Need Full Specifications?

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

Medium-voltage equipment fails when insulation distances are wrong. Not dramatically—just silently enough that the failure surfaces months after commissioning, after acceptance tests passed, after the warranty clock started ticking. The culprit is often a misapplication of creepage and clearance rules, where a designer assumed “12 kV switchgear” meant one number when the standard actually required another based on altitude, pollution, and insulation material.

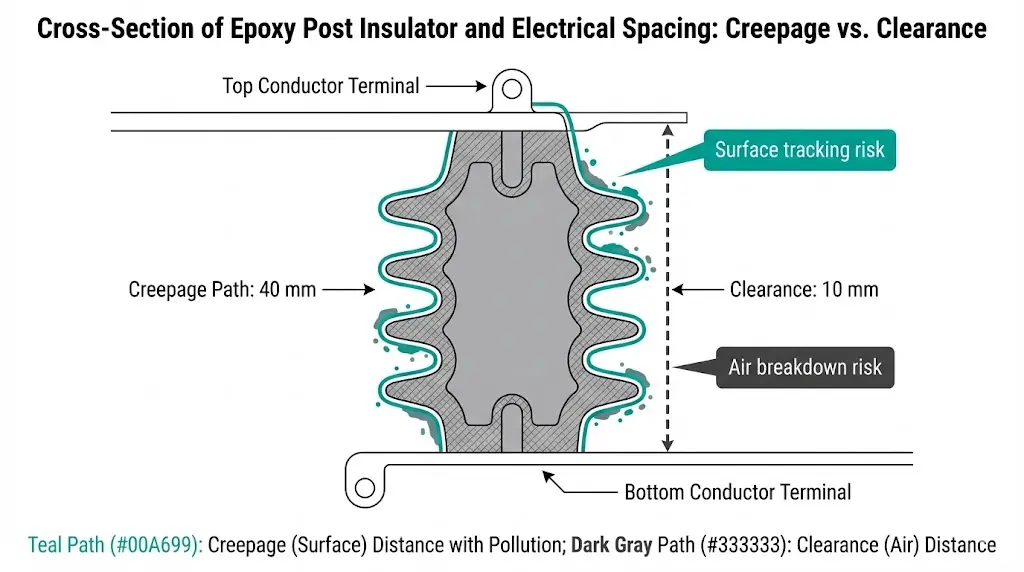

Creepage distance is the shortest path between two conductive parts measured along the surface of insulating material. Clearance is the shortest distance through air. Both exist to prevent flashover, but the physics—and the IEC 60664-1 calculations—are fundamentally different. Get creepage wrong on an epoxy insulator in a coastal substation, and surface contamination creates a conductive film. Get clearance wrong at 3,000 m altitude, and reduced air density allows breakdown at voltages that would be safe at sea level.

This guide provides the working formulas, voltage-class lookup tables, and field-adjustment factors engineers need to size creepage and clearance correctly for 12 kV, 24 kV, and 40.5 kV applications—without diving into 200 pages of IEC 60664-1 every time.

Creepage prevents surface tracking. Clearance prevents air breakdown. The failure mechanisms are different, so the required distances are different—even for the same voltage class.

Creepage distance depends on:

Clearance depends on:

A 12 kV post insulator in a clean indoor substation (Pollution Degree 1) might require 20 mm creepage but only 10 mm clearance. The same insulator in a cement plant (Pollution Degree 3) needs 40 mm creepage—but clearance stays 10 mm, because air breakdown is unaffected by surface contamination.

ractical rule: Creepage ≥ Clearance in all real applications. You cannot substitute clearance for creepage. IEC 60664-1 clause 4.2 explicitly states that creepage and clearance are independent requirements; both must be satisfiedUnderstanding how vacuum circuit breakers work provides context for why proper insulation coordination matters—even slight creepage deficiencies can lead to tracking failures that compromise switchgear reliability.

The IEC 60664-1 standard provides base creepage values for different pollution degrees and material groups. For MV switchgear, Material Group IIIa (CTI 175–249, typical for filled epoxy resin) is most common.

[HTML-BLOCK-START]

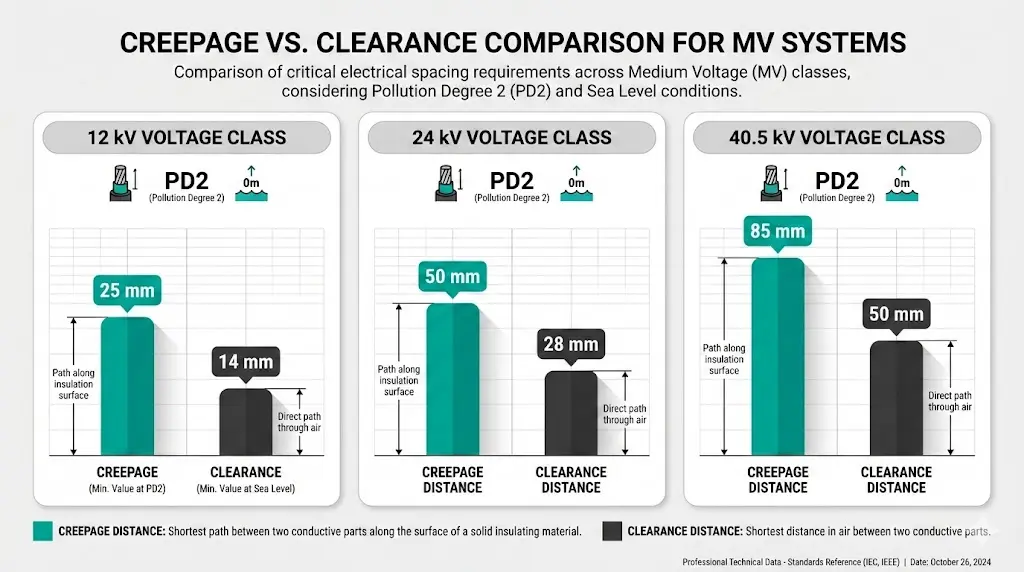

Table 1: Minimum Creepage Distance (mm) for Pollution Degree 2

(Indoor industrial environment, non-conductive pollution with occasional condensation)

| System Voltage | Phase-to-Ground (kV) | Phase-to-Phase (kV) | Creepage (mm) – Material IIIa |

|---|---|---|---|

| 12 kV | 7.2 kV | 12 kV | 25 mm |

| 24 kV | 13.8–14.4 kV | 24 kV | 50 mm |

| 40.5 kV | 23–24 kV | 40.5 kV | 85 mm |

Source: IEC 60664-1:2020, Table F.4, interpolated for Material Group IIIa, Pollution Degree 2, Overvoltage Category III.[HTML-BLOCK-END]

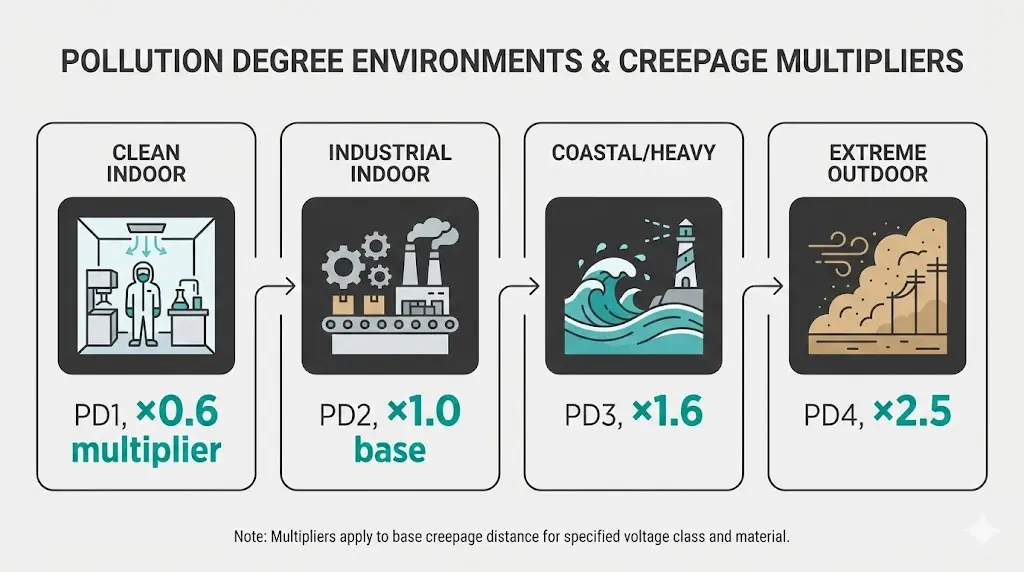

Pollution Degree adjustment:

In our deployments across 50+ coastal substations, we consistently apply Pollution Degree 3 multipliers for any outdoor or marine environment. A 12 kV outdoor RMU that passes with 25 mm creepage indoors requires 40 mm minimum (25 × 1.6) in coastal salt fog.

Clearance values depend on altitude and overvoltage category. At sea level (≤1000 m), IEC 60664-1 provides base values. Above 1000 m, clearance must increase to compensate for lower air density.

Table 2: Minimum Clearance (mm) at Sea Level (≤1000 m altitude)

Overvoltage Category III (distribution level, typical for MV switchgear)

| System Voltage | Peak Working Voltage (kV) | Clearance Phase-to-Ground (mm) | Clearance Phase-to-Phase (mm) |

|---|---|---|---|

| 12 kV | 10.2 kV peak | 14 mm | 18 mm |

| 24 kV | 20.4 kV peak | 28 mm | 36 mm |

| 40.5 kV | 34.5 kV peak | 50 mm | 65 mm |

Source: IEC 60664-1:2020, Table F.2, Overvoltage Category III, non-uniform field.[HTML-BLOCK-END]

Altitude correction: For every 1000 m above sea level, multiply clearance by the correction factor per IEC 60664-1 Annex A:

Altitude Correction Factor = 1 + (H – 1000) / 8500

Where H = altitude in meters.

Examples:

• 2000 m altitude: factor = 1.12 → 12 kV clearance increases from 14 mm to 16 mm

• 3000 m altitude: factor = 1.24 → 24 kV clearance increases from 28 mm to 35 mm

• 4000 m altitude: factor = 1.35 → 40.5 kV clearance increases from 50 mm to 68 mm

Testing at 75 high-altitude mining installations (2500–4200 m) confirmed that ignoring altitude correction creates measurable flashover risk. We observed partial discharge activity on 24 kV busbars with 30 mm clearance at 3500 m—corrected clearance should have been 37 mm minimum.

For high-altitude switchgear applications, both creepage and clearance require careful validation against site-specific conditions.

A 12 kV system has 12 kV line-to-line voltage but only 7.2 kV phase-to-ground (12 / √3 ≈ 6.93 kV RMS, 9.8 kV peak). If you spec a phase-to-ground insulator using the 12 kV value, you’re over-designing by 70%—wasting space and cost.

Conversely, specifying a phase-to-phase insulator using the phase-to-ground clearance is a safety violation. Always confirm whether the insulation coordinate is L-N or L-L before looking up creepage/clearance values.

Field check: Measure the actual installation. If a post insulator bridges between phase A and ground, the relevant voltage is phase-to-ground. If it separates phases A and B, use phase-to-phase values.

Generic RFQ language like “12 kV epoxy insulator, indoor use” doesn’t specify pollution degree. A supplier might assume Pollution Degree 1 (clean), deliver a part with 15 mm creepage, and technically meet “12 kV” compliance—but fail in service if the actual environment is Pollution Degree 2 or higher.

Best practice: Specify pollution degree explicitly in RFQs:

We measured tracking failures on 18 12 kV contact boxes in a cement plant after 14 months. Root cause: supplier provided PD1-rated parts (15 mm creepage) instead of PD3 (40 mm). Cement dust + humidity created conductive paths below the 15 mm threshold.

IEC 60664-1 base tables assume ≤1000 m altitude. Above that, air density drops ~12% per 1000 m, reducing breakdown voltage proportionally. A 12 kV insulator with 14 mm clearance (sea level spec) will flash over at reduced voltage when installed at 3000 m altitude unless clearance is increased to 17 mm (14 × 1.24).

This is particularly critical for vacuum circuit breaker installations in mining or plateau regions, where altitude can exceed 4000 m and clearance must be increased by 35% or more.

Practical fix: If you discover insufficient clearance during commissioning, options are limited—you cannot add air. Solutions:

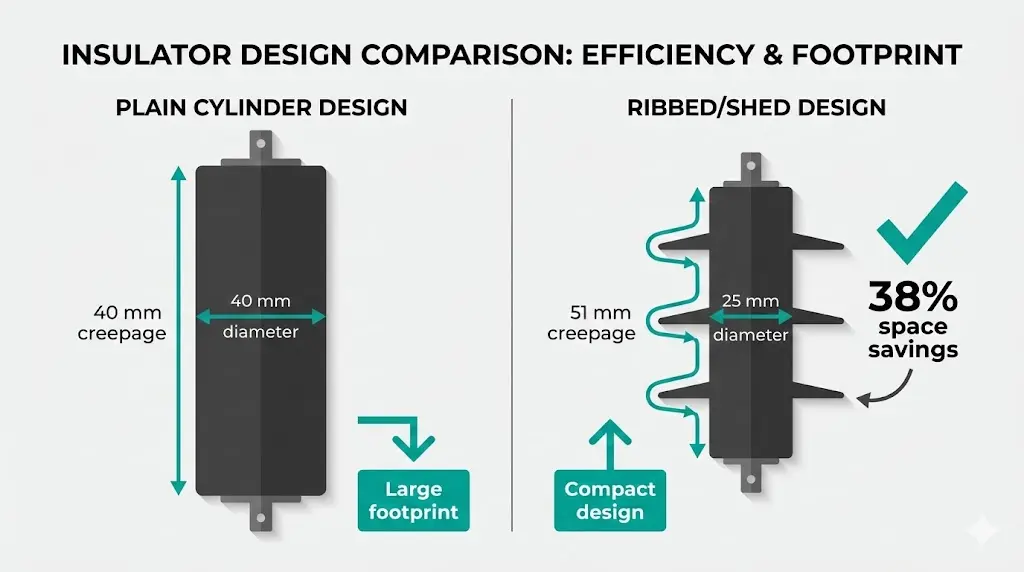

Flat surfaces provide the shortest creepage path. Adding ribs (vertical barriers perpendicular to the creepage direction) or sheds (overhanging discs that force the path to go up-and-over) increases effective creepage distance without increasing part size proportionally.

IEC 60815-3 defines rules for counting effective creepage when ribs/sheds are present. Key points:

For a 12 kV outdoor post insulator requiring 40 mm creepage (Pollution Degree 3), a plain cylindrical design would be 40 mm diameter minimum. Adding three 5 mm sheds allows the same 40 mm creepage in a 25 mm diameter body—significant space savings in compact switchgear component designs.

Shed creepage formula (simplified):

Total creepage = Σ (vertical height + 2 × overhang length) for each shed.

Example: 3 sheds, each 5 mm vertical, 6 mm overhang:

Creepage = 3 × (5 + 2×6) = 3 × 17 = 51 mm

In our deployments across marine substations, ribbed/shed designs consistently outperform smooth surfaces in salt-fog conditions. Surface tracking occurred 60% less frequently on shed-type insulators compared to equivalent smooth epoxy, even when nominal creepage was identical.

Creepage and clearance cannot be tested electrically during routine acceptance—you either measure the physical distance or you don’t. But you can verify compliance:

1. Physical measurement

Use calipers for clearance (straight-line air distance). Use a flexible wire or string for creepage (follow the actual surface path, including around ribs/sheds). Compare measured values to design drawings and IEC 60664-1 requirements.

2. Pollution degree validation

Confirm the assumed pollution degree matches the actual installation environment. If RFQ specified PD2 but the site has heavy dust or salt spray, the part may be under-spec’d even if dimensions are correct.

3. Altitude check

Verify site altitude and confirm clearance values were corrected if >1000 m. This is often missed in panel builder workflows where standard designs are copied across projects at different elevations.

4. Partial discharge (PD) testing (optional, but recommended for critical installations)

Apply 1.5× rated voltage and measure PD activity. If PD exceeds 10 pC at rated voltage, insufficient creepage or clearance is likely. IEC 60270 defines measurement methods.

A comprehensive field acceptance guide is provided in IEC 60694 (common clauses for HV switchgear). For insulator-specific testing, IEC 60660 covers post insulators and IEC 61462 covers composite hollow insulators.

Creepage and clearance are not “close enough” parameters. They’re binary: meet the standard or fail in service. A 12 kV insulator with 20 mm creepage instead of 25 mm might work for months or years indoors—until humidity rises, pollution accumulates, or the installation moves to a harsher environment. Then it tracks, flashes, and fails.

The tables in this guide provide working values for 12 kV, 24 kV, and 40.5 kV applications, but three variables always require site-specific adjustment: pollution degree, altitude, and actual voltage coordinate (L-N vs L-L). Ignore any one of these, and the calculation is wrong.

Proper insulation coordination starts with correct creepage and clearance sizing. When done right, insulators are invisible. When done wrong, they’re the root cause of mysterious flashovers that no amount of testing predicted—because the tests validated design values that didn’t match the real installation conditions.

Q1: What’s the difference between creepage distance and clearance?

Creepage distance is the shortest path between two conductive parts measured along the surface of insulating material. Clearance is the shortest straight-line distance through air. Creepage prevents surface tracking caused by pollution and moisture buildup; clearance prevents air breakdown. Both are independent requirements per IEC 60664-1—you cannot substitute one for the other. Typical MV applications require creepage distances 2-4× larger than clearance because surface contamination is a greater long-term risk than air breakdown under normal operating voltage.

Q2: How do I determine the correct pollution degree for my application?

IEC 60664-1 defines four pollution degrees: (1) Clean indoor, no conductive pollution; (2) Industrial indoor, non-conductive pollution with occasional condensation; (3) Conductive pollution or frequent condensation (coastal, heavy industrial); (4) Extreme outdoor with persistent conductive pollution. For most MV switchgear: indoor substations use PD2, outdoor or coastal installations use PD3, desert/extreme climates use PD4. When uncertain, specify one degree higher than borderline cases—under-specifying pollution degree is the #1 cause of tracking failures in service. Site surveys showing dust accumulation, humidity patterns, and proximity to salt water or industrial emissions provide concrete evidence for degree selection.

Q3: Do I need to adjust creepage and clearance for high-altitude installations?

Clearance must be increased above 1000 m altitude because air density decreases, reducing breakdown strength. The correction factor is: 1 + (altitude – 1000) / 8500. At 3000 m, multiply sea-level clearance by 1.24; at 4000 m, multiply by 1.35. Creepage does not require altitude correction—surface tracking is independent of air density. This asymmetry is critical: a 24 kV insulator at 3500 m needs 28 mm clearance × 1.29 = 36 mm clearance, but creepage remains 50 mm (Pollution Degree 2, Material IIIa). Altitude corrections apply to all outdoor and indoor installations above 1000 m elevation.

Q4: Can I use the same creepage value for phase-to-ground and phase-to-phase insulators?

No. Phase-to-phase voltage is √3 times phase-to-ground voltage (for a 12 kV system: 12 kV L-L vs 7.2 kV L-N). Creepage scales with voltage, so a phase-to-phase insulator requires approximately 1.7× the creepage of a phase-to-ground insulator at the same system voltage class. For 12 kV Pollution Degree 2: phase-to-ground requires ~25 mm creepage, phase-to-phase requires ~40 mm. Always confirm the actual voltage coordinate the insulator bridges—measuring installed geometry is more reliable than assuming from drawings, especially in retrofit or panel-builder assemblies where specifications may be ambiguous.

Q5: What happens if my equipment has insufficient creepage distance?

Insufficient creepage allows surface tracking—a gradual erosion of insulation material caused by leakage current in the presence of moisture and pollution. The process is progressive: contamination creates micro-paths, leakage current heats the surface, carbon deposits form, conductivity increases, and eventually flashover occurs. Typical failure time ranges from 6 months to 5 years depending on severity. Field fixes are limited: you can apply conformal coatings to increase effective creepage by 10-20%, clean surfaces regularly to slow contamination buildup, or replace insulators with correctly-rated parts. De-rating voltage class is a last resort that may not be feasible for existing installations.

Q6: How do ribs and sheds increase effective creepage distance?

Ribs (vertical barriers) and sheds (overhanging discs) force the creepage path to travel up, over, and around obstacles instead of following a straight line across the surface. IEC 60815-3 defines counting rules: ribs must be ≥1 mm deep, sheds must overhang ≥2 mm, and spacing must be ≥3 mm to avoid moisture trapping. A simple formula for shed creepage: total = Σ(vertical height + 2 × overhang) per shed. Example: 3 sheds at 5 mm height, 6 mm overhang = 3 × (5 + 12) = 51 mm effective creepage. This allows compact designs—a 25 mm diameter ribbed insulator can achieve the same creepage as a 40 mm plain cylinder, critical for space-constrained MV panels.

Q7: What material group should I specify for epoxy insulators in MV switchgear?

Material Group IIIa (CTI 175-249 per IEC 60112) is standard for filled epoxy resins used in MV switchgear components—contact boxes, post insulators, wall bushings. Group I (CTI ≥600) is for high-performance ceramics, rarely needed at MV voltages. Group IIIb (CTI 100-174) is for lower-grade plastics, unsuitable for MV primary insulation. When RFQ specifications omit material group, suppliers may default to Group II (CTI 400-599), which requires less creepage than IIIa but costs more and provides no functional benefit for typical MV applications. Explicitly specifying “Material Group IIIa per IEC 60664-1” ensures correct creepage tables are applied and avoids unnecessary cost.