ie | 10 | 10 |

| 8 | Rated peak withstand | kA | 25Ie | 25Ie | 16 |

| 9 | Overload withstand | kA | 15Ie | 10 | 10 |

| 10 | Short circuit break/close | A | 10Ie | 10Ie | 10Ie |

| 11 | Rated contact gap | mm | 9±1 | 17±1 | 17±1 |

| 12 | Overtravel | mm | ≥2 | ≥3 | ≥3 |

| 13 | Main circuit resistance | μΩ | ≤100 | – | ≤100 |

| 14 | Mechanical life | 10⁴ | 20 | 10 | 10 |

| 15 | Electrical life (AC3) | 10⁴ | 10 | 2 | 2 |

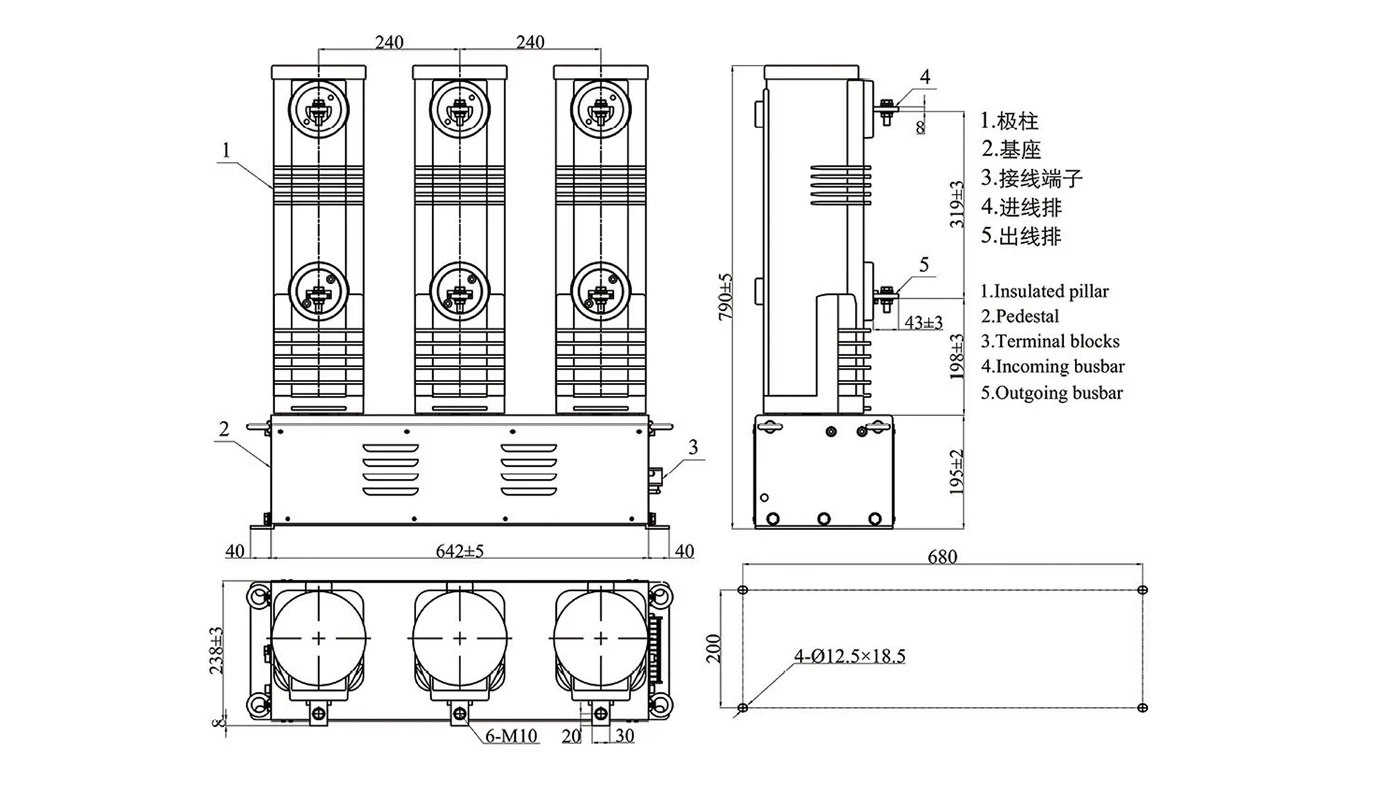

Outline & Mounting Dimensions

The LCZ series goes beyond standard limits. With specialized designs for plateau environments and ultra-high voltages, XBRELE ensures reliable high voltage vacuum contactor performance where others fail.

The ‘GF’ (Plateau Type) models are specifically designed to overcome the thin air and insulation challenges of high-altitude regions.

Covering a voltage spectrum far beyond standard MV contactors, the LCZ series offers reliable control up to 40.5kV.

The unipolar construction allows for maximum flexibility in switchgear design, especially for custom or restricted spaces.

The LCZ series demands rigorous manufacturing standards. From reinforcing insulation for 3500m altitude to tuning mechanical drives for 40.5kV interrupters, we ensure every single-pole unit is field-ready.

XBRELE’s dedicated high-voltage line ensures the LCZ series meets the unique dielectric and mechanical requirements of unipolar switchgear.

For GF models, we verify the integrity of the enclosed pole structure or reinforced insulators to guarantee creepage distances suitable for thin air at 3500m.

Precise alignment of the 24kV/40.5kV vacuum tubes is critical. We use laser-guided fixtures to ensure concentricity, preventing lateral stress on the bellows.

Contact gaps (6mm – 17mm) and overtravel (≥1.5mm – 3mm) are individually calibrated to match the specific voltage rating of each LCZ model.

Whether utilizing standard coils or permanent magnets, the drive force is adjusted to ensure consistent closing speeds and minimal bounce (<2ms or <3ms).

Every unit undergoes a rigorous power-frequency withstand test (up to 95kV for 40.5kV models) to validate insulation before packing.

Beyond standard IEC tests, the LCZ series undergoes specialized verification for impulse voltage and high-altitude performance.

Dielectric test reports provided with every shipment.

Custom FAT available for critical mining projects.

Shipping sensitive high-voltage equipment requires precision. XBRELE provides specialized packaging and engineering support to ensure your LCZ series contactors are ready for installation, from sea level to 3500m.

We optimize our manufacturing for both standard single-pole orders and custom high-voltage configurations.

LCZ units feature extended insulation structures that require careful handling during transit.

Our team helps you integrate single-pole units into complex switchgear or high-altitude environments.

Engineering insights on selecting LCZ high voltage vacuum contactors for 40.5kV systems, high-altitude mining projects, and specialized industrial switchgear.