Need Full Specifications?

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

Download our 2025 Product Catalog for detailed drawings and technical parameters of all switchgear components.

Get Catalog

One portfolio covering the full spectrum of indoor medium-voltage switching. Choose the vs1 vacuum circuit breaker(ZN63) for standard 12kV–24kV distribution in KYN28 panels, or upgrade to the LZND Electric Repulsion VCB for ultra-fast switching and a mechanical life of 300,000 operations.

This series offers a unified platform for indoor medium-voltage protection, covering both standard distribution and severe industrial duty. It includes the industry-standard VS1 (ZN63) for general applications and the specialized LZND series for high-frequency switching, ensuring optimal performance in KYN28 and custom panels.

The standard VS1 models utilize a modular spring operating mechanism to deliver reliable switching for 12kV and 24kV utility networks. They are designed for cost-effective protection of feeders and transformers, with a mechanical life of up to 30,000 operations and short-circuit breaking capacity up to 31.5kA.

For demanding environments, the LZND models feature an advanced electric repulsion mechanism. This unique design separates normal closing from fault clearing, achieving an ultra-long life of 300,000 operations. It is the ideal maintenance-free solution for electric arc furnaces, mining hoists, and soft starters where standard breakers fail.

For a broader view of XBRELE’s vacuum circuit breaker solutions, please visit the vacuum circuit breaker pillar page .

Compare the technical parameters and dimensions of our Standard VS1 series and High-Endurance LZND series to select the right breaker for your switchgear.

VS1-12 is an indoor vacuum circuit breaker with a three-phase AC 50 Hz rated voltage of 12 kV. It is used as the protection and control unit of power grid equipment and power equipment of industrial and mining enterprises, suitable for frequent operation under rated operating current or short-circuit conditions.

The breaker adopts an integral design of the operating mechanism and the interrupter/insulation body, and can be supplied as a fixed installation unit or combined with a special propulsion mechanism to form a withdrawable handcart unit.

The table below is derived from the VS1-12 technical parameter sheet and summarizes the main electrical ratings.

Main technical parameters — VS1-12

Values according to the VS1-12 medium-voltage vacuum circuit breaker data sheet.

| No. | Item | Unit | VS1-12 |

|---|---|---|---|

| 1 | Rated voltage | kV | 12 |

| 2 | Rated frequency | Hz | 50 |

| 3 | Power frequency withstand voltage (1 min) | kV | 42 / 48 |

| 4 | Lightning impulse withstand voltage (peak) | kV | 75 / 85 |

| 5 | Rated short-circuit breaking current | kA | 20 / 25 / 31.5 / 40 |

| 6 | Rated current | A | 630 / 1250 / 1600 / 2000 / 2500 |

| 7 | Rated short-time breaking current (effective value) | kA | 20 / 25 / 31.5 / 40 |

| 8 | Rated peak breaking current (peak value) | kA | 50 / 63 / 80 / 100 |

| 9 | Rated short-circuit making current (peak value) | kA | 50 / 63 / 80 / 100 |

| 10 | Rated short-circuit current duration | s | 4 |

| 11 | Mechanical life | operations | 20,000 |

| 12 | Power frequency withstand voltage of secondary circuit (1 min) | V | 2000 |

| 13 | Rated operating sequence | — | O – 0.3 s – CO – 180 s – CO |

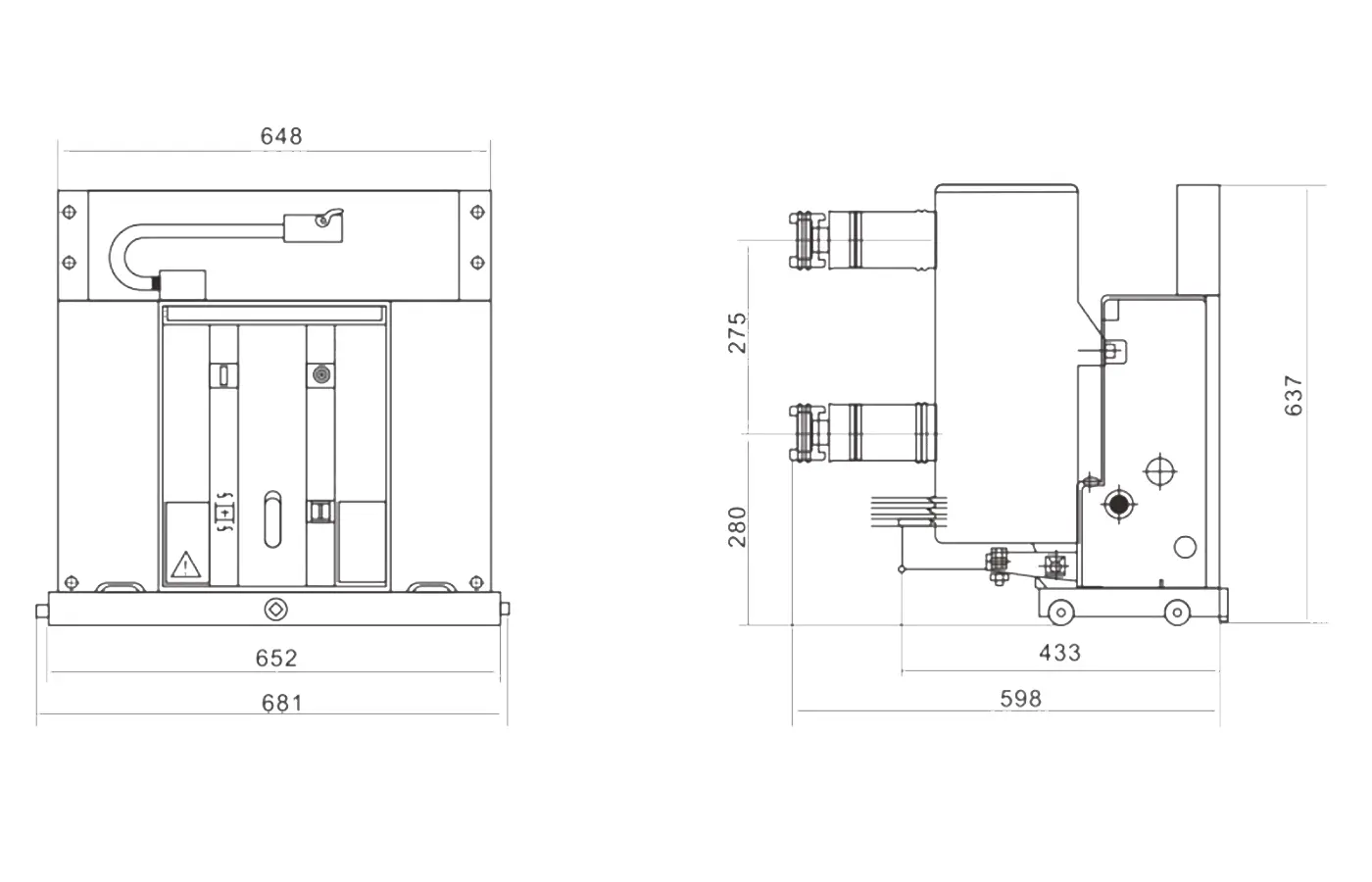

Outline & mounting dimensions — VS1-12

Outline and mounting dimensions of VS1-12 indoor vacuum circuit breaker for KYN28-type metal-clad switchgear.

| Item | Symbol | Value (mm) | Note |

|---|---|---|---|

| Overall height | H | — | Overall height of breaker assembly |

| Overall width | W | — | Including phase spacing |

| Depth | D | — | Total depth inside switchgear cubicle |

| Mounting hole spacing (horizontal) | L1 | — | Handcart or fixed base bolt spacing |

| Mounting hole spacing (vertical) | L2 | — | To match switchgear frame |

| Mounting hole size | Φ | — | Diameter of mounting bolts |

The LZND-12 is a new generation indoor vacuum circuit breaker designed for severe duty applications. It features a unique electric repulsion compensation mechanism that separates normal load closing from short-circuit closing.

This innovative design significantly reduces mechanism size and power requirements while achieving an incredible mechanical life of 300,000 operations. It is the ultimate choice for frequent switching in electric arc furnaces, soft starters, and mining hoists.

The table below summarizes the key technical parameters of the LZND-12/630-20U model.

Main technical parameters — LZND-12

Values according to the LZND-12 electric repulsion vacuum circuit breaker data sheet.

| No. | Item | Unit | LZND-12/630-20U |

|---|---|---|---|

| 1 | Rated voltage | kV | 12 |

| 2 | Rated frequency | Hz | 50 / 60 |

| 3 | Power frequency withstand voltage (1 min) | kV | 42 |

| 4 | Lightning impulse withstand voltage (peak) | kV | 75 |

| 5 | Rated short-circuit breaking current | kA | 20 |

| 6 | Rated current | A | 630 |

| 7 | Rated short-time withstand current (thermal) | kA | 20 |

| 8 | Rated peak withstand current (dynamic) | kA | 50 |

| 9 | Rated short-circuit making current (peak) | kA | 50 |

| 10 | Rated short-circuit duration | s | 4 |

| 11 | Mechanical life | ops | 300,000 |

| 12 | Closing time / Opening time | ms | 60 / ≤40 |

| 13 | Control voltage | V | AC/DC 220 |

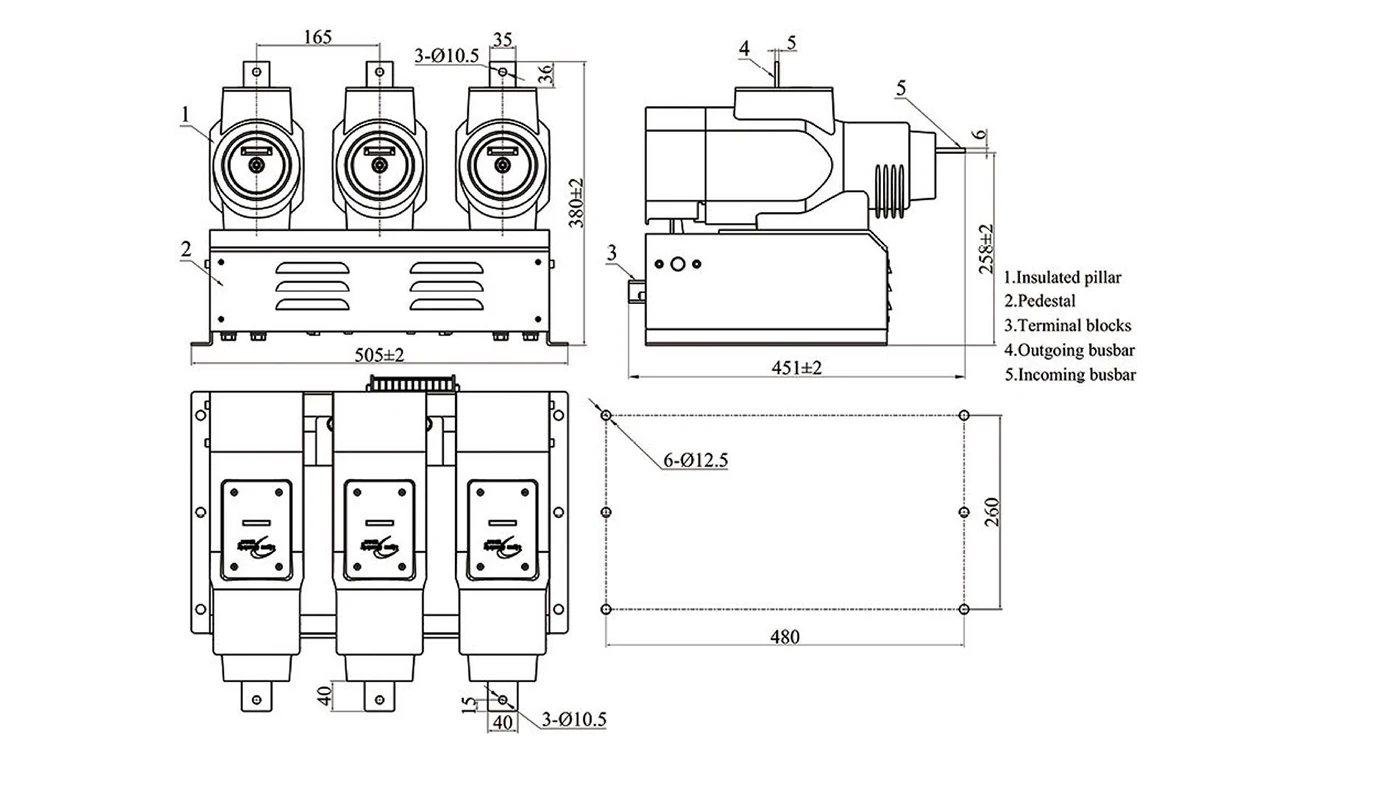

Outline & mounting dimensions — LZND-12

Compact installation dimensions for LZND-12 electric repulsion vacuum circuit breaker.

| Item | Value (mm) | Note |

|---|---|---|

| Overall Width | 480 | Compact width |

| Overall Depth | 451 | Including terminals |

| Overall Height | 380 | Pole top |

| Phase Spacing | 165 | (150/180/210 optional) |

| Mounting Hole (W) | 460 | Base width |

| Mounting Hole (D) | 286 | Base depth |

Whether you need standard protection for distribution networks (VS1) or specialized control for heavy industry (LZND), our indoor VCBs integrate seamlessly with relays and interlocking systems to form complete metal-clad switchgear solutions.

Build coordinated protection for both standard and severe-duty applications using VS1 or LZND breakers combined with modern relays.

Choose the operating mechanism that fits your duty cycle: standard spring for distribution or electric repulsion for frequent switching.

Designed for flexibility, our breakers fit into new panels or serve as high-performance upgrades for existing installations.

Behind every VS1 and LZND unit there is a controlled manufacturing flow – from vacuum interrupter inspection to routine testing – designed to ensure long-term reliability in metal-clad switchgear applications.

XBRELE manufactures the vacuum interrupter assemblies, mechanism and breaker body in a coordinated process. Each step is monitored and recorded for traceability of every VS1 and LZND circuit breaker.

Vacuum interrupters are checked for contact stroke, over-travel, contact resistance and vacuum integrity before assembly.

Interrupters are built into insulated pole units (VS1) or embedded poles (LZND) to provide stable dielectric performance in service.

The operating mechanism (spring or electric repulsion) is assembled and adjusted so opening/closing speeds and bounce times remain within strict limits.

Breaker poles and mechanism are mounted on a withdrawable handcart or fixed frame and matched with the KYN28 switchgear interface.

Each breaker passes electrical, mechanical and dielectric tests before packing, with serial numbers linked to quality records.

Electrical routine tests verify insulation level and switching performance of each pole.

Routine-test records can be supplied together with the delivery if required.

FAT / QAP / ITP witness testing can be arranged for utility and EPC projects on request.

XBRELE delivers both standard VS1 breakers and specialized LZND units worldwide. We provide export-grade packing and technical support to ensure your indoor switchgear projects run smoothly.

We maintain stock of common VS1 components for fast assembly, while specialized LZND units are built to order.

All breakers are packed to withstand long-distance transport, ensuring mechanism integrity upon arrival.

Our engineering team assists with integration into KYN28 panels and custom industrial cabinets.

The answers below cover typical questions from panel builders, EPC contractors and utilities when selecting and applying VS1 indoor vacuum circuit breakers.

VS1 indoor vacuum circuit breakers are mainly used in metal-clad switchgear such as KYN28-12 / KYN28-24 panels for medium-voltage distribution systems.

VS1 breakers are designed and type-tested according to international and national standards for high-voltage AC circuit breakers, typically including:

Rated current and breaking capacity must be coordinated with the system short-circuit level and the load of the feeder or transformer.

For complex projects, XBRELE can review single-line diagrams and fault level calculations to help confirm the correct VS1 rating.

The VS1 spring operating mechanism can be supplied with different control voltages and auxiliary circuits to match the switchgear design.

Compared with oil or SF6 breakers, VS1 vacuum circuit breakers require only limited routine maintenance, but periodic checks are still important.

For critical substations, condition-based monitoring and periodic diagnostic testing can be added to extend service life and improve reliability.

VS1 breakers are mainly designed for use in Chinese and international metal-clad switchgear such as KYN28-type panels, and can in some cases be adapted as a replacement in panels originally equipped with other brands.

For any replacement of ABB, Schneider, Siemens, Eaton or other OEM breakers, XBRELE recommends providing panel drawings, photos and nameplate data so that a detailed compatibility check can be carried out before offering a retrofit solution.